Automatic detection and storage method for welding droplet data based on Fluent UDF

A technology of automatic detection and storage method, applied in the field of analog computing, to achieve the effect of improving welding heat input, reducing spatter rate and improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

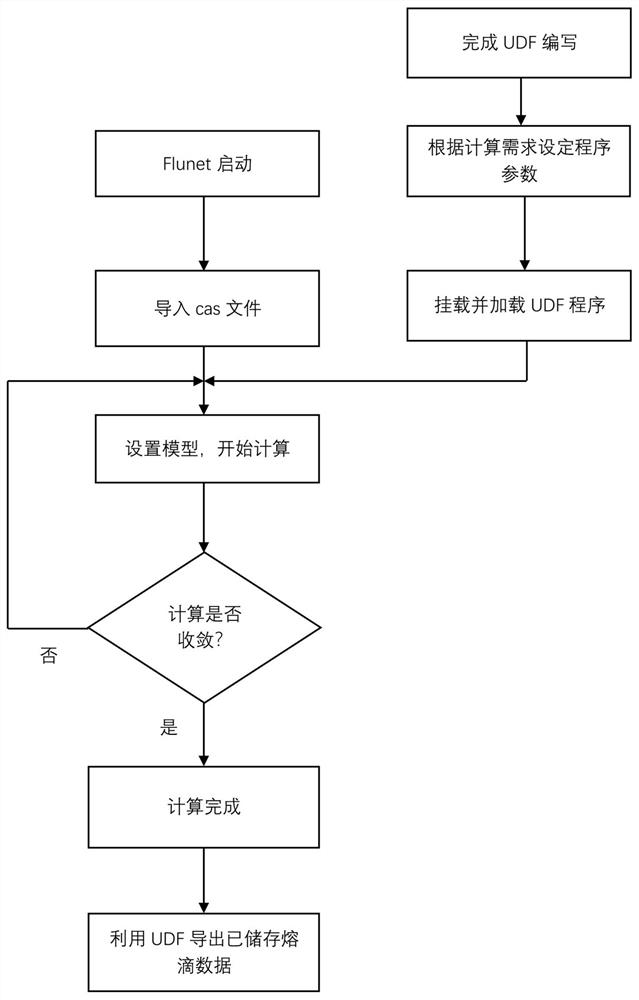

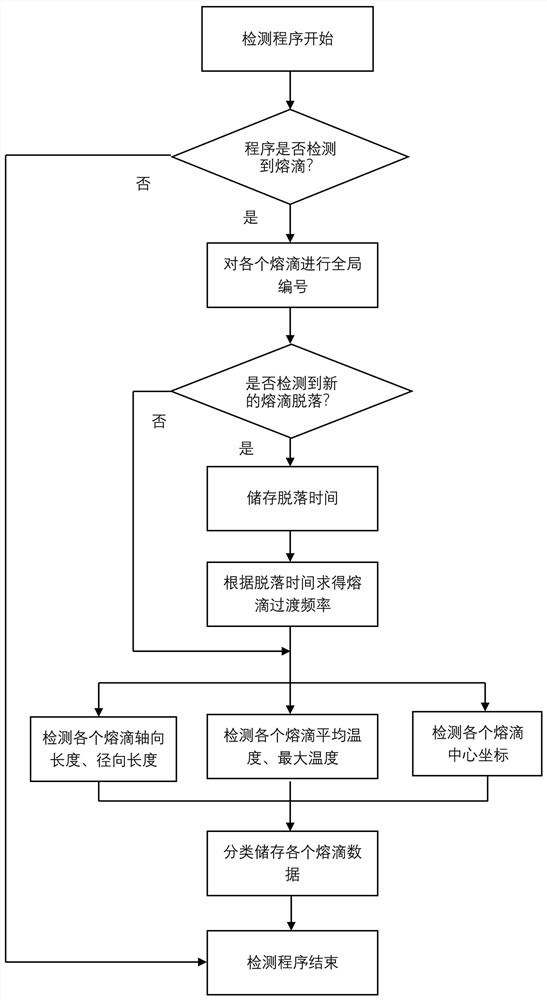

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

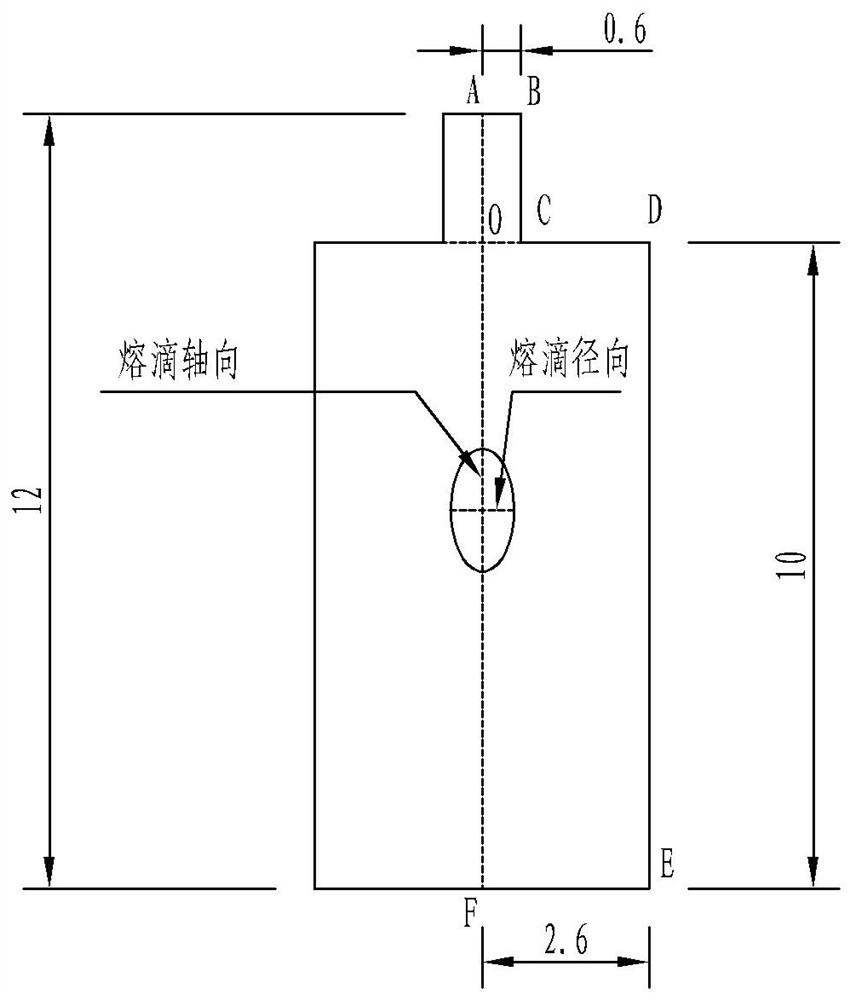

[0071] In this embodiment, the schematic diagram of the numerical model of molten inert gas shielded welding droplet transition is as follows Figure 4 As shown, the automatic detection and storage method of welding droplet data based on Fluent UDF is used to study the influence law and mechanism of welding parameters on each parameter of droplet. The welding parameters are shown in Table 1.

[0072] Table 1 welding parameters

[0073]

[0074] The model adopts a two-dimensional axisymmetric model, the shielding gas is pure argon, the welding wire is 304 stainless steel wire, the diameter of the welding wire is 1.2mm, AF is the symmetrical axis, the welding wire is fed from AB, CD is the shielding gas inlet, and DE and EF are the outlets. The first phase is set to argon, the second phase is set to molten steel, the fluid flow model is laminar flow,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com