Boron-doped ferro-manganese magnetic biochar material as well as preparation method and application thereof

A boron-doped, biochar technology, applied in the preparation of boron-doped iron-manganese magnetic bio-char materials, and the field of boron-doped iron-manganese magnetic bio-char materials, can solve the problem of good reusability, poor organic removal effect, Good pollution effect, etc., to achieve strong reusability, good removal effect, and the effect of promoting removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

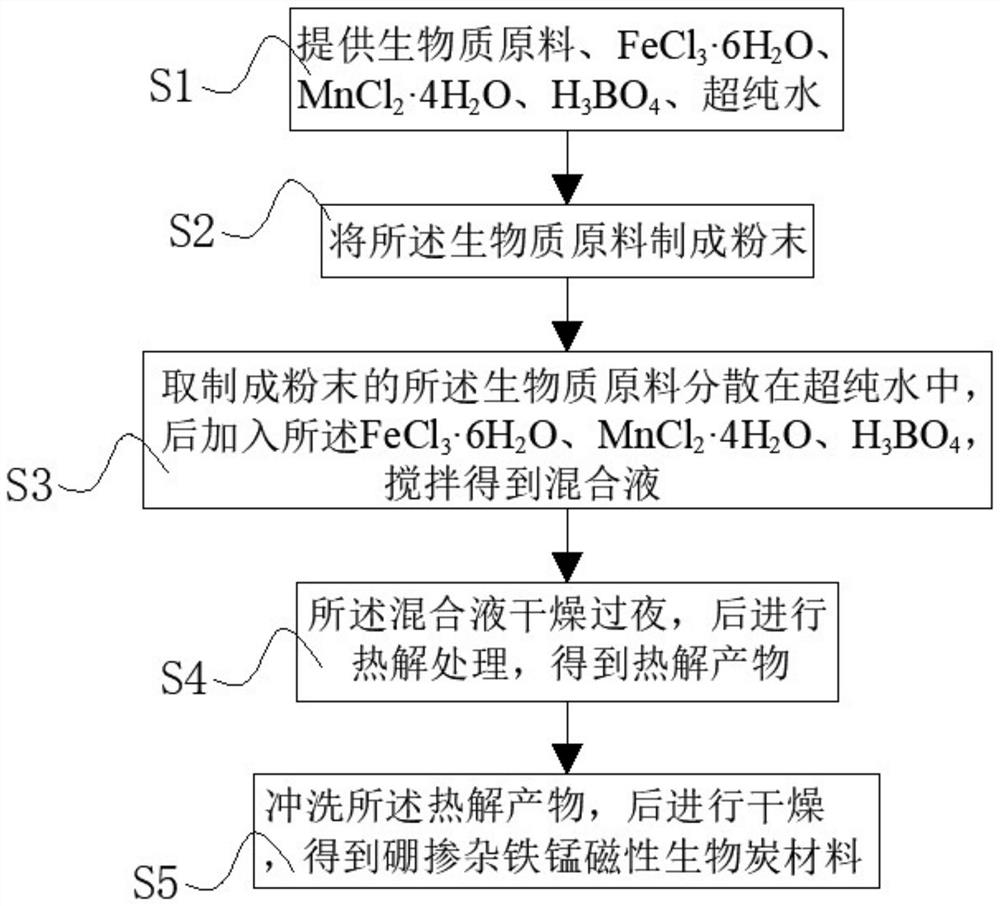

[0038] Please refer to figure 1 , this embodiment provides a method for preparing a boron-doped iron-manganese magnetic biochar material. The preparation method comprises the following steps:

[0039] S1 provides biomass raw materials, FeCl 3 ·6H 2 O, MnCl 2 4H 2 O, H3 BO 4 ,Ultra-pure water.

[0040] S2 making the biomass raw material into powder;

[0041] The biomass raw material is washed to remove impurities, and then placed in an oven with an operating temperature of 65° C. for drying. The dried biomass raw material is taken out and ground into powder.

[0042] S3 takes the biomass raw material made into powder and disperses it in ultrapure water, and then adds the FeCl 3 ·6H 2 O, MnCl 2 4H 2 O and H 3 BO 4 , stirring to obtain a mixed solution;

[0043] The FeCl 3 ·6H 2 O, MnCl 2 4H 2 O and H 3 BO 4 The addition process is carried out under the condition of strong magnetic field stirring. The FeCl 3 ·6H 2 O, MnCl 2 4H 2 O and H 3 BO 4 The ratio...

