Preparation method of flexible composite film with hydrophobicity and low dielectric constant

A low dielectric constant and composite film technology, which is applied in the field of dielectric composite material preparation, can solve problems such as poor adhesion, and achieve the effects of large static contact angle, reduced dielectric constant, and low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Step 1, prepare the strain rate sensitive matrix:

[0041] Step 1.1, boric acid (H 3 BO 3 ) is heated at 180°C for 2 hours to prepare pyroboric acid;

[0042] Step 1.2, mix pyroboric acid, dimethylsiloxane and isopropanol, stir in a vacuum kneader at 180°C for 2 hours, and cool the final product to room temperature to obtain a polyborosiloxane (PBDMS) polymer matrix; where , the mass ratio of pyroboric acid, dimethylsiloxane and isopropanol is: 1.5:8:0.5

[0043] Step 2, preparing a hydrophobic P(VDF-TrFE)-PBDMS low dielectric constant flexible composite film.

[0044] Step 2.1 Weigh raw materials according to the following mass ratio: P(VDF-TrFE):PBDMS=65:35;

[0045] Step 2.2 Dissolve P(VDF-TrFE) in the organic solvent DMF, and stir continuously for 6 hours to obtain mixed solution A; wherein, 5.4145 g of P(VDF-TrFE) is required for every 100 mL of DMF;

[0046] Step 2.3 Dissolve PBDMS in isopropanol, and stir continuously for 6-12h to obtain mixed solution B; wh...

Embodiment 2

[0054] Step 1, prepare the strain rate sensitive matrix:

[0055] Step 1.1, boric acid (H 3 BO 3 ) is heated at 180°C for 2 hours to prepare pyroboric acid;

[0056] Step 1.2, mix pyroboric acid, dimethylsiloxane and isopropanol, stir in a vacuum kneader at 180°C for 2 hours, and cool the final product to room temperature to obtain a polyborosiloxane (PBDMS) polymer matrix; where , the mass ratio of pyroboric acid, dimethylsiloxane and isopropanol is: 1.5:8:0.5;

[0057] Step 2, preparing a hydrophobic P(VDF-TrFE)-PBDMS low dielectric constant flexible composite film.

[0058] Step 2.1 Weigh raw materials according to the following mass ratio: P(VDF-TrFE):PBDMS=80:20;

[0059] Step 2.2 Dissolve P(VDF-TrFE) in the organic solvent DMF, and stir continuously for 6-12h to obtain mixed solution A; wherein, 6.664g of P(VDF-TrFE) is required for every 100mL of DMF;

[0060] Step 2.3 Dissolve PBDMS in isopropanol, and stir continuously for 6-12h to obtain mixed solution B; wherein,...

