Machining method and welding method of steel blank with aluminum-silicon coating

A processing method and welding method technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of difficult control and low weld bead strength, achieve stable welding process, improve weld bead shape, and improve toughness and the effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

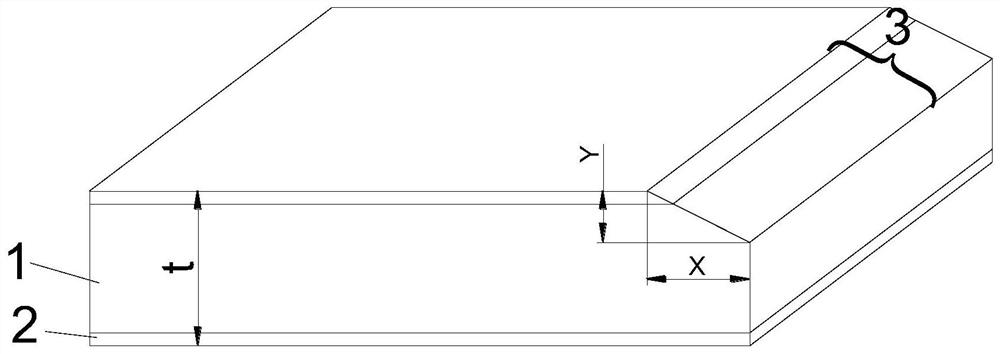

[0050] When the part to be welded is the edge of the blank, the substrate 1 and the pre-coating layer 2 are removed by milling or planing to form a groove structure 3, such as figure 1 As shown, the width X of the groove structure 3 is 0.2-2.3 mm, and the height Y of the groove structure 3 is 0.1 mm-0.7 times the thickness of the blank.

no. 2 example

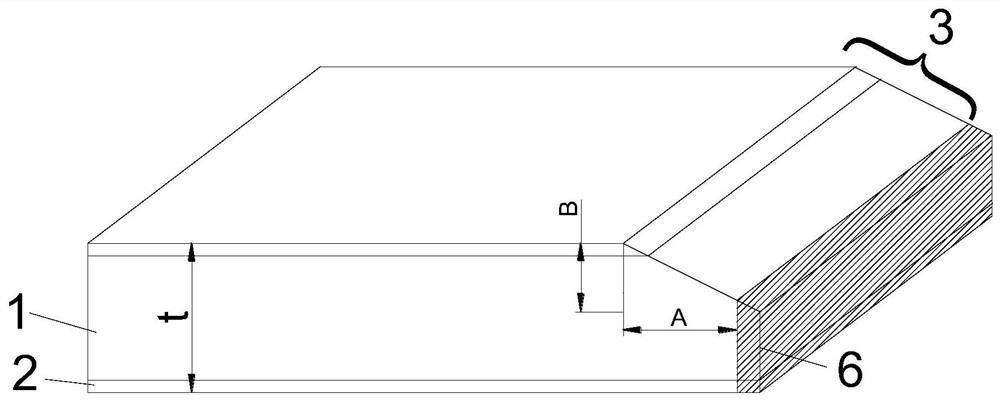

[0052] When the part to be welded is the edge of the blank, the substrate and the pre-coating layer are removed from the part to be welded of the blank to form an initial groove structure, the width of the initial groove structure is 0.3-4mm, and the initial groove structure The height is 0.2mm-0.9 times the thickness of the blank.

[0053] Cutting the initial groove structure according to a plane 6 to obtain a groove structure 3, the width of the groove structure 3 is 0.2mm-2.3mm, and the height of the groove structure 3 is 0.1mm-0.7 times the thickness of the blank.

no. 3 example

[0055] When the part to be welded is the upper middle part of the blank, step S1 specifically includes:

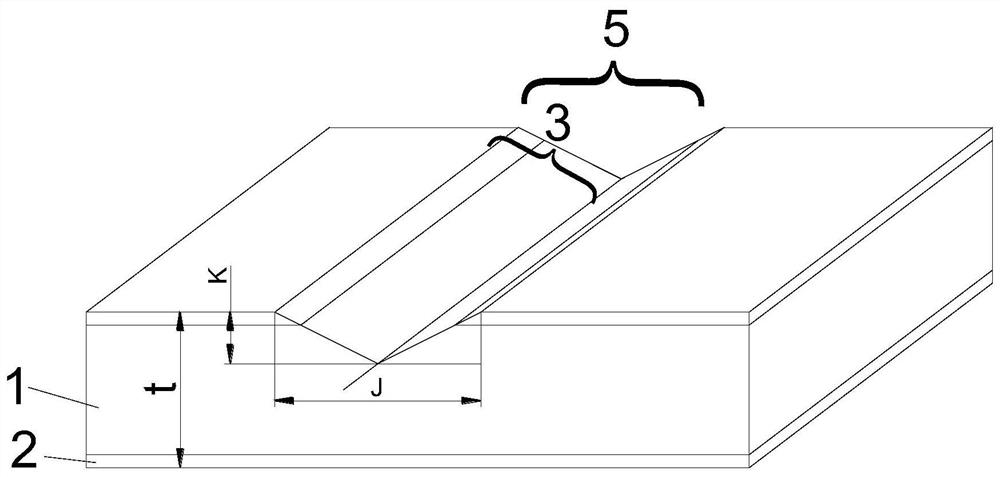

[0056] The removal of the substrate 1 and said pre-coating 2 of the part of the blank to be welded forms a notch structure 5, the person skilled in the art knows how to adapt different specific parameters to the removal operation in order to achieve as complete and rapid removal of part of the substrate as possible And pre-coating, the parameters such as the choice of planing blade type, relative translational speed, pressure. For example, a planer installed on an axis can be used, and the planer is driven to translate in a straight line parallel to the surface of the board to form a notch structure 5 on the surface of the board, such as image 3 shown;

[0057] Cut the blank into two sections from the central axis position of the notch structure 5. Laser shock cutting can be used to cut along a straight line in the middle of the notch, so that the edge of each section of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com