Strain for degrading wool scale layer

A flake layer and wool technology, applied in the field of Pseudomonas, can solve the problems of increased protease process steps, time-consuming, increased cost, etc., and achieve the effects of avoiding environmental impact, mild working conditions, and good anti-felt performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

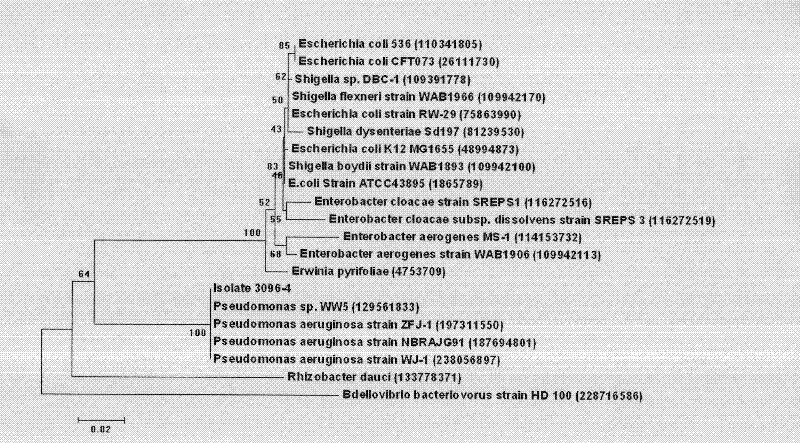

[0027] The new strain Pseudomonas sp. 3096-4 (Pseudomonas sp.3096-4) has been deposited in the General Microorganism Center of China Committee for the Collection of Microorganisms, and its preservation number is: CGMCC No.3888.

[0028] The source of the strain: the strain is derived from the rotten wool of the sheep farm in Songjiang, Shanghai. The specific isolation method is as follows:

[0029] (1) Enrichment Take 1g of rotten wool from the piled wool and place it in enrichment medium (0.5g of beef extract, 1g of peptone, 0.5g of sodium chloride, pH7.0-7.6), and culture at 28°C and 120 rpm 48h; then take 2mL of its culture solution and transfer it to enrichment medium 2, and further enrich and cultivate for 48h at 28°C and 120 rpm;

[0030] (2) Primary screening Take 100 μL of the final enrichment solution and spread it on the phosphoric acid digestion protein medium plate, and screen out the growing single colonies;

[0031] (3) Re-screening The bacterial strains obtaine...

Embodiment 2

[0057] In order to further enhance the industrial applicability of the protease liquid produced by the fermentation of Pseudomonas 3096-4, the present invention salts out and precipitates the fermented liquid, and after drying, dissolves it in a buffer solution to measure its anti-pilling effect. The specific operation method is to add 30% ammonium sulfate to the fermented enzyme solution of the monas 3096-4, place it at 4°C for 5-12 hours, centrifuge, remove the supernatant, freeze-dry, and set aside. When using, first use buffer (phosphate buffer or Tris-HCl buffer, pH 7.4-7.8), and dissolve to 0.5% (w / v). To treat the woolen cloth, the bath ratio is 1:30, act at 30°C for 50 minutes, wash and dry after treatment, and the felt shrinkage rate is 4.2%.

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com