Preparation method of bismuth oxide composite visible light catalytic material loaded with CdS quantum dots and product prepared by preparation method

A catalytic material, bismuth oxide technology, applied in the field of photocatalytic materials, can solve the problems of poor photoresponse and limitations, and achieve the effects of good dispersion, uniform particles and high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this embodiment, a method for preparing a bismuth oxide composite visible light catalytic material loaded with CdS quantum dots, the steps are as follows:

[0024] (1) Synthesis of Bi with Bi-MOF as precursor 2 o 3

[0025] (1-1) 0.45gBi(NO 3 ) 3 ·5H 2 O and 2.25g trimesic acid (H 3 BTC) is dissolved in the DMF solution of 180mL methanol (according to the volume ratio DMF: methanol=4: 1), after magnetic stirring 30min, obtain mixed solution;

[0026] (1-2) Transfer the above mixed solution into a reaction kettle and react at 120°C for 24 hours. After the reaction product is cooled, wash it with DMF and methanol for 3 times, and then put it in a vacuum oven at 60°C. Dry for 10 hours to obtain a white Bi-MOF precursor;

[0027] (1-3) Put the above-mentioned Bi-MOF precursor in a muffle furnace, and calcinate it at 500°C for 2 hours in an air atmosphere to obtain light yellow Bi 2 o 3 product;

