Discharging mechanism of blood collection tube conveying line

A technology for blood collection tubes and conveyor lines, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., and can solve the problems of slow feeding of blood collection tubes, increased workload of medical staff, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

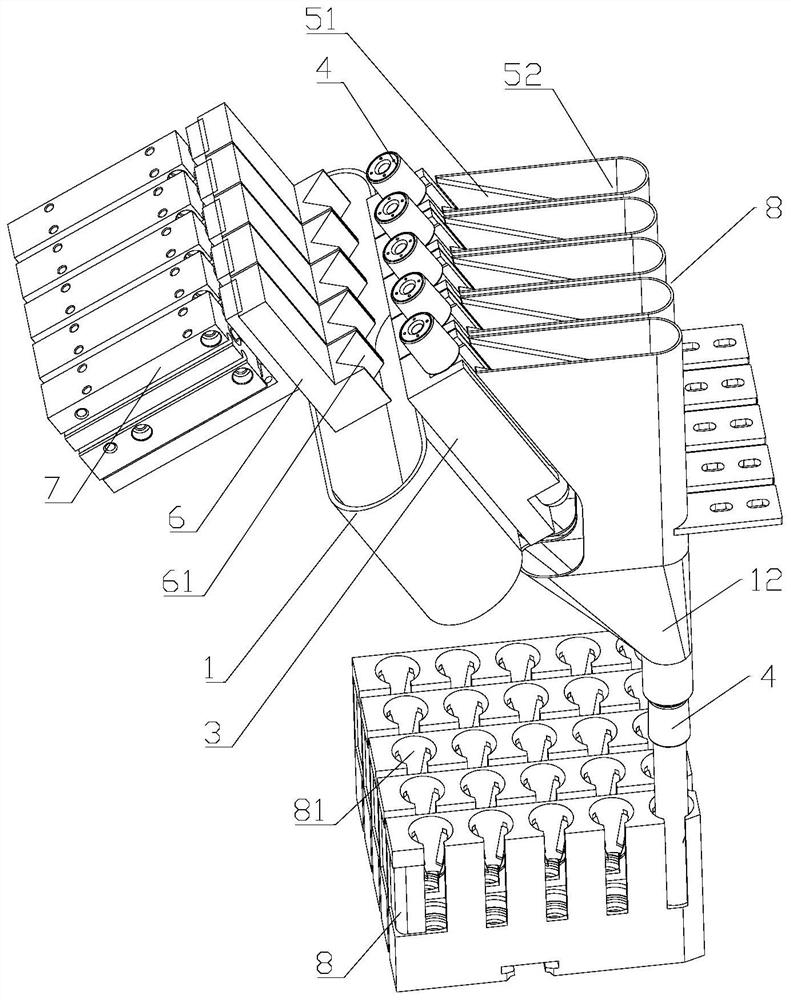

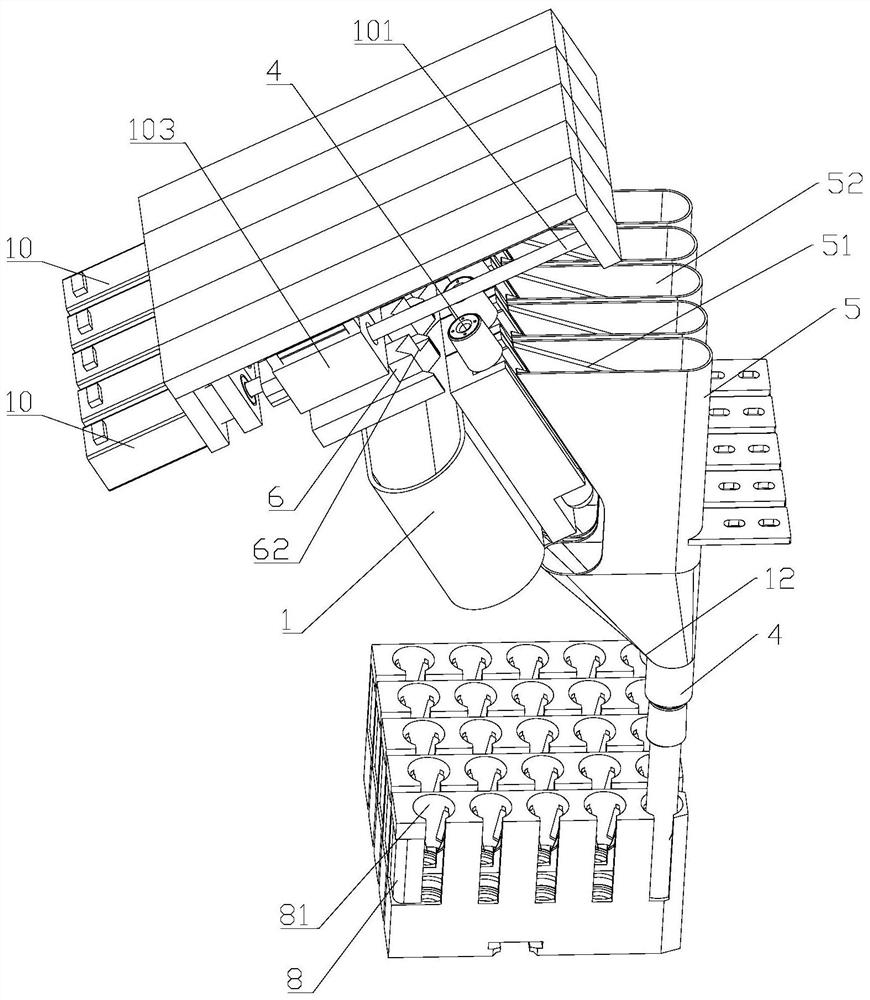

[0036] According to another specific embodiment of the present invention, the driving mechanism includes a stepping motor 10, a screw rod 101, and a moving nut 102; the power output end of the stepping motor 10 is fixedly connected to one end of the screw rod 101, and the moving nut 102 is sleeved on the screw rod 101 And be fixedly connected with pushing block 6. Such as figure 2 As shown, in the present embodiment, the power output end of the stepper motor 10 drives a screw 101 to rotate, thereby driving the moving nut 102 to move back and forth along the screw 101. Since the moving nut 102 is fixed to the push block 6, the push block 6 follows The blood collection tube 4 on the jig 3 is pushed back and forth back and forth by the moving nut 102 to accurately slide into the guide groove 52 .

