Acidic donut-shaped macroporous/mesoporous material, preparation method thereof, and application of acidic donut-shaped macroporous/mesoporous material in preparation of 2, 6-bis(imino)pyridine

A technology of mesoporous materials and doughnuts, applied in chemical instruments and methods, catalytic reactions, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of high reaction temperature, difficult separation of products, and complicated post-processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The second aspect of the present invention provides a method for preparing an acidic doughnut-shaped macroporous mesoporous material, wherein the method comprises:

[0036] (1) first contacting the triblock copolymer, N,N-dimethylformamide and hydrochloric acid aqueous solution to obtain a mixed solution;

[0037] (2) Carrying out the second contacting of the mixed solution with tetraethyl orthosilicate, after filtering, washing and drying, the original powder mesoporous material is obtained;

[0038] (3) roasting the raw powder mesoporous material to obtain a doughnut-shaped perforated mesoporous material;

[0039](4) performing thermal activation treatment on the donut-shaped perforated mesoporous material to obtain an activated donut-shaped macroporous mesoporous material;

[0040] (5) Under the protection of nitrogen, acidify the activated donut-shaped macroporous mesoporous material with acetic acid to obtain an acidic donut-shaped perforated mesoporous material. ...

Embodiment 1

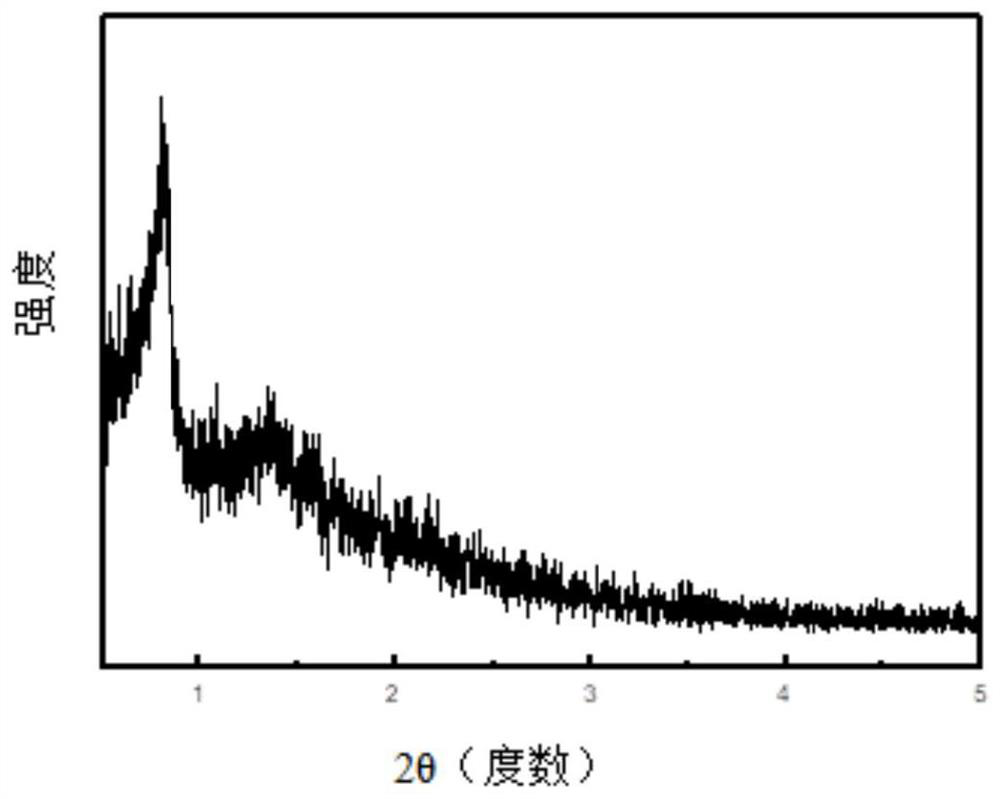

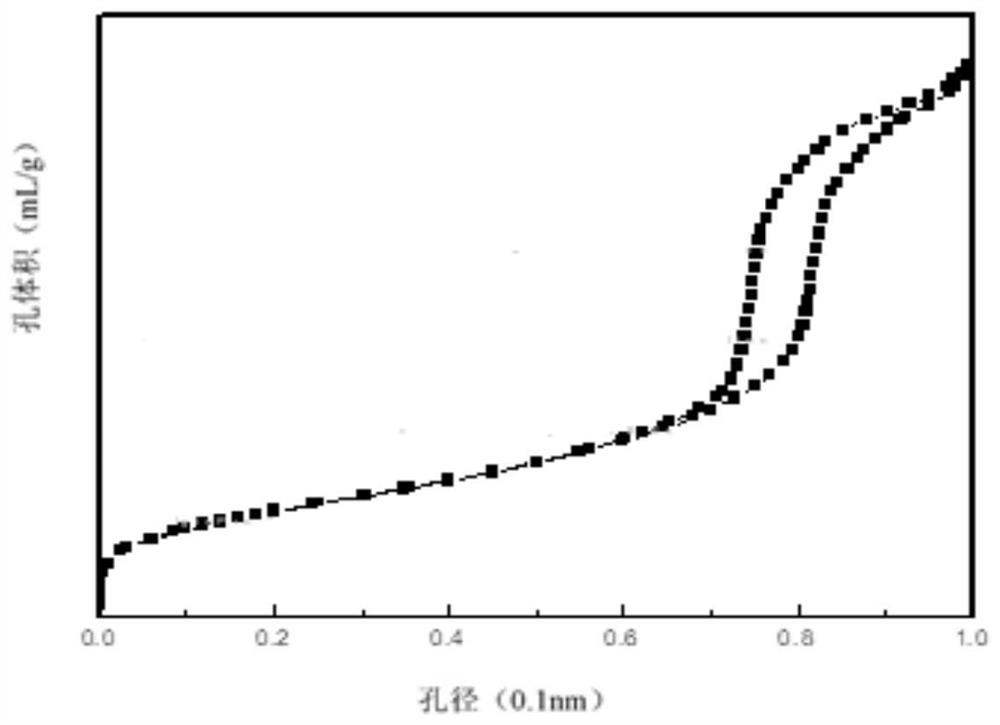

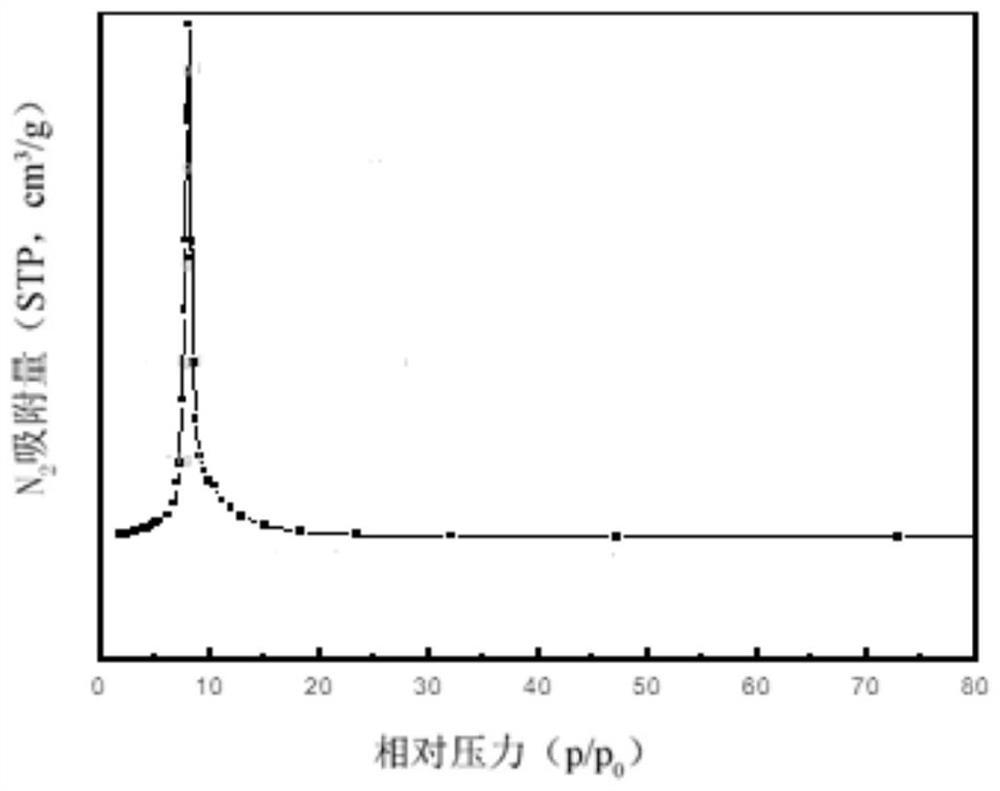

[0061] This example is to illustrate the acidic doughnut-shaped macroporous mesoporous material prepared by the method of the present invention.

