Cooling liquid and machining chip separating and recycling device for machine tool

A technology for separation, recovery, and cooling liquid, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as increasing production costs, and achieve the effects of reducing production costs, large irradiation area, and good sterilization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

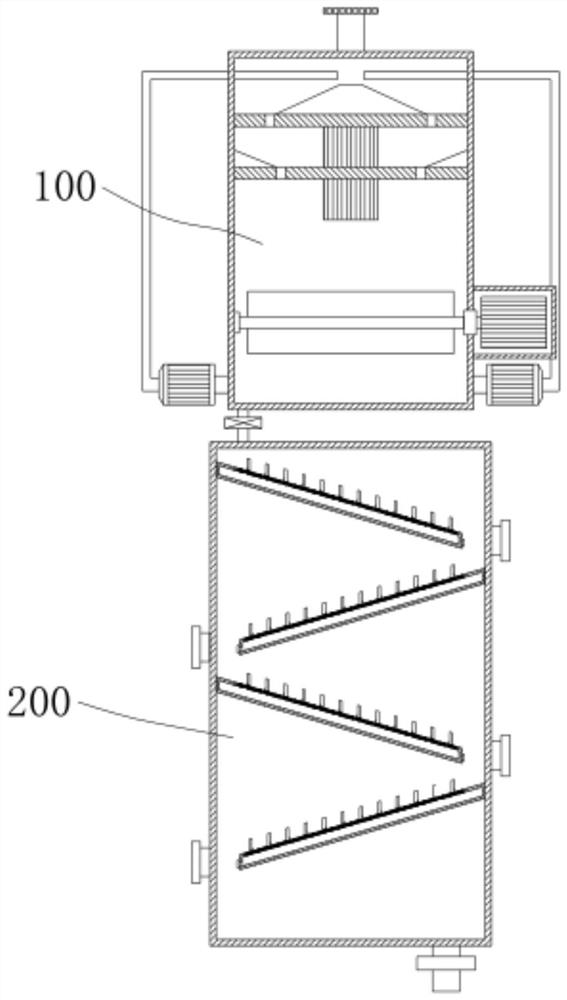

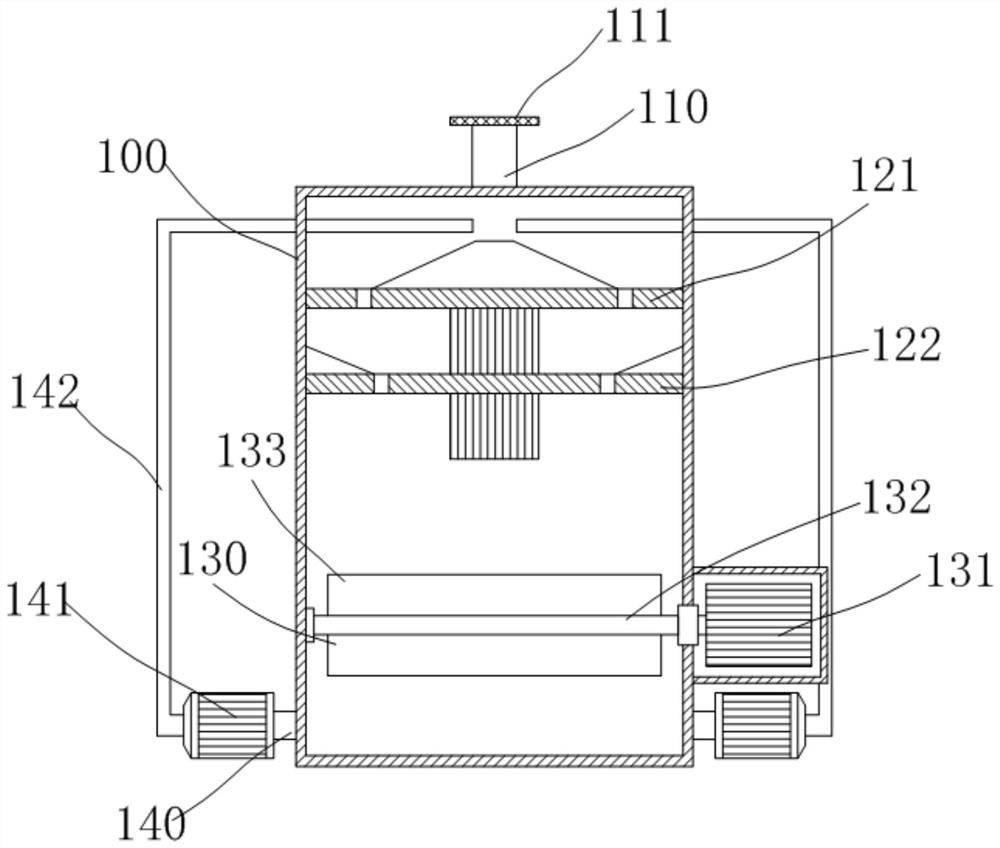

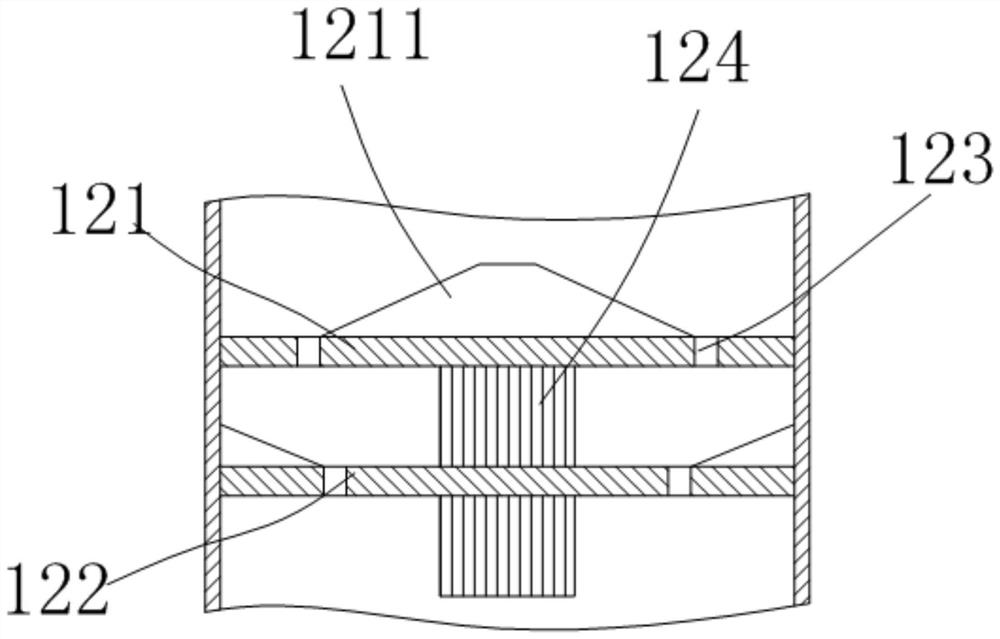

[0031]The present invention provides a technical solution: a machine tool coolant and processing debris separation and recovery device, including a liquid inlet box 100, the upper end of the liquid inlet box 100 is provided with a liquid inlet 110, and a foreign matter filter is movably installed on the liquid inlet 110 111, a first liquid receiving pan 121 and a second liquid receiving pan 122 are vertically spaced in the liquid inlet tank 100, and are connected to the inner wall of the liquid inlet tank 100, and a tapered block 1211 is arranged in the middle of the upper end of the first liquid receiving pan 121, The conical block 1211 corresponds to the liquid inlet 110, the first liquid receiving tray 121 and the second liquid receiving tray 122 are respectively provided with a liquid drop ring groove 123, and the first liquid receiving tray 121 and the second liquid receiving tray 122 are respectively provided with a drop ring groove 123. The array is provided with several...

Embodiment 2

