Preparation method of polyamide 6 and polyamide 6

A polyamide and amide exchange technology, applied in the polyamide field, can solve the problems of long preparation process time, unstable product quality, and low production efficiency, and achieve stable control of process parameters, small product batch differences, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

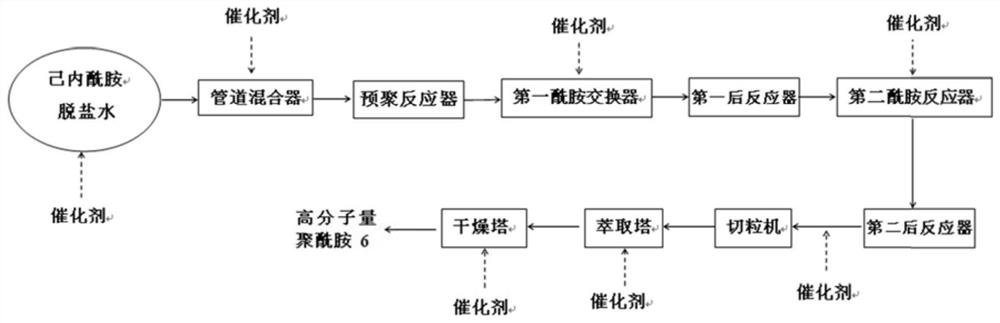

Method used

Image

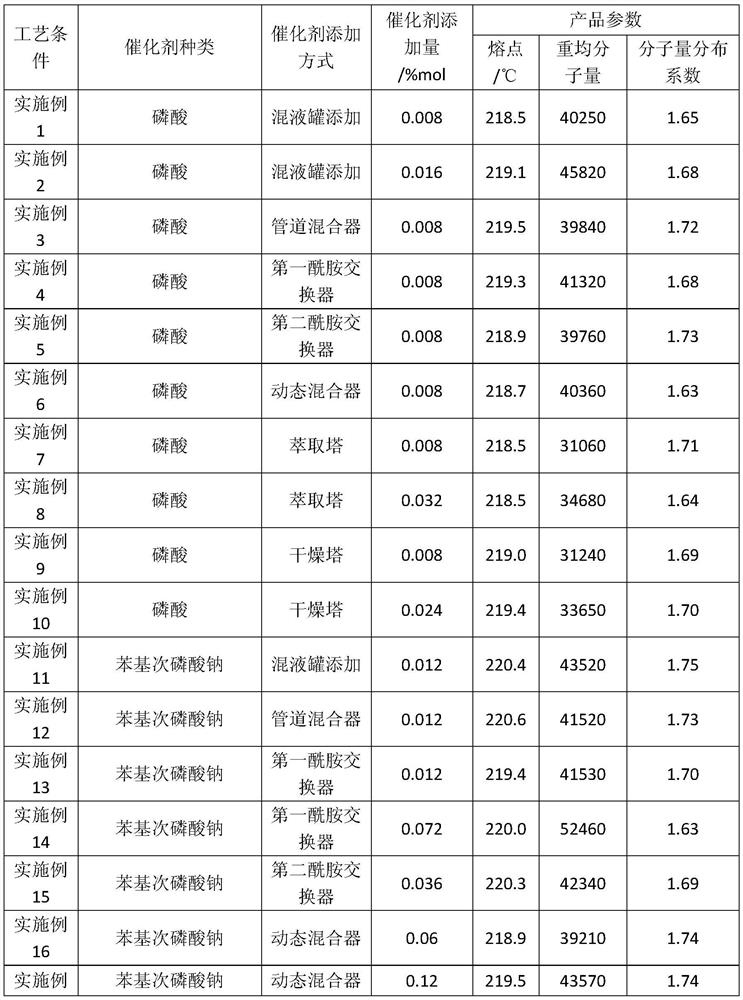

Examples

Embodiment 1

[0045] In this embodiment, polyamide 6 is prepared by the following method:

[0046] a. 540kg of fresh molten caprolactam, 10.8kg of desalted water, and 0.008% mol phosphoric acid (relative to the amount of the total substance of caprolactam) are continuously added into the mixed liquid tank every hour to obtain a mixture.