[0037] According to another specific embodiment of the present invention, a second groove 62 is provided on an end surface of the push block 6 close to the blood collection tube 4 . ...

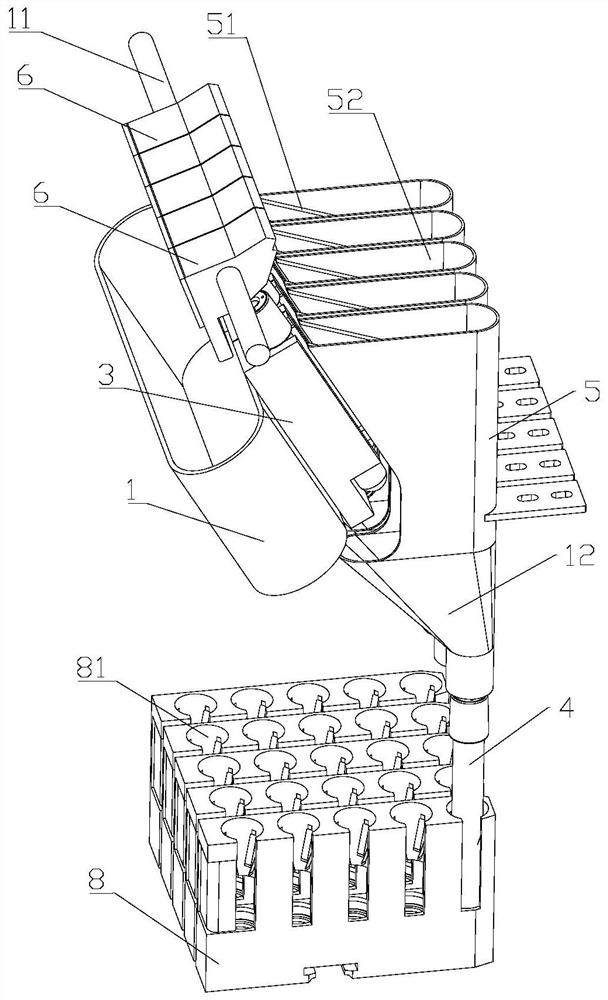

specific Embodiment approach

[0038] According to another specific embodiment of the present invention, the driving mechanism includes a toggle motor and a toggle shaft 11, the toggle shaft 11 and the toggle motor are located outside the clamping opening, the push block 6 is fixed on the toggle shaft 11, and the toggle One end of the shaft 11 is fixedly connected with the power output end of the toggle motor. Such as image 3 As shown, the toggle motor (not shown in the accompanying drawings) can be selected from various types of motors, such as asynchronous motors, etc., the power output end of the toggle motor drives the toggle shaft 11 to rotate, and the toggle shaft 11 passes through the opening of the push block 6 One end is fixedly connected with it, so the push block 6 is driven to move the blood collection tube 4 on the jig 3 to advance and slide into the guide groove 52 during the rotation of the toggle shaft 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com