[0035] Cooling mechanism 130 comprises rotating shaft 132, stirring rod, cooling plate 133 and motor 131, rotating shaft 132 is arranged in the liquid inlet box 100, and rotating shaft 132 is provided with several groups of stirring rods, and each group of stirring is provided with cooling plate 133, cooling The plate 133 has a cavity, and a cooling copper pipe is arranged in the cavity, and a motor 131 is fixedly installed at the lower end of the liquid inlet tank 100, and the output shaft of the motor 131 is drivingly connected to the rotating shaft 132;

[0036] There are infusion ports 140 on both sides of the bottom of the liquid inlet tank 100. A pump body 141 is installed outside the infusion port 140. The output end of the pump body 141 is connected to a liquid return pipe 142. The liquid return pipe 142 extends upward, and the liquid return pipe 142 passes through the liquid inlet. The tank 100 is above the first tapered block 1211 .

[0037] Specifically, the coolant...

Embodiment 3

[0039] The first run-off plate 231 and the second run-off plate 232 are all made up of an upper plate 233 and a lower plate 234, and the upper plate 233 and the lower plate 234 form a frame-shaped plate with a cavity through the connecting plate 235, and the upper plate 233 collects scrap There is a gap below the groove, and the upper plate 233 is provided with a lower side groove 2331 on one side of the gap, and the upper layer plate 233 is provided with an upper side groove 2332 on the other side of the gap, and a material receiving plate 2333 is movable in the lower side groove 2331. The plate 2333 extends into the upper groove 2332, the lower groove 2331 is provided with a spring set 2334, one end of the spring set 2334 is connected to the inner wall of the lower groove 2331, and the other end is connected to the receiving plate 2333;

[0040] The liquid blocking plate 237 is provided with a pushing block 238 on the side close to the gap, the pushing block 238 has an inclin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com