Metal metasurface filter for thermophotovoltaic

A metasurface and thermophotovoltaic technology, which is applied in instruments, optics, filters, etc., can solve the problems of small feature size of metal metasurface filters, narrow high reflection band of photonic crystal filters, and high cost of preparation methods, so as to improve the The effect of photoelectric conversion efficiency, low cost and low energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

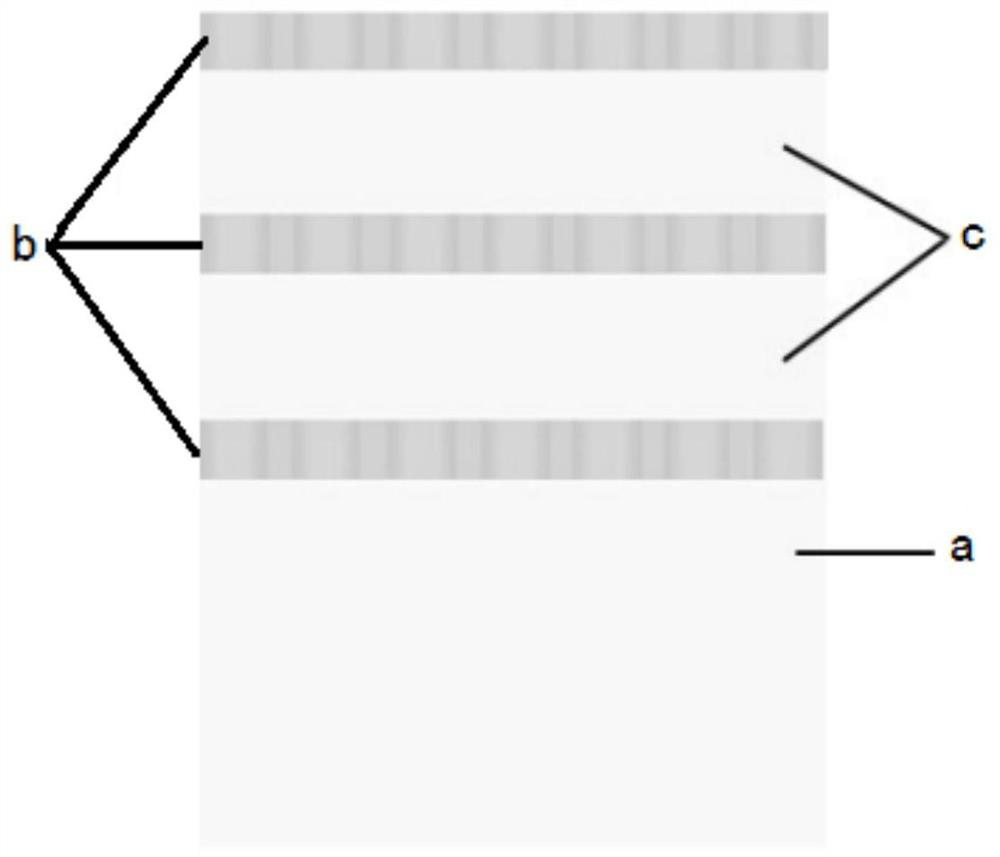

[0022] Specific implementation mode one: combine figure 1 and figure 2 This embodiment is specifically described. In this embodiment, a metal metasurface filter for thermal photovoltaics is composed of a transparent base layer and a noble metal film layer with a subwavelength hole structure;

[0023] One side of the transparent base layer is provided with 1 to 3 noble metal film layers with a subwavelength hole structure, and a filling layer is arranged between adjacent precious metal film layers with a subwavelength hole structure;

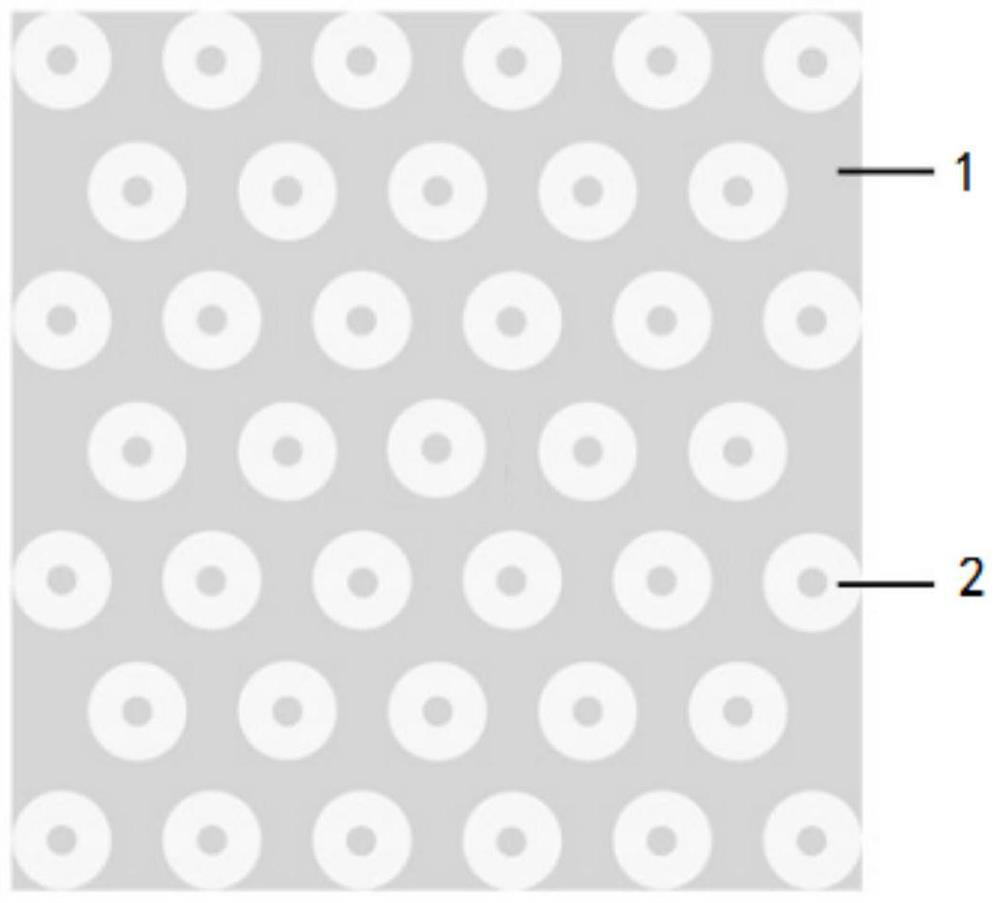

[0024] The noble metal film layer with a sub-wavelength hole structure is specifically a hexagonal arrangement of annular through holes on the noble metal film layer; the outer diameter of the annular through hole is 0.2 micron to 0.4 micron, and the inner diameter is 0.1 micron to 0.3 micron; In addition, the center-to-center spacing of adjacent circular through-holes is 0.6 micron to 1 micron.

[0025] The smaller the refractive index of the...

specific Embodiment approach 2

[0034] Embodiment 2: This embodiment differs from Embodiment 1 in that: the transparent base layer and the filling layer are both transparent materials with no optical absorption within the wavelength range of 0.4 microns to 3 microns. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0035] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: both the transparent base layer and the filling layer are magnesium fluoride. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com