Embodiment 2

[0052] This embodiment provides a method for preparing a boron-doped ferromanganese magnetic biochar material, the preparation method comprising the following steps:

[0053] S1 provides agricultural waste rice husk, FeCl 3 ·6H 2 O, MnCl 2 4H 2 O, H 3 BO 4 ,Ultra-pure water;

[0054] In this embodiment, the use of agricultural waste rice husk as a biomass raw material is used as an example for illustration. In other embodiments, peanut shells, grapefruit peels, and traditional Chinese medicine waste residues can also be used as biomass raw materials to prepare magnetic biochar materials.

[0055] The agricultural waste rice husks described in S2 are washed to remove impurities, and then dried in an oven with an operating temperature of 65° C., and the dried agricultural waste rice husks are taken out and ground into powder.

[0056] S3 Disperse 5g of powdered agricultural waste rice husk in 90ml of ultrapure water, add 16.22g of FeCl under strong magnetic field stirring...

Embodiment 3

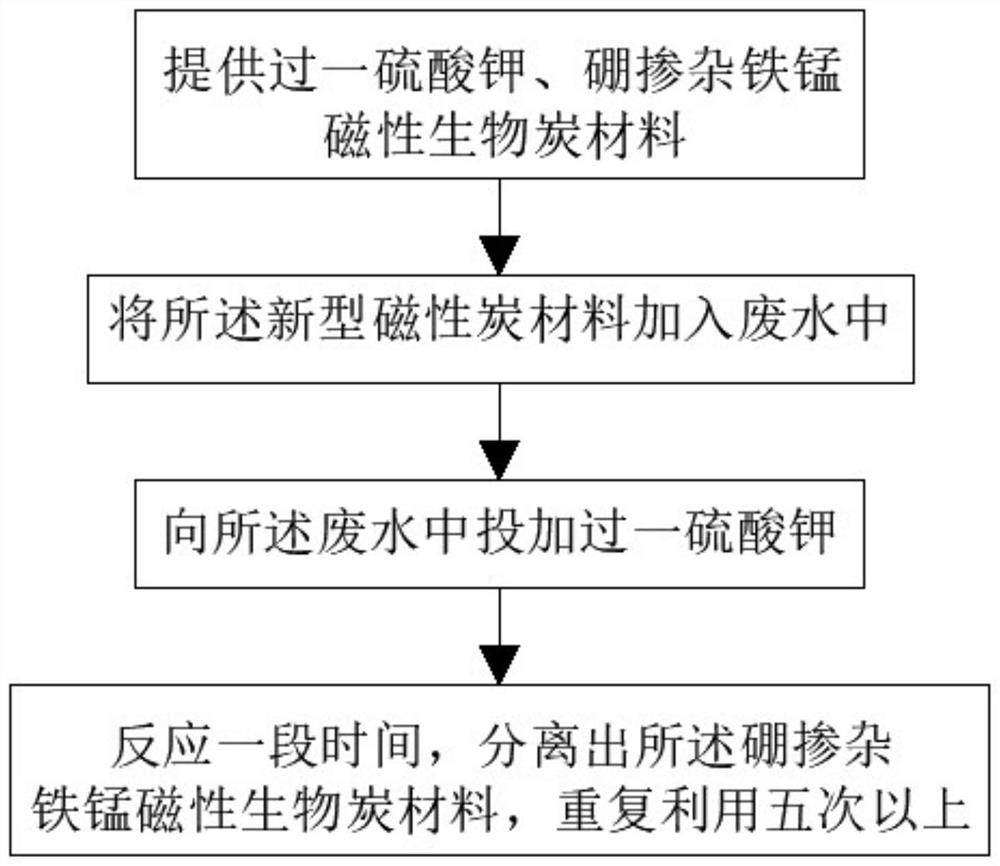

[0061] This embodiment provides a boron-doped ferromanganese magnetic biochar material, which is used to remove organic matter in the water environment, and the boron-doped ferromanganese magnetic biochar material is as described in embodiment 1 or embodiment 2. The preparation method of the boron-doped iron-manganese magnetic biochar material is prepared. The boron-doped ferromanganese magnetic biochar material has the following components: biomass raw material, FeCl 3 ·6H 2 O, MnCl 2 4H 2 O and H 3 BO 4 The boron-doped iron-manganese magnetic biochar material is produced in proportion. Among them, the biomass raw material, FeCl 3 ·6H 2 O, MnCl 2 4H 2 O and H 3 BO 4 The weight ratio is 5:16.22:5.94:1.

[0062] The composition of the boron-doped iron-manganese magnetic biochar material in parts by weight is as follows: 5g of biomass raw material, FeCl 3 ·6H 2 O16.22g, MnCl 2 4H 2 O 5.94g, H 3 BO 4 1g. In the present embodiment, take 5g biomass raw material,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com