Anti-static powder coating and preparation method thereof

A powder coating and anti-static technology, applied in powder coatings, conductive coatings, polyester coatings, etc., can solve the problems of poor filler acceptance, lower anti-static performance of coatings, and insufficient dispersion of anti-static powder coating raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

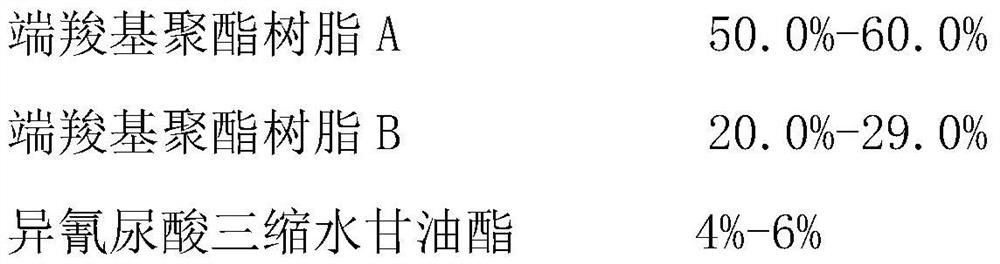

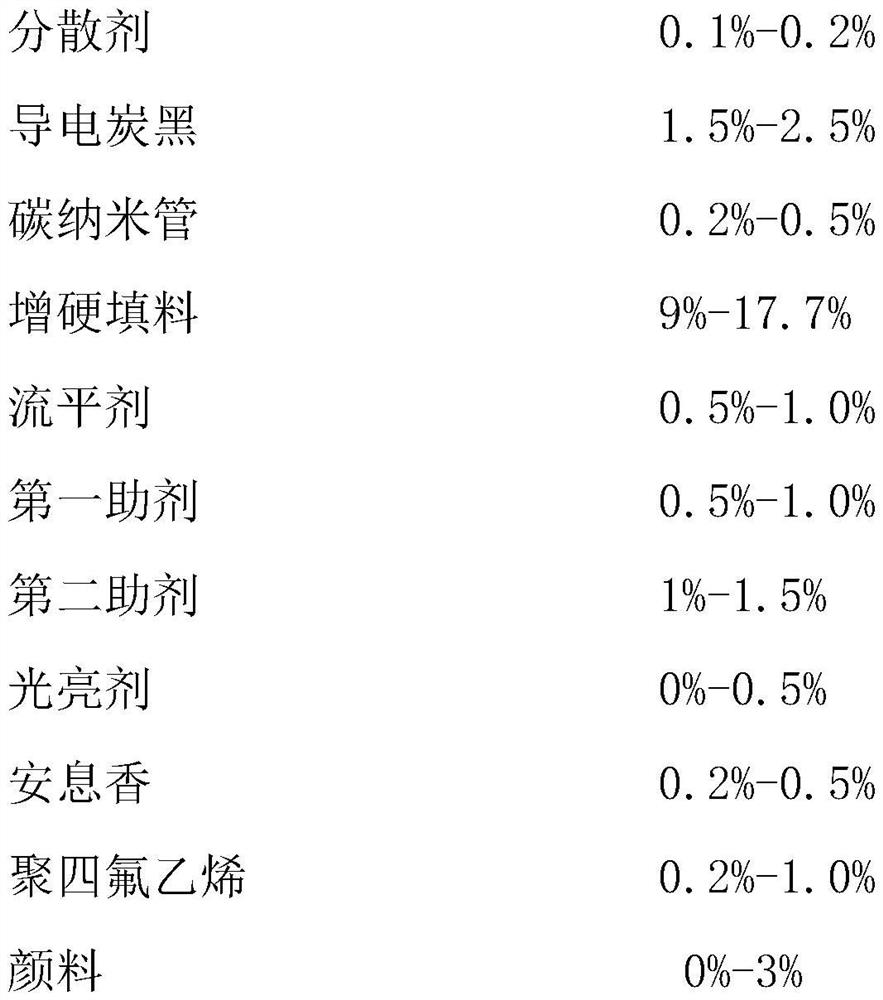

[0044] In one of the embodiments, a kind of preparation method of described antistatic powder coating is also provided, and described method comprises the following steps:

[0045]Put the hardening filler in the mixing kettle, then add the second additive, and after it is fully mixed, place it in a water bath at a temperature of 65°C-85°C, shake it for 8min-15min, and then extrude it under the pressure of 45MPa-55MPa processing, and finally obtain the mixture A through the first crushing treatment;

[0046] Continue to add carboxyl-terminated polyester resin A, carboxyl-terminated polyester resin B, triglycidyl isocyanurate, dispersant, conductive carbon black, carbon nanotubes, hardening filler, leveling agent, 1. Auxiliaries, brighteners, benzoin, polytetrafluoroethylene and pigments are fully mixed to obtain mixture B;

[0047] The mixture B is subjected to melt extrusion treatment, second crushing treatment and milling treatment to obtain an antistatic powder coating.

...

Embodiment 6-8

[0087] A kind of preparation method of antistatic powder coating in embodiment 6-8, comprises the following steps:

[0088] The modified wax and the carboxylic acid derivative are placed in a mixing tank, and stirred at a stirring speed of 1000r / min for 15min to obtain a uniformly dispersed second additive;

[0089] Put the hardening filler in the mixing kettle, then add the second additive, and after it is fully mixed, place it in a water bath at 65°C, vibrate for 15 minutes, then extrude it at 45MPa and 85°C, and finally Mixture A is obtained through the first crushing treatment;

[0090] Continue to add carboxyl-terminated polyester resin A, carboxyl-terminated polyester resin B, triglycidyl isocyanurate, dispersant, conductive carbon black, carbon nanotubes, hardening filler, leveling agent, 1. Auxiliaries, brighteners, benzoin, polytetrafluoroethylene and pigments are fully mixed to obtain mixture B;

[0091] The mixture B is melt-extruded, and the process parameters of...

Embodiment 9-11

[0103] 20g of modified wax and 3g of acetic anhydride were placed in a mixing tank, and stirred at a stirring speed of 800r / min for 15min to obtain a uniformly dispersed second additive;

[0104] Put the hardening filler in the mixing kettle, then add the second additive, and after it is fully mixed, place it in a water bath at a temperature of 75°C. After vibrating for 10 minutes, extrude it at 50MPa and a temperature of 75°C, and finally Obtain mixture A through the first crushing treatment;

[0105] Continue to add carboxyl-terminated polyester resin A, carboxyl-terminated polyester resin B, triglycidyl isocyanurate, dispersant, conductive carbon black, carbon nanotubes, hardening filler, leveling agent, 1. Auxiliaries, brighteners, benzoin, polytetrafluoroethylene and pigments are fully mixed to obtain mixture B;

[0106] The mixture B is melted and extruded at a speed of 1800r / min-3000r / min, and an antistatic powder coating with a particle size of 20 μm is obtained after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com