Catalytic material for oxygen reduction and with gradient pore structure and preparation method thereof

A catalytic material and gradient pore technology, which is applied in the field of oxygen reduction catalytic materials with gradient pore structure and its preparation, can solve the problems of irregular morphology, increase the cost of material preparation, and difficult to control the morphology of intermediate products, etc. Effect of reduction activity, good oxygen reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing an oxygen reduction catalytic material with a gradient pore structure mainly includes the following steps.

[0030] 1) Weigh 1.00g of zinc nitrate hexahydrate into a 50mL beaker, add 30mL of deionized water and a magnet, stir and dissolve on a magnetic stirrer to obtain solution A, set aside.

[0031] 2) Dissolve 11.00g of 2-methylimidazole, 0.1g of iron phthalocyanine and 0.5g of silica template in 240mL of deionized water to obtain solution B.

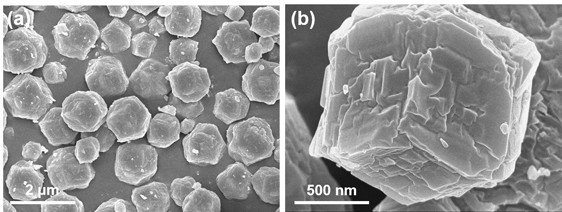

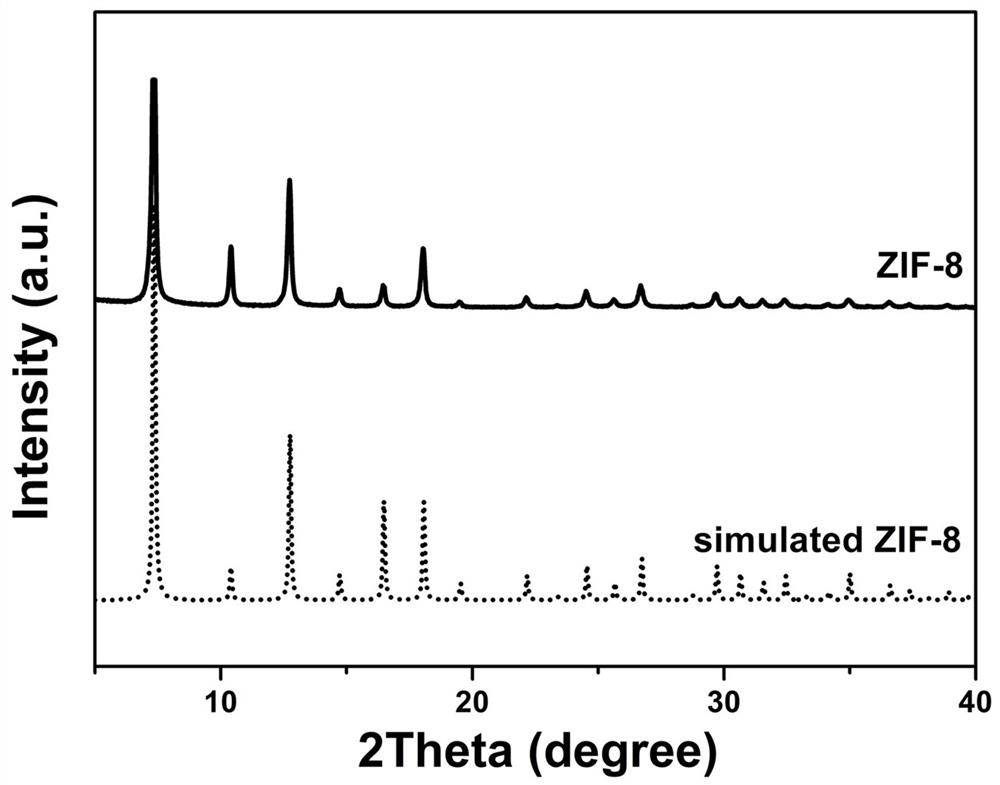

[0032] 3) Quickly add solution B to solution A with continuous magnetic stirring, stir at room temperature for 12 hours, centrifuge the solution 3 times with deionized water, wash 3 times with absolute ethanol, and dry under vacuum at 80°C to obtain a gray precursor material .

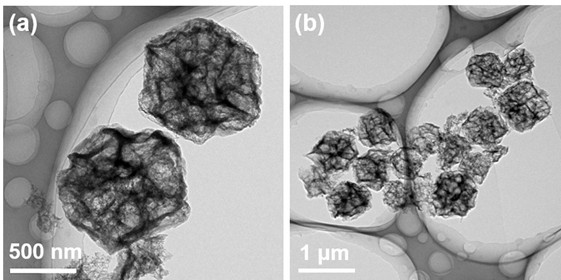

[0033] 4) Put the gray precursor obtained in step 3) in a high-temperature tube furnace, use high-purity argon as a protective gas, raise the temperature to 800°C at a rate of 3°C / min, and keep it for 150min. After the heat tre...

Embodiment 2

[0036] A method for preparing an oxygen reduction catalytic material with a gradient pore structure mainly includes the following steps.

[0037] 1) Weigh 1.50g of zinc nitrate hexahydrate into a 50mL beaker, add 30mL of deionized water and a magnet, stir and dissolve on a magnetic stirrer to obtain solution A, and set aside.

[0038] 2) Weigh 10.00g of 2-methylimidazole, 0.05g of iron phthalocyanine and 0.10g of silica template and dissolve in 150mL of deionized water to obtain solution B.

[0039] 3) Quickly add solution B into solution A with continuous magnetic stirring, stir at room temperature for 8 hours, centrifuge the solution 3 times with deionized water, wash 3 times with absolute ethanol, and dry under vacuum at 50°C to obtain a gray precursor material .

[0040]4) Put the gray precursor obtained in step 3) in a high-temperature tube furnace, use high-purity argon as a protective gas, raise the temperature to 1000°C at a rate of 6°C / min, and keep it for 90min. Af...

Embodiment 3

[0043] A method for preparing an oxygen reduction catalytic material with a gradient pore structure mainly includes the following steps.

[0044] 1) Weigh 1.19g of zinc nitrate hexahydrate into a 50mL beaker, add 30mL of deionized water and a magnet, stir and dissolve on a magnetic stirrer to obtain solution A, and set aside.

[0045] 2) Dissolve 11.82g of 2-methylimidazole, 0.08g of iron phthalocyanine and 0.36g of silica template in 180mL of deionized water to obtain solution B.

[0046] 3) Quickly add solution B to solution A with continuous magnetic stirring, stir at room temperature for 24 hours, centrifuge the solution 3 times with deionized water, wash 3 times with absolute ethanol, and dry under vacuum at 60°C to obtain a gray precursor material .

[0047] 4) Put the gray precursor obtained in step 3) in a high-temperature tube furnace, use high-purity argon as a protective gas, raise the temperature to 950°C at a rate of 5°C / min, and keep it for 120min. After the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com