Method for degrading polyethylene glycol terephthalate through combination of bacteria and enzymes

A technology combining polyethylene terephthalate and bacterial enzyme, which is applied in the direction of plastic recycling and recycling technology, can solve the problems of affecting enzyme activity and reducing the pH value of the system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

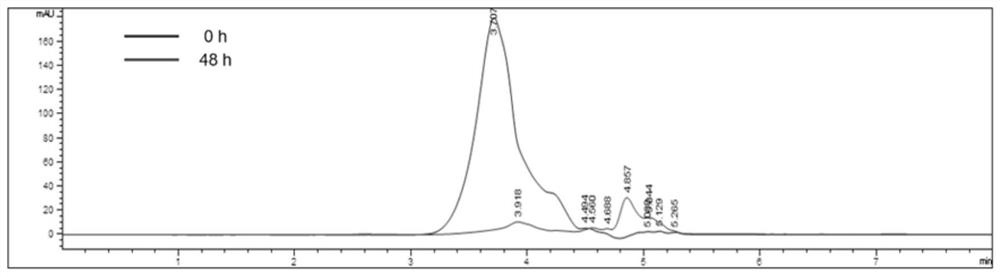

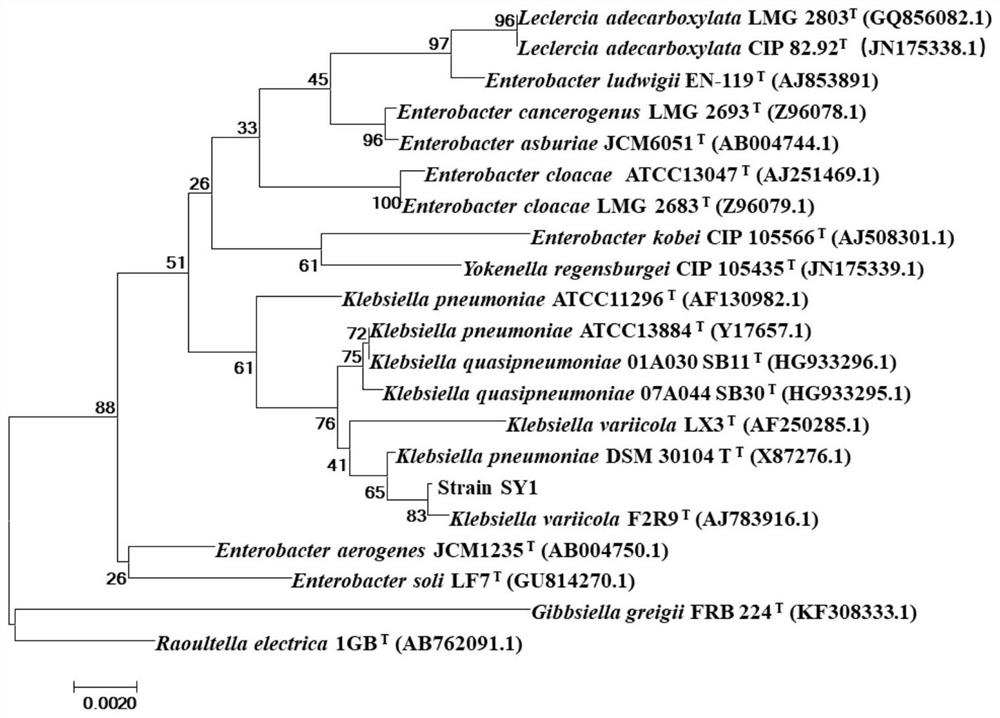

[0033] Screening and Identification of Example 1 Bacterial Strains

[0034] 1. Experimental materials and methods

[0035] 1.1 Medium:

[0036] LB liquid medium (g / L): yeast extract (5.0), peptone (10.0), NaCl (10.0), solvent is water, adjusted to pH 7.0, sterilized at 115°C for 30 minutes;

[0037] LB solid medium is 20g / L agar added to LB liquid medium.

[0038] BSM medium (i.e. basic inorganic salt medium, g / L): K 2 HPO 4 ·3H 2 O(1.0), NaCl(1.0), (NH 4 ) 2 SO 4 (0.5), MgSO 4 ·7H 2 O(0.4), CaCl 2 (0.0755), FeCl 3 ·6H 2 O(0.0143), the solvent is water, adjusted to pH 7.5, sterilized at 115°C for 30min;

[0039] Add 20g / L agar to BSM solid medium.

