High-dielectric-constant full-organic composite hydrophobic material and preparation method thereof

A high dielectric constant, hydrophobic material technology, applied in the field of nanocomposites, can solve the problem of low hydrophobic characteristics, achieve the effect of increasing the dielectric constant, high operability, and enhancing the interface polarization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

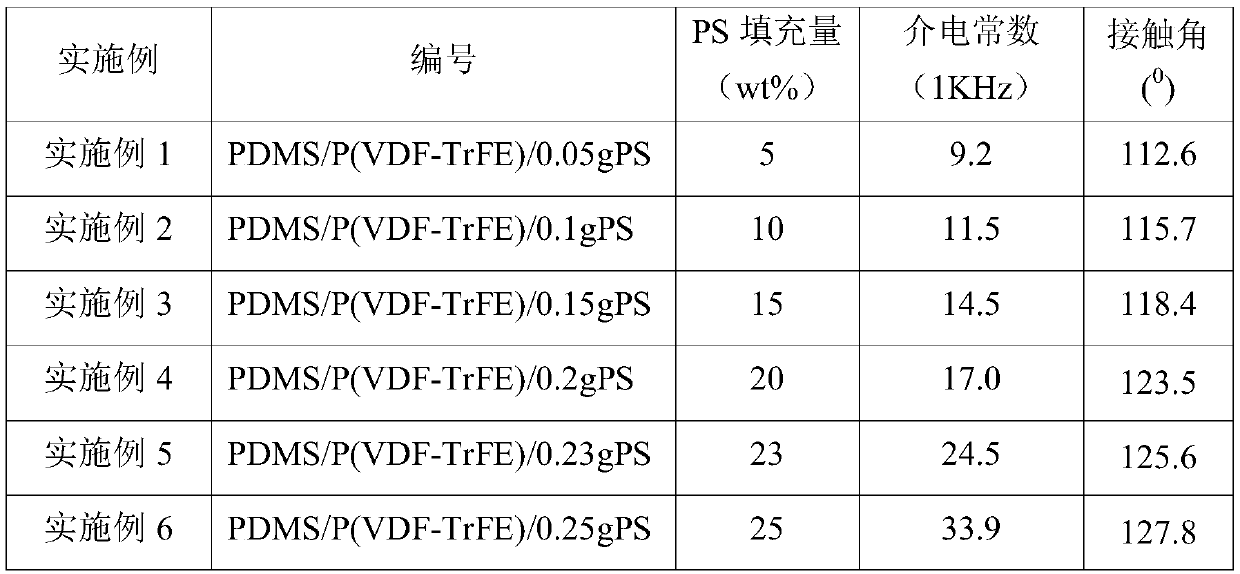

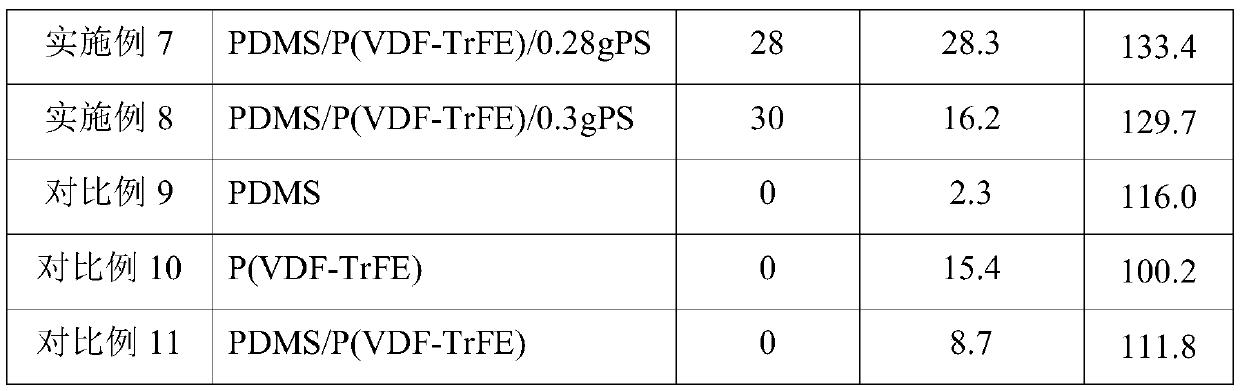

Embodiment 1-8

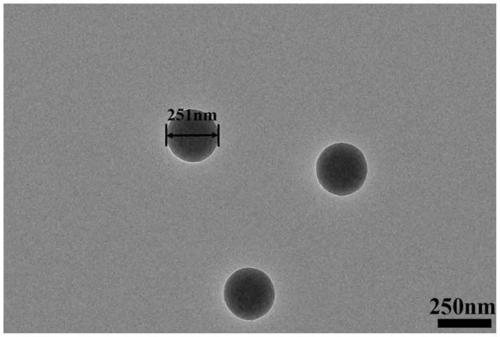

[0025] (1) Add 1.5 g of polyvinylpyrrolidone (PVP) and 100 mL of deionized water into a three-necked flask for mechanical stirring. Secondly, under the condition of continuously injecting nitrogen, 10 g of styrene (C 8 h 8 ) into a three-necked flask placed in a water bath at 70°C. Then, 0.25 g of 2,2-azobis(2-methylpropylimidium) dihydrochloride (AIBA) was added to the reaction apparatus and kept stirring for 24 hours. Finally, polystyrene microspheres (PS microspheres, with a particle size of about 251 nm, such as figure 1 shown).

[0026] (2) Dissolve poly(vinylidene fluoride-trifluoroethylene) powder (P(VDF-TrFE)) and PS microspheres in DMF (N,N-dimethylformamide) at a solute-solvent mass ratio of 1:10 And stir evenly to obtain solution A. Dissolve PDMS (polydimethylsiloxane) in isopropanol at a mass ratio of solute to solvent of 1:5 and stir evenly to obtain solution B.

[0027] (3) Take solution A and solution B according to the mass ratio of poly(vinylidene fluori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com