Glass silver-zinc-loaded antibacterial agent and preparation method thereof

A glass-loaded silver and antibacterial agent technology, applied in botany equipment and methods, biocides, disinfectants, etc., can solve problems such as easy loss, uneven silver loading, and difficulty in controlling the release rate of silver

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of preparing glass-loaded silver-zinc antibacterial agent comprises:

[0031] Step 1: In parts by weight, 70 parts of phosphate, 5 parts of borate, 8 parts of molecular sieve, 5 parts of silver carbonate and 5 parts of zinc oxide are mixed, put into a mixer and mixed evenly to obtain a mixture;

[0032] Step 2: Put the mixture into the melting device, and the heating program is as follows: (1) 30°C to 300°C, 30min; heat preservation for 5-10min; (2) 300°C to 950°C, 120min; heat preservation for 30min; 950 to 1050°C ℃, keep warm for 60 minutes to obtain a melt, pour the melt into stainless steel or nickel-plating equipment, and cool the melt to obtain a glass body;

[0033] Step 3: Grinding the vitreous body to obtain the glass-loaded silver-zinc antibacterial agent, the particle size of the glass-loaded silver-zinc antibacterial agent is ≤10 μm.

[0034] The glass-loaded silver-zinc antibacterial agent is white powder, and the specific surface area...

Embodiment 2

[0036] Add the glass-loaded silver-zinc antibacterial agent prepared in Example 1 to polyethylene, and add 1 part of the glass-loaded silver-zinc antibacterial agent per 100 parts of polyethylene by weight. The addition method is to mix in the masterbatch, melt extrusion, and blow molding to form an antibacterial film.

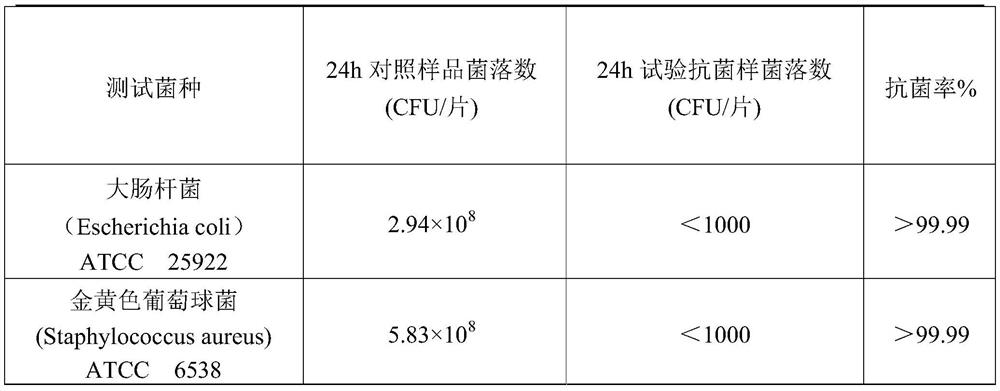

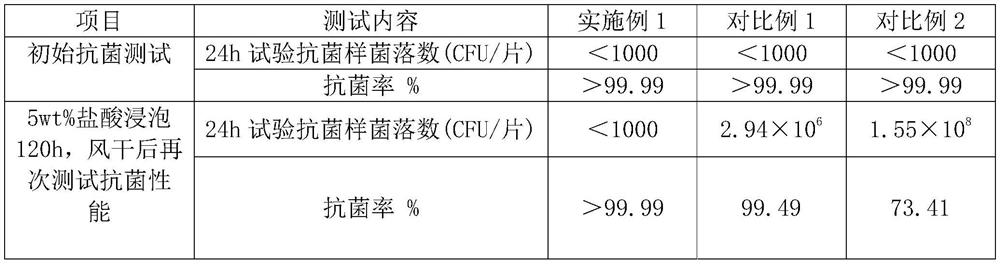

[0037] The antibacterial film has no visible difference from the film formed by pure polyethylene in appearance, and has good transparency. The results of the antibacterial test are shown in Table 1.

[0038] Table 1 Antibacterial performance test results table

[0039]

[0040] It can be seen from Table 1 that the film has excellent antibacterial properties and can be used in food packaging, daily necessities and other fields. Since the glass-loaded silver-zinc antibacterial agent prepared by the present invention belongs to inorganic additives, it has high safety and heat resistance, and excellent stability, and can be added to various resins to play an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com