Quantum wax scale treatment integrated device special for oil field

A quantum, wax scale technology, applied in vibration generating devices, cleaning appliances, wellbore/well components, etc., can solve the problems of affecting the wax scale removal effect, non-existence, insufficient sonic vibration energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

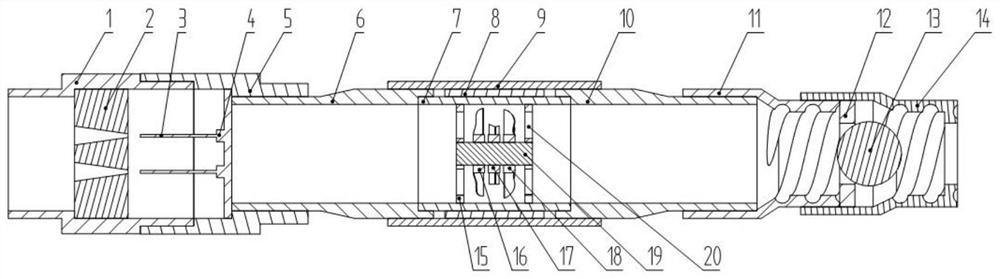

[0034] Example 1, reference Figure 1-8 According to a special quantum wax scale treatment of oilfield, including a jet vibrating assembly, a quantum-cavitation assembly attached to the right side of the jet vibrating assembly, fixedly connected to a vortex jet assembly on the right side of the quantum airborne assembly, quantum The internal fixation of the cavitation assembly has a reflow mixing component;

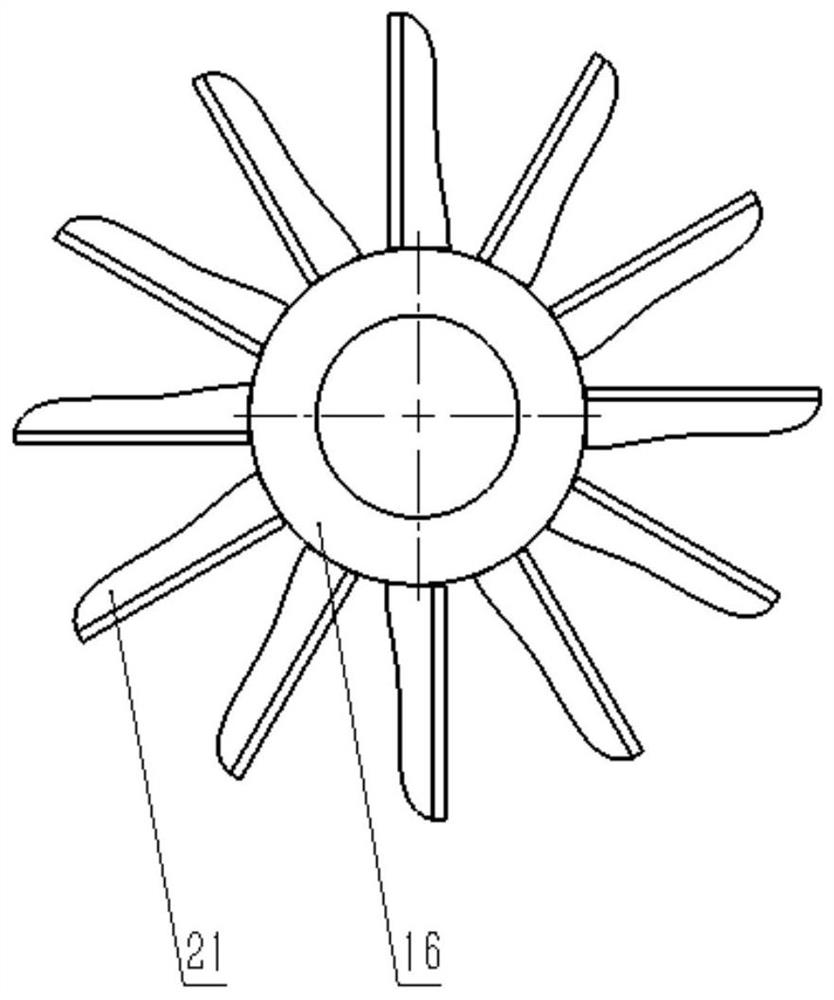

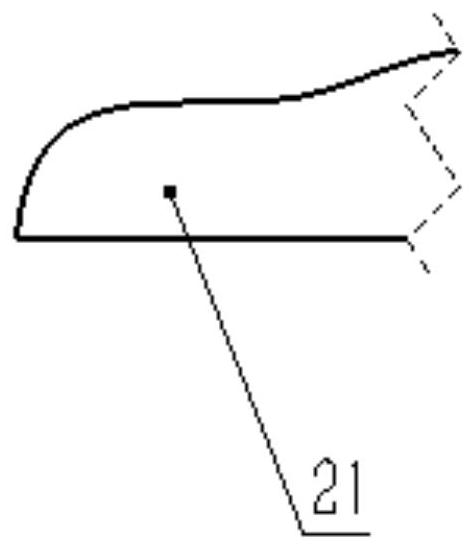

[0035]The return assembly includes a fixed shaft 19, and the fixed shaft 19 is fixed to the first fixing frame 15 and the second fixing frame 20, respectively, and the fixed shaft 19 is rotated by left to right by left to right, and there is a first guide 16, second Directors 17 and third guides 18;

[0036] The first fixing frame 15 and the second fixing frame 20 are fixedly connected inside the quantum cavitation assembly;

[0037] A first variable fastener 6 is provided between the jet and the quant sub-airized assembly, and the quantum air-conditioning assembly is provided...

Embodiment 2

[0046] Example 2, reference Figure 9 As shown, the difference from the present embodiment and the first embodiment is only that the inner wall of the first shift joint 6 is fixedly connected to the retreat ring 24, and the left side of the stop ring 24 is fitted with a guide ball 25. At the start of the oil pipeline, the oil pressure in the oil pipeline is smaller. As the start time is extended, the hydraulic pressure in the pipe is gradually increased. When the pressure reaches a certain degree, the guide ball 25 is pushed up, and the guide ball 25 and the return flow. The petroleum between the mixing assemblies is extruded and moved to the reflux mixing assembly, push the first guide, the second guide, and the third guide rotation. As the pressure in the conduit is further increased, the passage ball 25 is contrary to the fixed shaft 19 end, and the petroleum is passed by the gap between the passage ball 25 and the first shift joint 6, and is compared to the first embodiment, Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com