Method for detecting nitrofuran veterinary drugs in shrimp flesh

A technology of nitrofuran and detection method, which can be applied to measurement devices, instruments, scientific instruments, etc., can solve the problems of cumbersome and complicated detection process, shortened derivatization time, and low detection efficiency, and achieves the advantages of shortened time, rapid response and high sensitivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

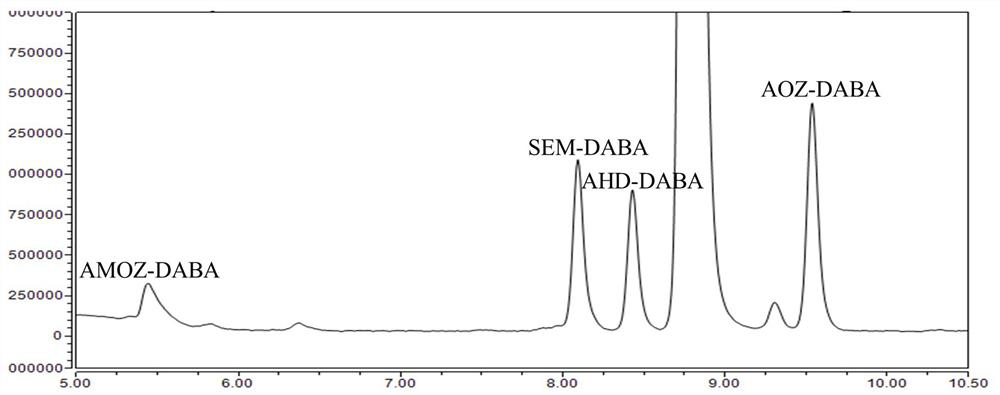

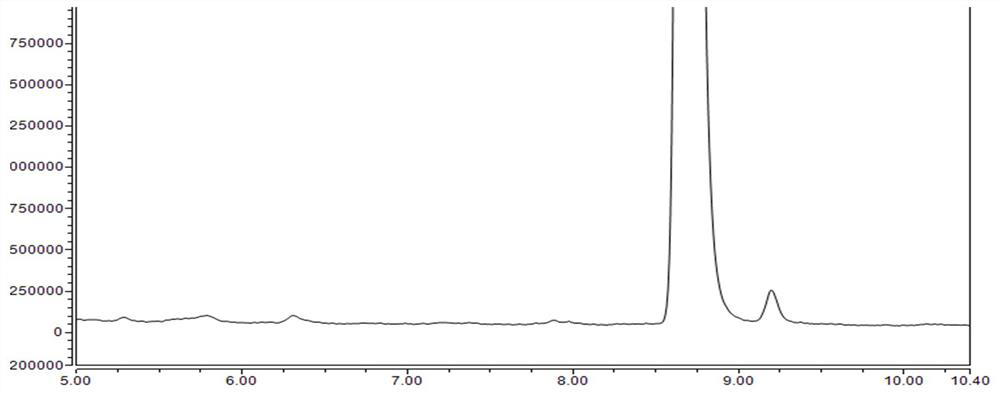

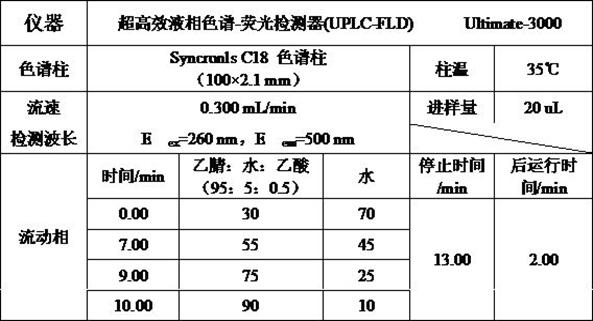

Image

Examples

Embodiment 1

[0041] Weigh 2.00 g of homogeneous shrimp meat sample into a 50 mL centrifuge tube, add 10 mL of 0.2 mol / L HCl, vortex for 2 min, place the sample in a constant temperature ultrasonic reactor at 40 °C for 20 min, and then Centrifuge at 6000 r / min for 5 min, remove 5 mL of supernatant, and concentrate the supernatant at 50 °C under nitrogen protection.

[0042] Add 50 uL of 8 mmol / L 4-dianilinobenzaldehyde, 200 uL of acetonitrile and 200 uL of aqueous hydrochloric acid at pH=1.0 to the concentrated solution in sequence, vortex for 2 min, and place the mixed reaction solution at 50 °C Derivatize and mark in a constant temperature ultrasonic reactor for 20 min. After derivatization, add 50 uL, 0.5 mol / L NaOH to neutralize the acidity and alkalinity of the reaction solution, and vortex for 1 min. Centrifuge at a high speed for 10 min, pipette the supernatant to pass through the membrane, and then test it on the machine.

Embodiment 2

[0044] Weigh 1.00 g of homogeneous shrimp meat sample into a 50 mL centrifuge tube, add 5 mL of 0.2 mol / L HCl, vortex for 2 min, place the sample in a constant temperature ultrasonic reactor at 40 °C for 20 min, and then Centrifuge at 6000 r / min for 5 min, remove all the supernatant, and concentrate the supernatant at 50°C under nitrogen protection.

[0045]Add 50 uL of 8 mmol / L 4-dianilinobenzaldehyde, 200 uL of acetonitrile and 200 uL of aqueous hydrochloric acid at pH=1.0 to the concentrated solution in sequence, vortex for 2 min, and place the mixed reaction solution at 50 °C Derivatize and mark in a constant temperature ultrasonic reactor for 20 min. After derivatization, add 50 uL, 0.5 mol / L NaOH to neutralize the acidity and alkalinity of the reaction solution, and vortex for 1 min. Centrifuge at a high speed for 10 min, pipette the supernatant to pass through the membrane, and then test it on the machine.

Embodiment 3

[0047] Weigh 2.00 g of homogeneous shrimp meat sample into a 50 mL centrifuge tube, add 10 mL of 0.2 mol / L HCl, vortex for 2 min, place the sample in a constant temperature ultrasonic reactor at 60 °C for 10 min, and then Centrifuge at 6000 r / min for 5 min, remove 5 mL of supernatant, and concentrate the supernatant at 60 °C under nitrogen protection.

[0048] Add 50 uL of 8 mmol / L 4-dianilinobenzaldehyde, 200 uL of acetonitrile and 200 uL of aqueous hydrochloric acid at pH=1.0 to the concentrated solution in sequence, vortex for 2 min, and place the mixed reaction solution at 50 °C Derivatize and mark in a constant temperature ultrasonic reactor for 20 min. After derivatization, add 50 uL, 0.5 mol / L NaOH to neutralize the acidity and alkalinity of the reaction solution, and vortex for 1 min. Centrifuge at a high speed for 10 min, pipette the supernatant to pass through the membrane, and then test it on the machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com