[0047] b. Mix the mixture continuously in the pipeline mixer, and then enter the prepolymerization reactor to polymerize to form a prepolymer. The pressure of the prepolymerization reactor is 15 barg, the temperature is 262°C, and the residence time is 3h.

[0048] c. The prepolymer in the prepolymerization reactor is continuously sent to the first amide exchanger, the temperature of the first amide exchanger is 260° C., the residence time is 0.5 h, and the pressure drops from 15 barg to 4 barg.

[0049] d. The material of the first amide exchanger is continuously sent to the first post-reactor, the temperature of the first post-reactor is 260°C, the react...

Embodiment 46

[0057] In this example, polyamide 6 was prepared by the following method:

[0058] a. 3500kg fresh molten caprolactam, 1350kg caprolactam concentrated solution (concentration is wt.69%), 0.06% mol phenyl hypophosphite (relative to the amount of the total substance of caprolactam) are continuously added in the mixed liquid tank per hour to obtain a mixture.

[0059] b. Continuously mix the mixture in a static mixer, and then enter a prepolymerization reactor to polymerize to form a prepolymer. The pressure of the prepolymerization reactor is 25 barg, the temperature is 263°C, and the residence time is 2h.

[0060] c. Send the prepolymer in the prepolymerization reactor to the first amide exchanger, the temperature of the first amide exchanger is 270° C., the residence time is 1.5 h, and the pressure drops from 25 barg to 5 barg.

[0061] d. Send the material of the first amide exchanger to the first post-reactor, the temperature of the first post-reactor is 258° C., the reactio...

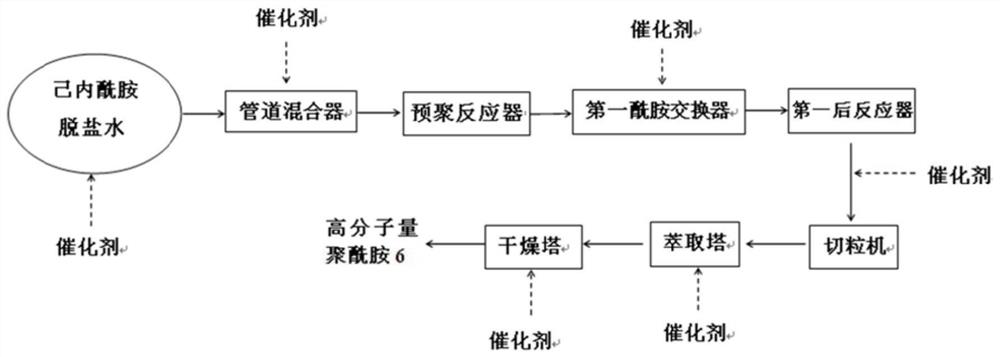

Embodiment 55

[0066] In this example, the attached figure 2 The shown route prepares polyamide 6:

[0067] a. 540kg of fresh molten caprolactam, 10.8kg of desalted water, and 0.008% mol phosphoric acid (relative to the amount of the total substance of caprolactam) are continuously added into the mixed liquid tank every hour to obtain a mixture.

[0068] b. Mix the mixture in the pipeline mixer, and then enter the prepolymerization reactor to polymerize to form a prepolymer. The pressure of the prepolymerization reactor is 10 barg, the temperature is 262°C, and the residence time is 3h.

[0069] c. The prepolymer in the prepolymerization reactor is continuously sent to the first amide exchanger, the temperature of the first amide exchanger is 260° C., the residence time is 0.5 h, and the pressure drops from 10 barg to 4 barg.

[0070] d. Send the material of the first amide exchanger to the first post-reactor, the temperature of the first post-reactor is 240° C., the reaction pressure drop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com