Integrated energy-saving dehumidifying and heating device

A technology for heating devices and surface coolers, which is applied in the fields of food equipment, medicine, chemical industry, and materials. It can solve problems such as unstable control of process parameters, increased maintenance costs, and increased time costs, and achieves stable control of process parameters and high production efficiency. The effect of cost reduction and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

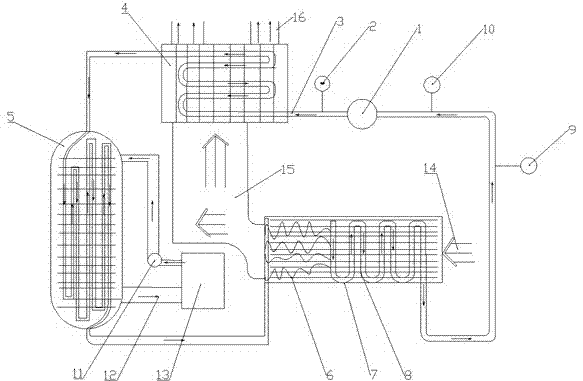

[0021] combined with figure 1 According to an integrated energy-saving dehumidification heating device of the present invention, it consists of 1-compressor, 2-high pressure gauge, 3-freon pipeline, 4-air-cooled surface cooler, 5-volute tube type surface cooler, 6- Capillary tube, 7-air-cooled air box, 8-evaporator, 9-oil and gas separator, 10-low pressure gauge, 11-water tower water pump, 12-water tower circulating water pipe, 13-water tower, 14-normal temperature and humidity air, 15-air duct , 16-Air duct for equipment.

[0022] The refrigerant is compressed by the 1-compressor, and cooled and dehumidified by the 14-normal temperature and humidity wind through the 8-evaporator to obtain dry cold air.

[0023] The dry cold air diffuses into the 4-air-cooled surface cooler, and the dry cold air is heated by the high temperature generated by the compressed refrigerant of the 1-compressor.

[0024] After the heat exchange, the higher temperature refrigerant is cooled again th...

Embodiment 2

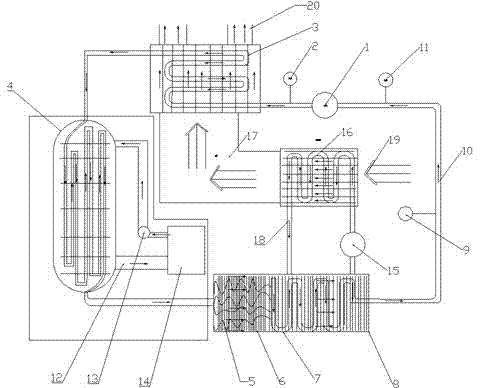

[0027] combined with figure 2 , according to an integrated energy-saving dehumidification heating device of the present invention, it consists of 1-compressor, 2-high pressure gauge, 3-air-cooled surface cooler, 4-volute tube type surface cooler, 5-capillary tube, 6-refrigerating Water, 7-Evaporator, 8-Water tank, 9-Oil and gas separator, 10-Freon pipeline, 11-Low pressure gauge, 12-Water tower chilled water pipeline, 13-Water tower pump, 14-Water tower, 15-Water cooling table cooler pump , 16-water-cooled surface cooler, 17-air duct, 18-water-cooled surface cooler water pipe, 19-normal temperature and humidity wind, 20-air duct for equipment.

[0028] The refrigerant is compressed by the 1-compressor, the water in the 8-water tank is cooled by the 8-evaporator, and the cold water is pumped into the 6-water-cooled surface cooler by the 15-water-cooled surface cooler water pump to cool and dehumidify the normal temperature and humidity gas , get dry cold air.

[0029] The dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com