Preparation method of ZSM-5 zeolite/polycrystalline iron fiber/resin composite adsorption material, and composite material and preparation method thereof

A technology of composite adsorption materials and resin composite materials, which is applied in the direction of chemical instruments and methods, silicon compounds, alkali metal compounds, etc., can solve the problems of reduced fiber magnetic permeability, reduced impedance matching characteristics, and complex processes, etc., to achieve easy large-scale The effect of promotion, low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

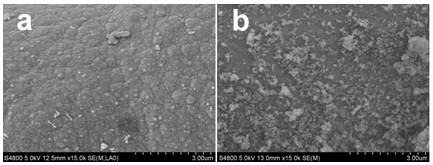

[0031] Add 5 g of polycrystalline iron fibers to 50 mL of dilute ammonia water with a volume concentration of 0.5%, stir for 30 minutes and then filter to obtain polycrystalline iron fibers washed with ammonia water; add the polycrystalline iron fibers washed with ammonia water to 50 mL of PDDA with a content of 0.5 % 1mol / L NaCl solution, stirred for 30min, then suction filtered, and washed with dilute ammonia water for several times to obtain surface-modified polycrystalline iron fibers with positive charges.

[0032] Add 0.25g of ZSM-5 nano-crystal seeds with a particle size of 50-100nm into 25mL of dilute ammonia water with a volume concentration of 0.5% according to 1% mass ratio, ultrasonically disperse for 30min, and then add 2.5g modified Stir for 30 minutes mechanically, put the magnet on the side of the container beaker, layer, let it stand for 10 minutes, pour out the solution by pouring, remove the magnet, then add 25ml of dilute ammonia water with a volume concentr...

Embodiment approach 2

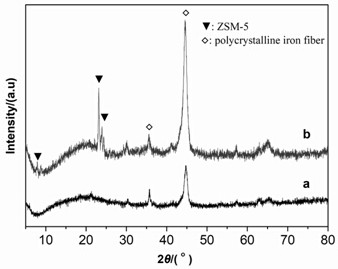

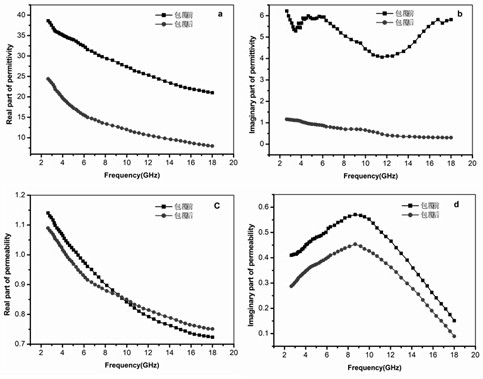

[0038] Prepare and test the ZSM-5 zeolite / polycrystalline iron fiber composite adsorption material according to the method and parameters shown in Embodiment 1, change the PDDA concentration to 0.1%, change the NaCl concentration to 0.5mol / L, and change the crystallization temperature and time to 80°C and 72h, the obtained ZSM-5 zeolite / polycrystalline iron fiber composite adsorption material has a dielectric constant in the range of 30-16 and a magnetic permeability in the range of 1.10-0.76.

Embodiment approach 3

[0040] Prepare and test the ZSM-5 zeolite / polycrystalline iron fiber composite adsorption material according to the method and parameters shown in Embodiment 1, the PDDA concentration is changed to 0.3%, the modified polycrystalline iron fiber is changed to 3.5g, and the crystallization temperature and time are changed to 90°C and 36h, the dielectric constant range of the obtained ZSM-5 zeolite / polycrystalline iron fiber composite adsorption material is 25-8, and the magnetic permeability range is 1.08-0.78.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com