Cashmere overcoat with high shape-preserving property and antibacterial function and manufacturing process thereof

A production process and shape-preserving technology, applied in the field of garment manufacturing, can solve problems such as affecting the packaging effect of cashmere, hidden dangers to consumers' health, affecting the quality of fabrics, etc., to achieve excellent anti-felt shrinkage effect, reduce self-damage, and improve steam shrinkage. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A cashmere overcoat with high shape retention and antimicrobial properties, cashmere face and lining.

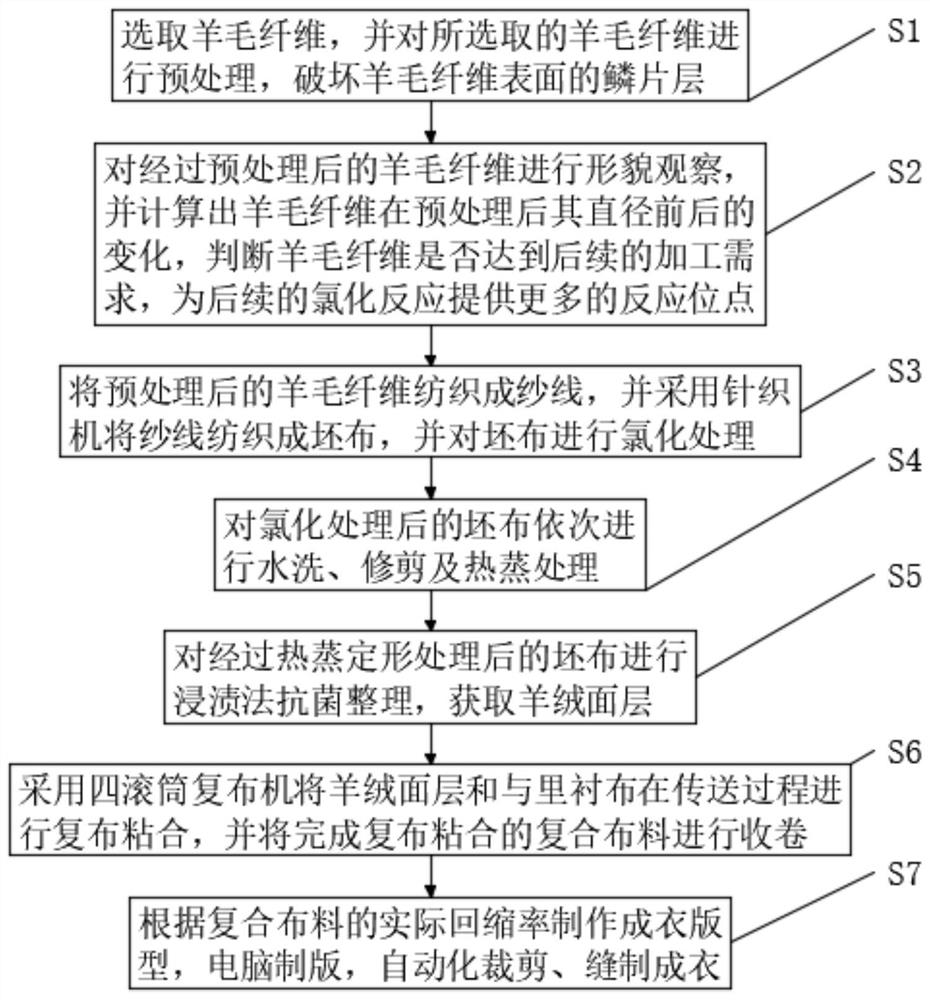

[0057] Specifically, such as figure 1 As shown, including the following process flow:

[0058] Step S1: selecting wool fibers and pretreating the selected wool fibers to destroy the scale layer on the surface of the wool fibers;

[0059] Step S2: Observing the appearance of the pretreated wool fiber, and calculating the change of the diameter of the wool fiber before and after the pretreatment, judging whether the wool fiber meets the subsequent processing requirements, and providing more information for the subsequent chlorination reaction. the reaction site;

[0060] Step S3: weaving the pretreated wool fiber into yarn, using a knitting machine to weave the yarn into gray cloth, and chlorinating the gray cloth;

[0061] Step S4: washing, trimming and steaming the gray cloth after the chlorination treatment in sequence;

[0062]Step S5: Perform antibacterial fini...

Embodiment 2

[0077] A cashmere overcoat with high shape retention and antimicrobial properties, cashmere face and lining.

[0078] Specifically, such as figure 1 As shown, including the following process flow:

[0079] Step S1: selecting wool fibers and pretreating the selected wool fibers to destroy the scale layer on the surface of the wool fibers;

[0080] Step S2: Observing the appearance of the pretreated wool fiber, and calculating the change of the diameter of the wool fiber before and after the pretreatment, judging whether the wool fiber meets the subsequent processing requirements, and providing more information for the subsequent chlorination reaction. the reaction site;

[0081] Step S3: weaving the pretreated wool fiber into yarn, using a knitting machine to weave the yarn into gray cloth, and chlorinating the gray cloth;

[0082] Step S4: washing, trimming and steaming the gray cloth after the chlorination treatment in sequence;

[0083] Step S5: Perform antibacterial fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com