Aluminum oxidation coloring device

An aluminum oxidation technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of slow electrolytic coloring speed, affecting industrial coloring efficiency, etc., and achieve the effect of improving vertical moving speed and air pressure stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

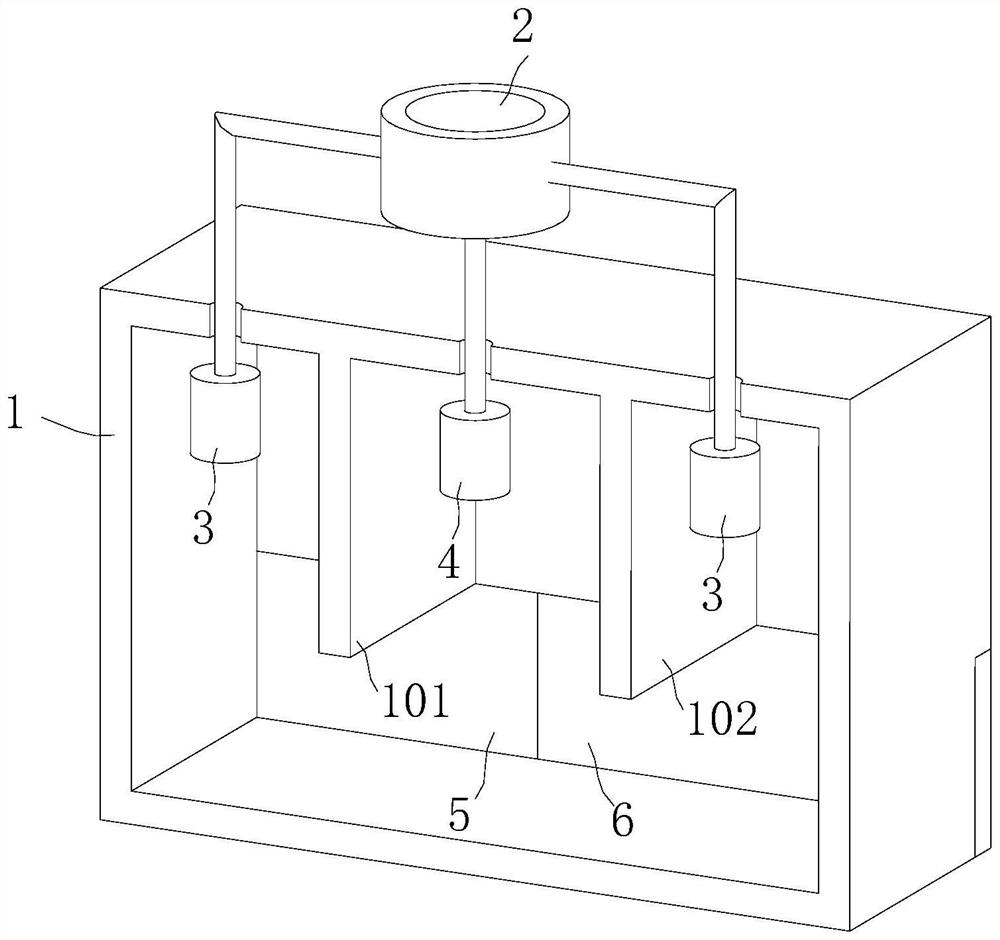

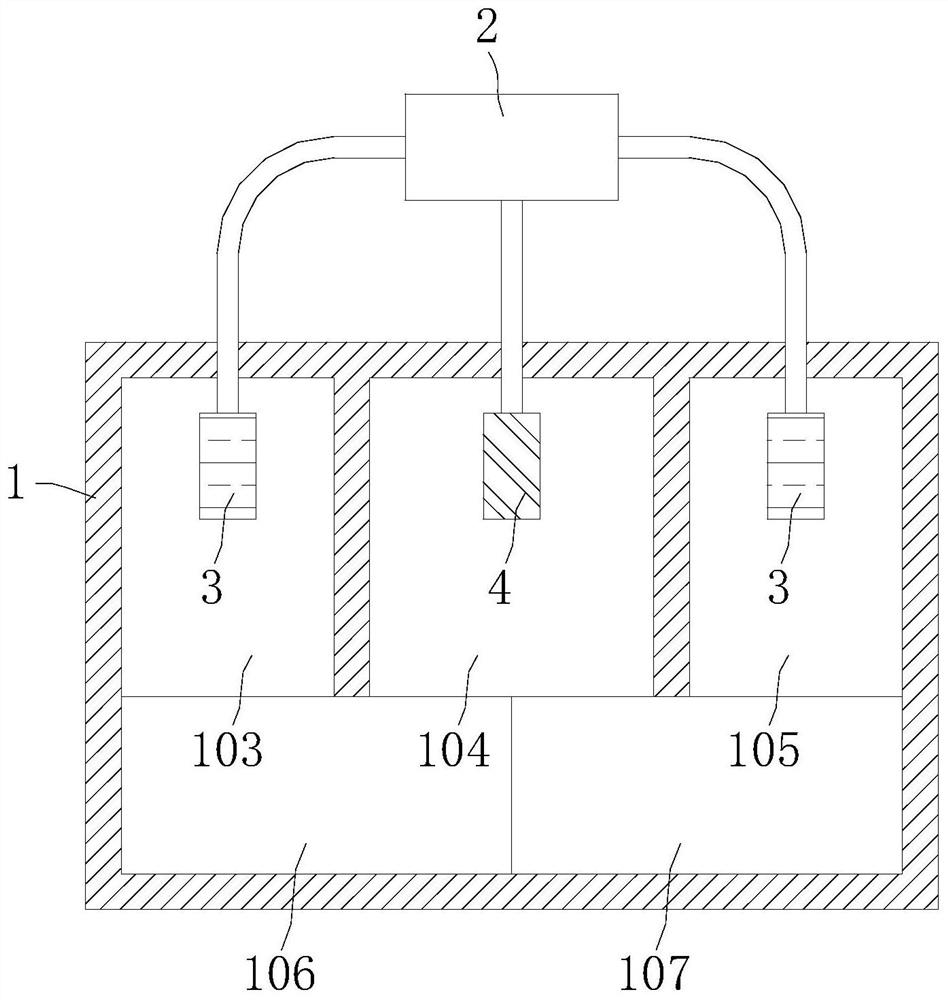

[0051] Specific embodiment one: please refer to Figure 1-5 An aluminum oxidation coloring device comprises a coloring tank 1, a power supply 2, an acceleration group 5 and an acceleration group 6.

[0052] Coloring tank 1 is filled with coloring liquid.

[0053] A sub-board 101 and two sub-boards 102 are arranged on the inner upper wall of the coloring tank 1 .

[0054] The first sub-board 101 and the second sub-board 102 divide the inner upper part of the coloring tank 1 into a male part 103 , a cathode part 104 and a male part 105 in sequence.

[0055] An anode material 3 is provided in both the first anode 103 and the second anode 105 , and the anode material 3 is connected to the positive pole 201 of the power supply 2 . The anode material 3 is graphite.

[0056] The cathode part 104 is provided with an aluminum plate 4 to be colored, and the aluminum plate 4 is connected to the negative pole 202 of the power supply 2 . The aluminum plate 4 to be colored is an anodize...

specific Embodiment 2

[0066] Specific embodiment two: on the basis of specific embodiment one, please refer to Figure 6 A coloring device for aluminum oxidation, the upper wall of the coloring tank 1 where the anode part 103, the cathode part 104 and the anode part 105 are located is provided with a plurality of ventilation holes 108. Facilitate the discharge of gas generated by electrolysis. Keep the air pressure in the coloring tank 1 stable.