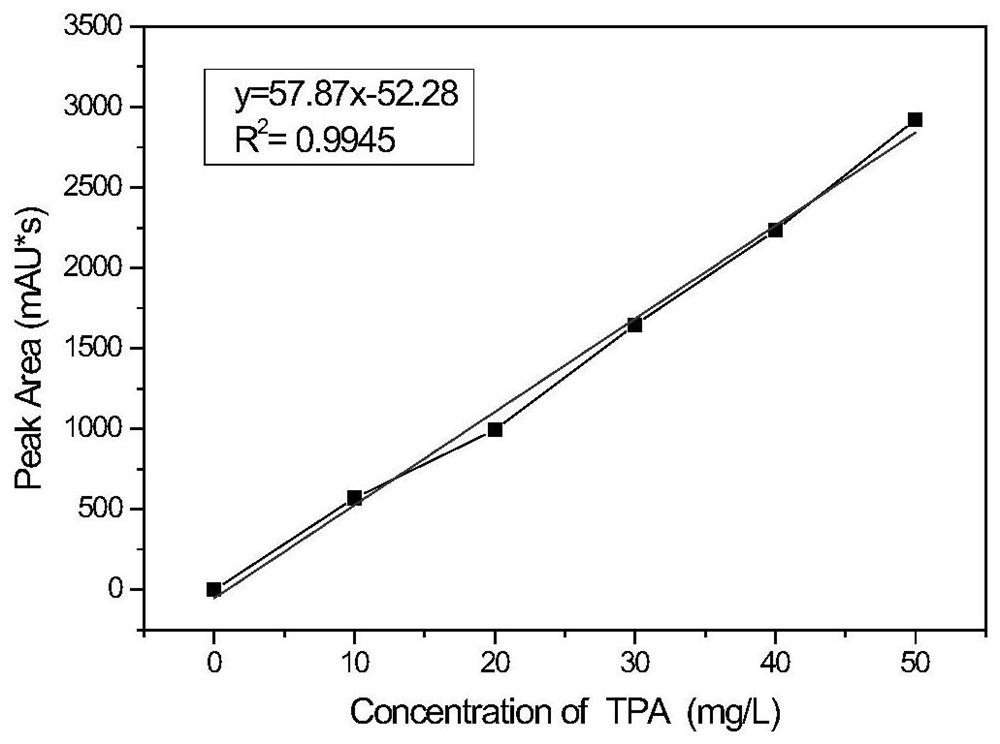

[0040] TPA liquid medium: add terephthalic acid (TPA) (dissolved in DMSO, stock solution concentration is 250mg / mL) in BSM medium, make the final concentration of TPA in the solution be 250mg / L.

[0041] TPA solid medium: add 20g / L agar to TPA liquid medium.

[0042] 1.2 Screening of TPA degrading bacteria

[0043] E...

Embodiment 2

[0066] 1. Experimental materials

[0067] Klebsiella variicola SY1 (Klebsiella variicola SY1), preserved in the China Center for Type Culture Collection, the preservation number is CCTCC NO: M 2020198, the preservation date is June 10, 2020, the address is Wuhan, China, Wuhan University, postcode 430072 .

[0068] Candida antarctica cutinase HiC (Novozym 51032) was purchased from Chengdu Ainahua Chemical Co., Ltd., with a nominal esterase activity of 15kU / g and a protein content of 1.424mg / mL; lipase CALB (Candida antarctica lipaseB, CALB) Purchased from Beijing Gao Ruisen Technology Co., Ltd., the nominal esterase activity is 5kU / g, and the protein content is 1.8mg / mL.

[0069] lcPET (low-crystallinity PET, purchased from Shaoxing Xiangyu Green Packaging Co., Ltd.), is a plastic particle of 3.0mm×2.5mm×2.0mm, with a crystallinity of 11.62%.

[0070] boPET (biaxially oriented PET, purchased from Shaoxing Xiangyu Green Packaging Co., Ltd.), is a plastic film with a thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com