[0062] (1) Add 2.0 g of P123 and 15 g of N,N-dimethylformamide (DMF) into a solution of 11.2 g of 37% hydrochloric acid and 64 mL of water, and stir at 40°C until P123 is completely dissolved;

[0063] (2) Add 4.45 grams of ethyl orthosilicate to the above solution and stir at 40°C for 24 hours;

[0064] (3) Obtain the original powder mesoporous material after filtering, washing and drying;

[0065] (4) Calcining the raw powder mesoporous material in a muffle furnace at 600°C for 24 hours to remove the template agent to obtain a donut-shaped mesoporous material;

[0066] (5) calcining the doughnut-shaped macroporous mesoporous material under nitrogen protection at 400°C for 10 h (thermal activation), removing hydroxyl groups and residual moisture, and obtaining the donut-shaped macroporous mesoporous material after thermal activati...

Embodiment 2-5

[0075] Prepare acidic donut-shaped macroporous mesoporous material according to the same method as in Example 1, the difference is: the consumption of the triblock copolymer, ethyl tetrasilicate and acetic acid is different, specifically as shown in Table 1, Table 1 is the preparation conditions; and the specific surface area, pore volume, most probable pore diameter and acetic acid content of the prepared mesoporous materials are different, as shown in Table 1, and Table 2 is the MBQ pore structure of donut-shaped macroporous mesoporous materials parameter.

[0076] Table 1

[0077] sample Dosage of P123 (g) P123, ethyl orthosilicate and acetic acid weight ratio Example 1 2.0 1:2.25:0.945 Example 2 2.0 1:2:0.75 Example 3 2.0 1:3:1.33 Example 4 2.0 1:1:0.22 Example 5 2.0 1:2:2

[0078] Table 2

[0079]

[0080]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com