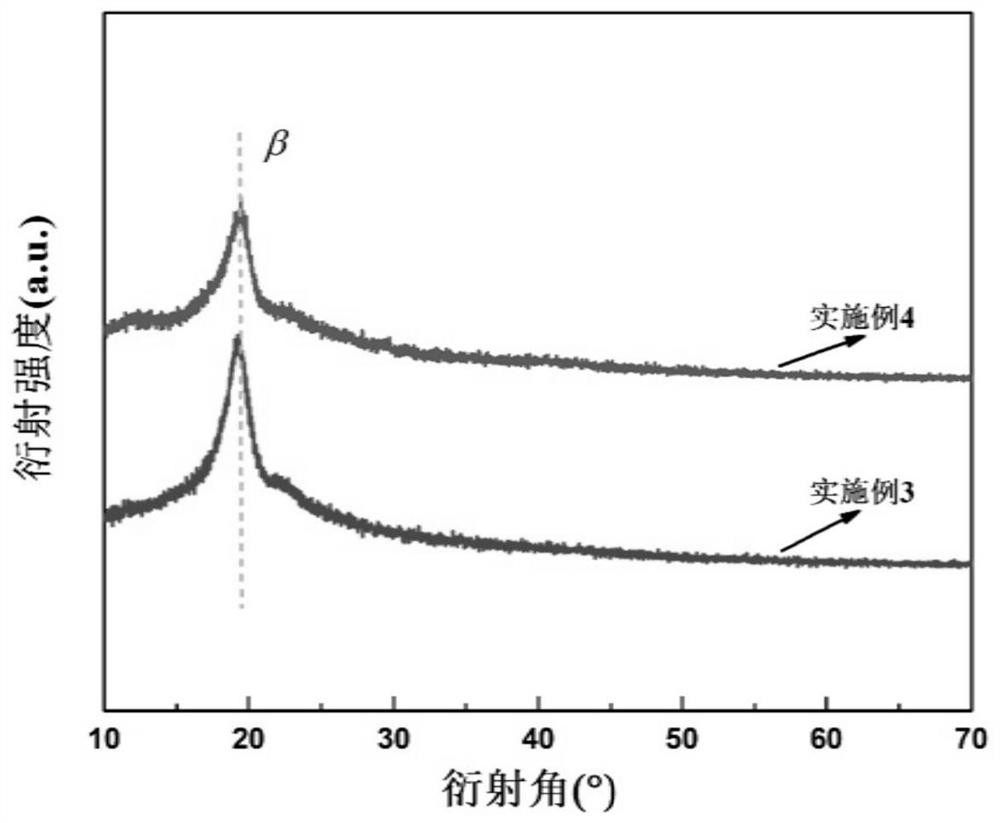

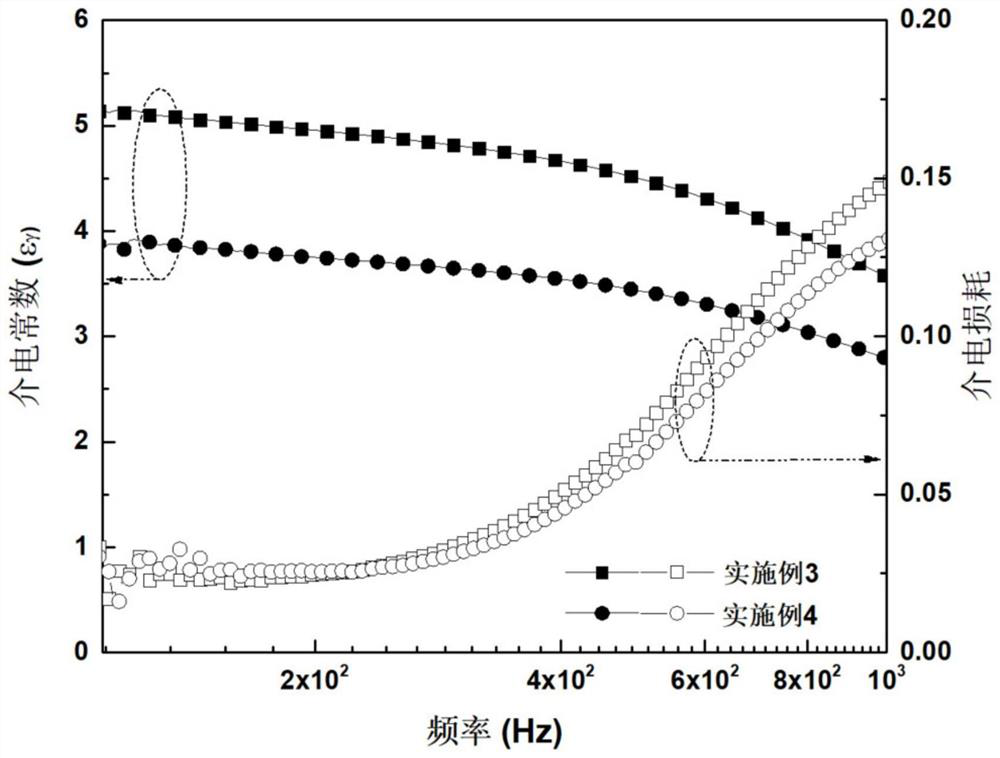

Embodiment 3

[0068] Step 1, prepare the strain rate sensitive matrix:

[0069] Step 1.1, boric acid (H 3 BO 3 ) is heated at 180°C for 2 hours to prepare pyroboric acid;

[0070] Step 1.2, mix pyroboric acid, dimethylsiloxane and isopropanol, stir in a vacuum kneader at 180°C for 2 hours, and cool the final product to room temperature to obtain a polyborosiloxane (PBDMS) polymer matrix; where , the mass ratio of pyroboric acid, dimethylsiloxane and isopropanol is: 1.5:8:0.5;

[0071] Step 2, preparing a hydrophobic P(VDF-TrFE)-PBDMS low dielectric constant flexible composite film.

[0072] Step 2.1 Weigh raw materials according to the following mass ratio: P(VDF-TrFE):PBDMS=85:15;

[0073] Step 2.2 Dissolve P(VDF-TrFE) in the organic solvent DMF, and stir continuously for 6-12h to obtain mixed solution A; wherein, 7.0805g of P(VDF-TrFE) is required for every 100mL of DMF;

[0074] Step 2.3 Dissolve PBDMS in isopropanol, and stir continuously for 6-12h to obtain mixed solution B; where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com