Marine gear box

A gearbox and marine technology, which is applied in the direction of gear transmission, gear lubrication/cooling, belt/chain/gear, etc. It can solve the problems of troublesome manufacturing and installation of gearboxes, easy damage, oil leakage, and low lubricating oil pressure. Beautiful appearance, reduced pipeline connections, and the effect of reducing excessive parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

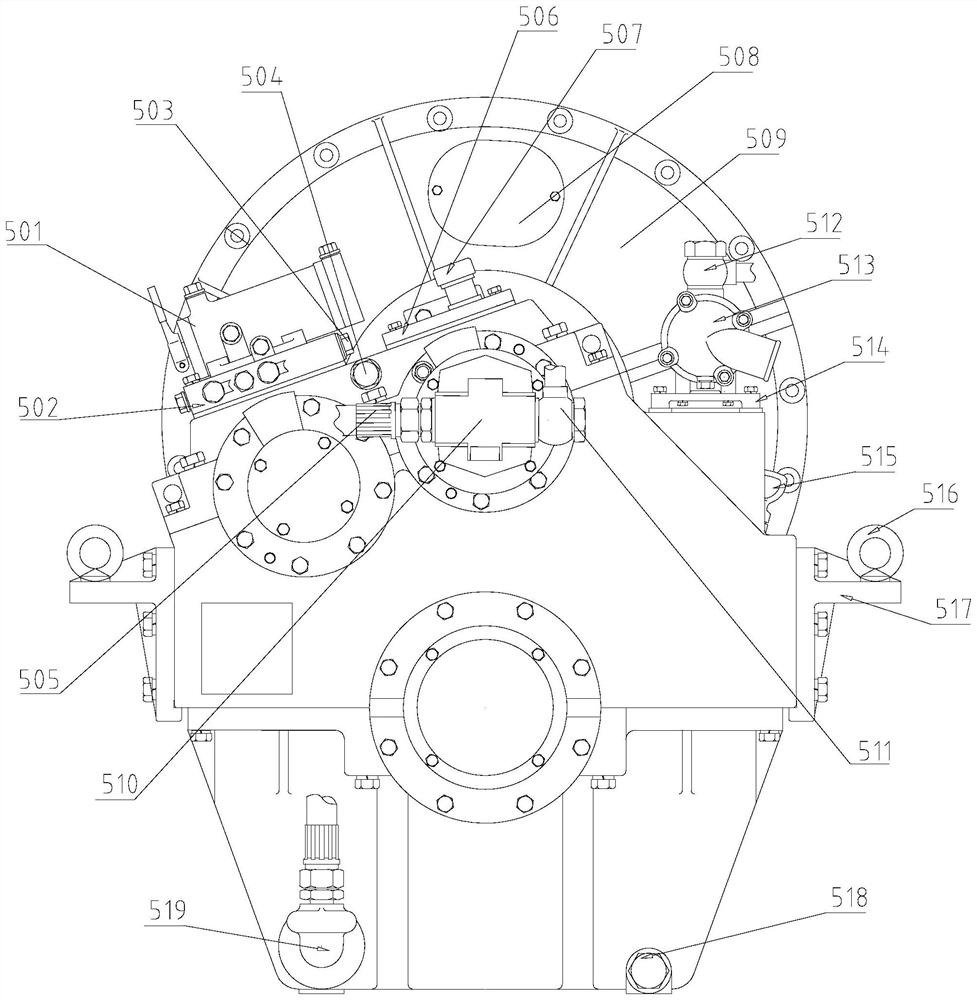

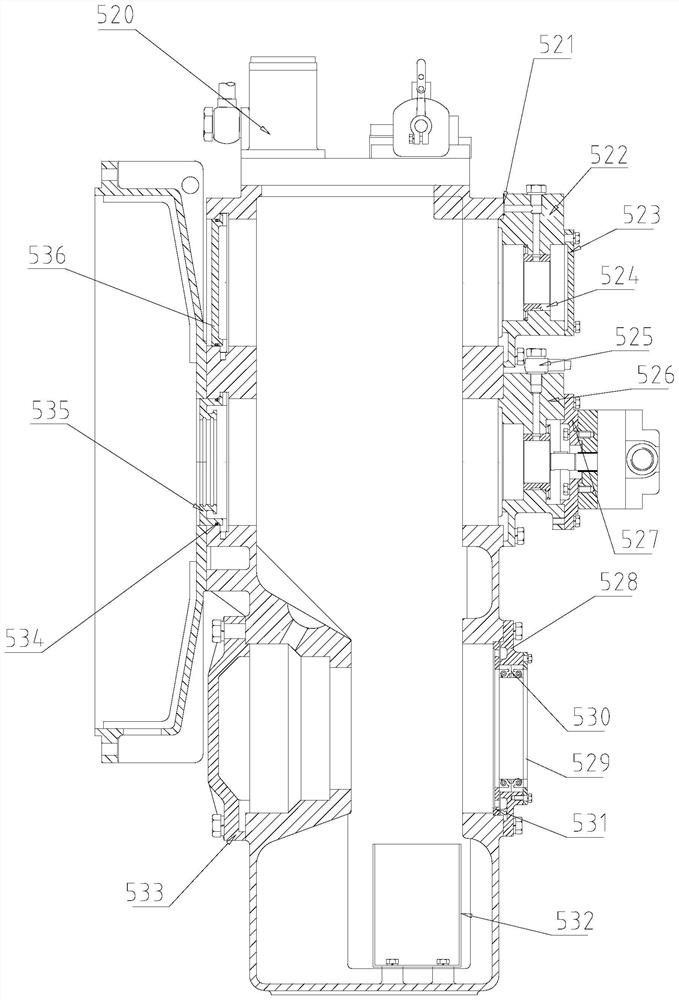

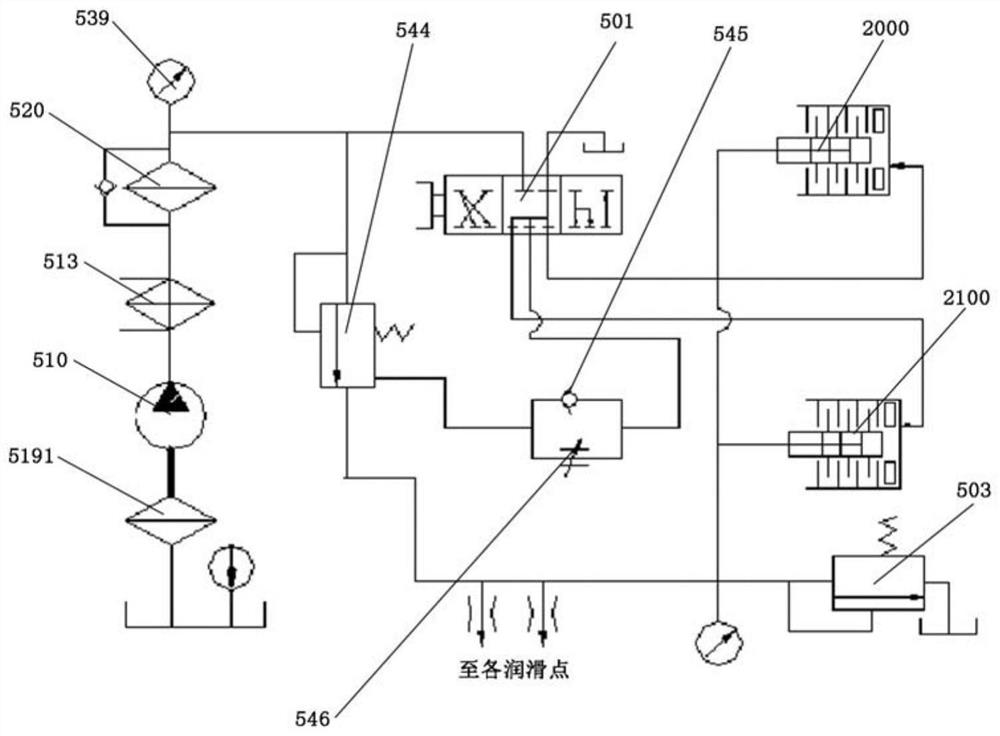

[0048] Such as Figure 1 to Figure 4 A marine gearbox shown includes a housing, an input shaft part 20, a transmission shaft part 30, an output shaft assembly 40 and a control system part 50, and the input shaft part 20, the transmission shaft part 30, and the output shaft assembly 40 are all The input shaft part 20 is also connected with a high elastic coupling 10 or a rubber toothed sleeve coupling through bearings arranged in the housing and through gear transmission.

[0049] The input shaft component 20 includes an input shaft 201 and a coupling 203, a right-handed transmission gear 204, a clutch assembly, and a drive gear assembly 202 that are sequentially arranged on the input shaft 201. The coupling 203 is conical with the input shaft 201. Interference connection, the right-handed transmission gear 204 is shrink-fit connected with the input shaft 201...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com