specific Embodiment 3

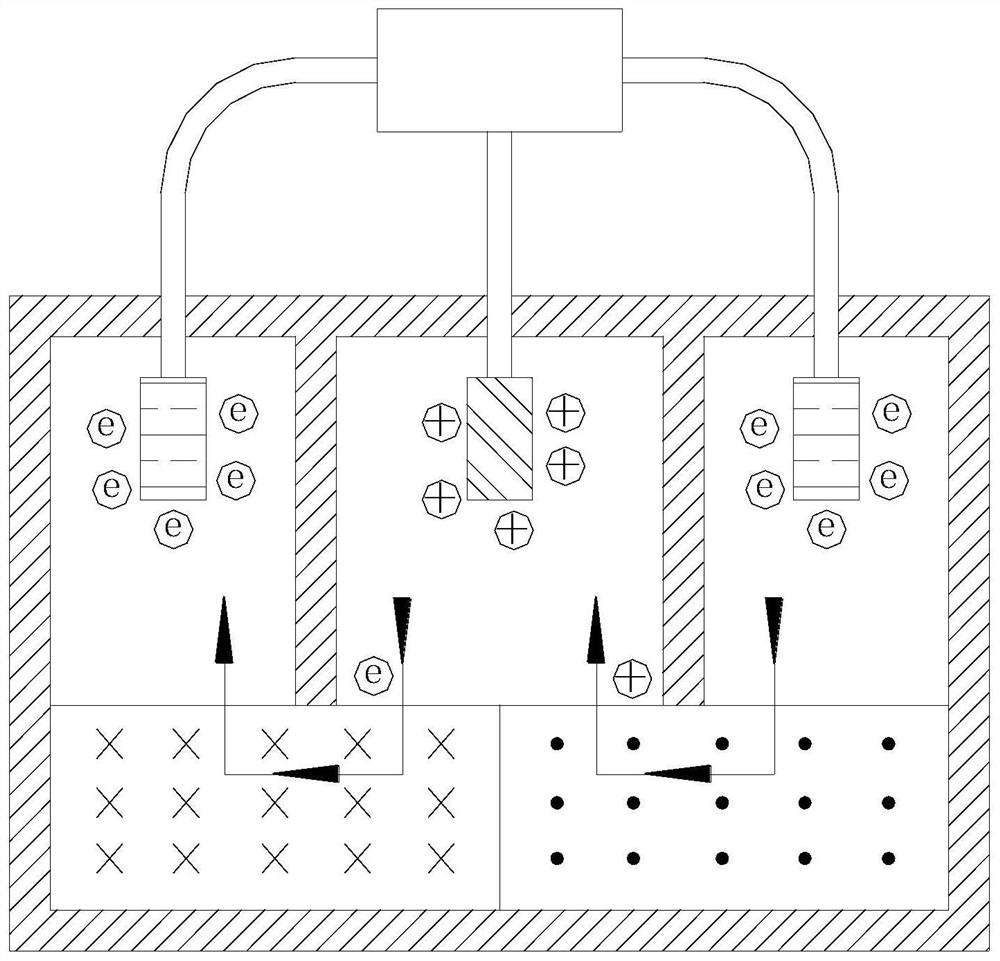

[0067] Specific embodiment three: on the basis of specific embodiment two, please refer to Figure 7-8 An aluminum oxidation coloring device, the upper wall of the coloring tank 1 where the cathode part 104 is located is provided with three groups of accelerations 7 .

[0068] Acceleration three groups 7 include negative electric plate, negative charge electrostatic generator and generation power supply. The negative plate is arranged on the upper wall of the coloring tank 1 where the cathode part 104 is located. The negative charge electrostatic generator is electrically connected with the generating power supply. Negative charge electrostatic generators make the negative plates carry a negative charge. The negative plate, which carries a negative charge, repels anions and attracts cations.

[0069] The negative plates carrying negative charges can accelerate the negative and positive ions in the cathode portion 104 . The negative ions in the cathode part 104 are accelera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com