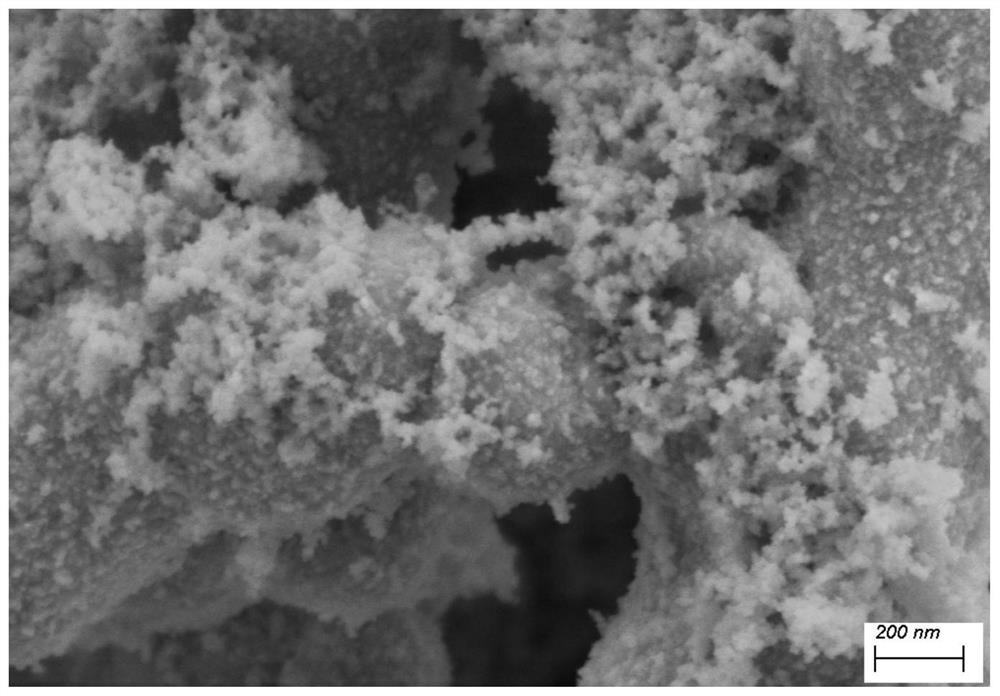

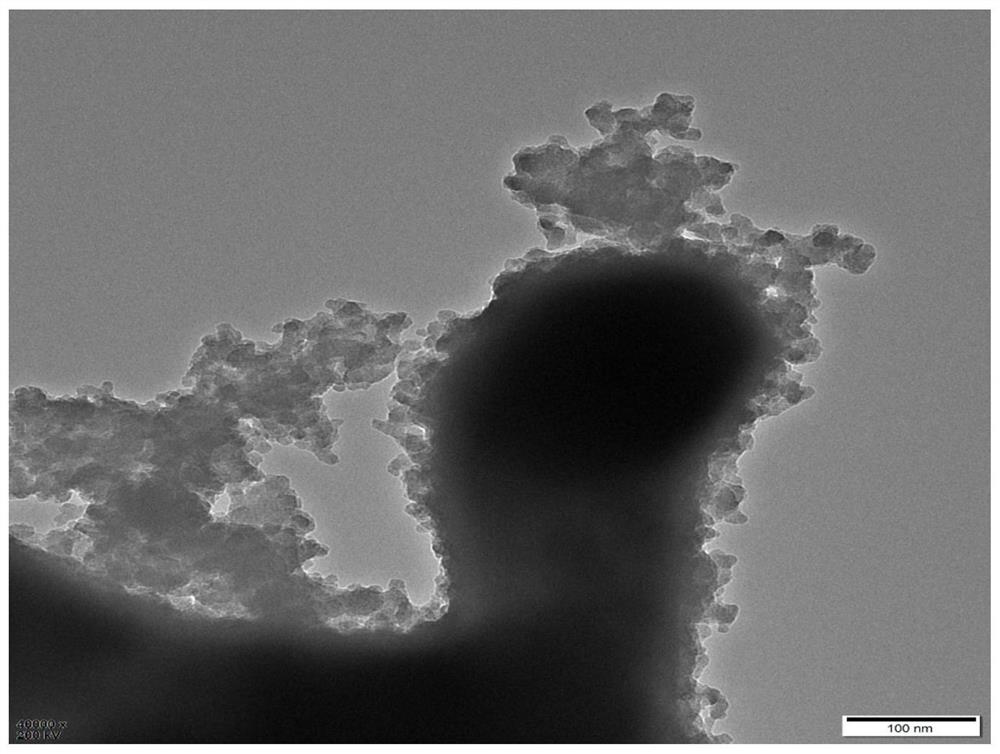

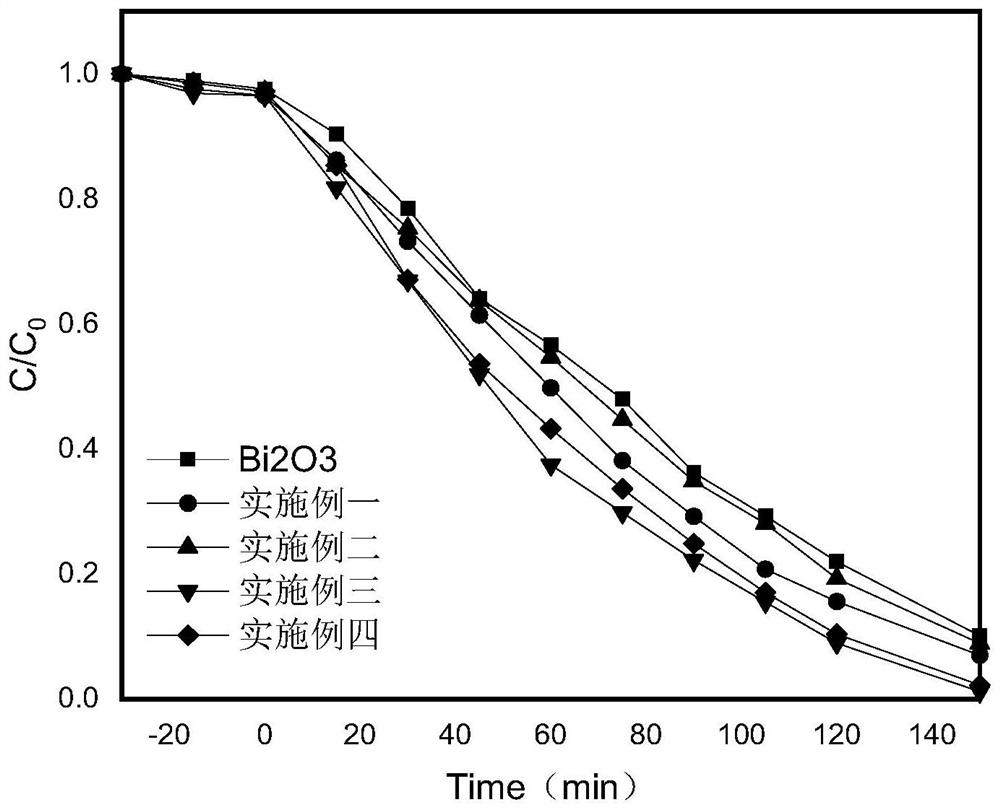

[0028] (2)CdS@Bi 2 o 3 Preparation of Composite Visible Light C...

Embodiment 2

[0031] In this embodiment, a method for preparing a bismuth oxide composite visible light catalytic material loaded with CdS quantum dots, the steps are as follows:

[0032] (1) Synthesis of Bi with Bi-MOF as precursor 2 o 3

[0033] (1-1) 0.45gBi(NO 3 ) 3 ·5H 2 O and 2.25g trimesic acid (H 3 BTC) is dissolved in the DMF solution of 180mL methanol (according to the volume ratio DMF: methanol=4: 1), after magnetic stirring 30min, obtain mixed solution;

[0034] (1-2) Transfer the above mixed solution into a reaction kettle and react at 130°C for 20 hours. After the reaction product is cooled, wash it with DMF and methanol for 3 times, and then put it in a vacuum oven at 60°C. Dry for 10 hours to obtain a white Bi-MOF precursor;

[0035] (1-3) Put the above-mentioned Bi-MOF precursor in a muffle furnace and calcinate it at 520°C for 2 hours in an air atmosphere to obtain light yellow Bi 2 o 3 product;

[0036] (2)CdS@Bi 2 o 3 Preparation of Composite Visible Light Ca...

Embodiment 3

[0039] In this embodiment, a method for preparing a bismuth oxide composite visible light catalytic material loaded with CdS quantum dots, the steps are as follows:

[0040] (1) Synthesis of Bi with Bi-MOF as precursor 2 o 3

[0041] (1-1) 0.45gBi(NO 3 ) 3 ·5H 2 O and 2.25g trimesic acid (H 3 BTC) is dissolved in the DMF solution of 180mL methanol (according to the volume ratio DMF: methanol=4: 1), after magnetic stirring 30min, obtain mixed solution;

[0042] (1-2) Transfer the above mixed solution into a reaction kettle and react at 140°C for 12 hours. After the reaction product is cooled, it is washed with DMF and methanol for 3 times, and then placed in a vacuum oven at 60°C. Dry for 10 hours to obtain a white Bi-MOF precursor;

[0043] (1-3) Put the above-mentioned Bi-MOF precursor in a muffle furnace, and calcinate it at 550°C for 2 hours in an air atmosphere to obtain light yellow Bi 2 o 3 product;

[0044] (2)CdS@Bi 2 o 3 Preparation of Composite Visible Ligh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com