Titanium dioxide/polymer composite dielectric hydrophobic material and preparation method

A technology of titanium dioxide and hydrophobic materials, applied in the direction of coating, etc., can solve the problems of limited application and low dielectric constant, and achieve the effects of low glass transition temperature, increased dielectric constant, and excellent surface hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

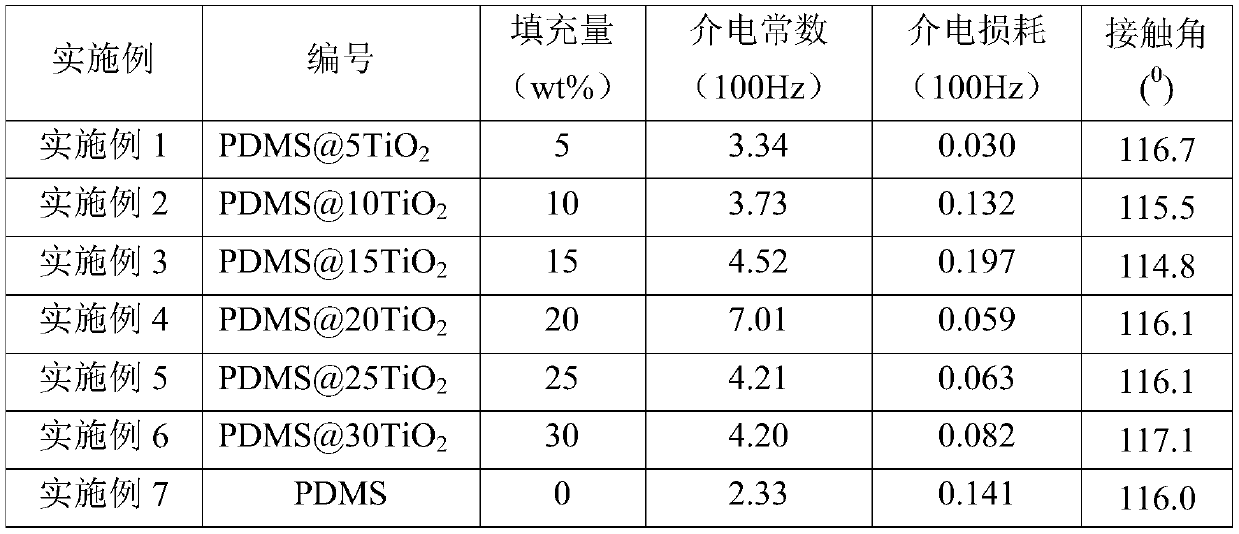

Embodiment 1-6

[0022] (1) 2.5 grams of titanium dioxide, 12.5 milliliters of absolute ethanol, 12.5 milliliters of absolute ethylene glycol, and 100 milliliters of concentration of 10 mol / liter sodium hydroxide are placed in a 200 milliliter hydrothermal reaction kettle, stirred for 10 minutes, and ultrasonically treated for 10 minutes minutes, and stir for another 10 minutes. Then the reaction kettle was put into a blast drying oven to react at a constant temperature of 180°C for 48 hours;

[0023] (2) After the reaction is over, take out the precipitate, soak it with 37wt% concentrated hydrochloric acid for 6 hours, wash the soaked precipitate with deionized water several times, and move it to a 60°C oven for drying to obtain the precursor H 2 Ti 3 o 7 ;

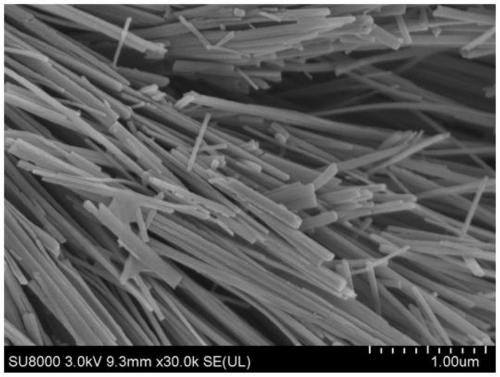

[0024] (3) The precursor H 2 Ti 3 o 7 Burning in the air for 2 hours, the burning temperature is 600°C, and the heating rate is 5°C / min, to obtain white relatively fluffy titanium dioxide powder (its microstructure is linear, such ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com