Three-PE anti-corrosion spiral steel pipe formula material and preparation method thereof

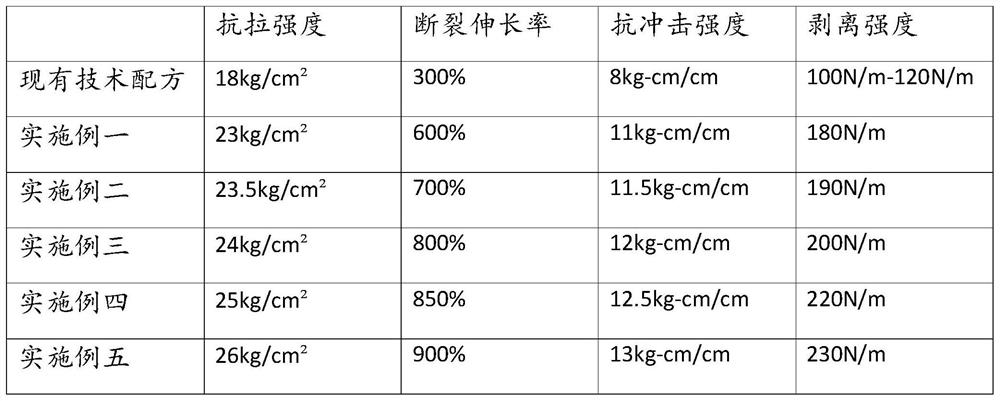

A technology of spiral steel pipe and formula, which is applied in the field of spiral steel pipe, can solve the problems of poor bonding effect of the bonding resin layer, large falling force of the material piece, and brittle surface layer, etc., and achieves strong bonding effect, high tensile strength, and strong impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

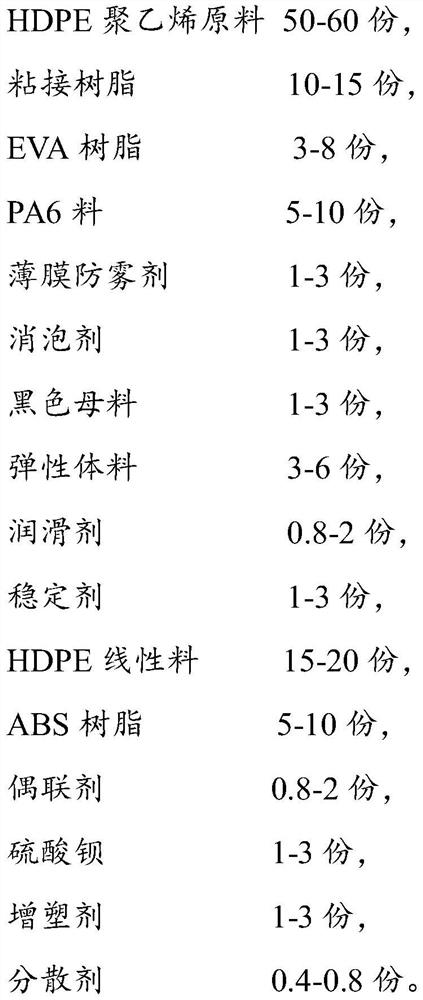

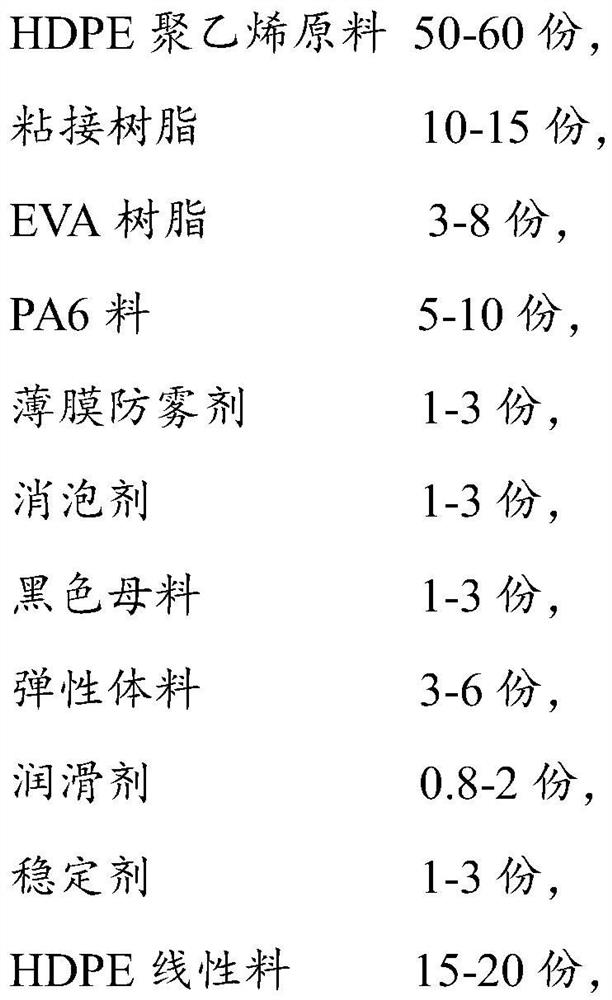

[0019] See figure 1 The three PE anticorrosive spiral steel pipe formulation of the present embodiment includes 50 parts by weight of the following weight: 10 parts of the HDPE polyethylene, 10 parts of the bonding resin, 3 EVA resin, 5 parts of PA6, 1 part of the film anti-fogging agent , 1 defoamer, 1 black masterbatch, 3 elastic materials, 0.8 lubricants, 1 stabilizer, 15 parts of HDPE, 5 parts of ABS resin, 0.8 parts of coupling agent, 1 coplanate , 1 plasticizer, 0.4 dispersant.

[0020] The present invention also provides a method of preparing the three PE anti-corrosion spiral steel pipe, including the following steps:

[0021] Step 1: It is weighing the following components by weight: 50 parts of the HDPE polyethylene raw materials, 10 parts of the resin, 3 parts of EVA resin, 5 parts of PA6, 1 membrane anti-fog, 1 defoam, black mother 1 part, 3 elastomeric materials, 0.8 lubricants, 1 stabilizer, 15 parts of HDPE, 5 parts of ABS resin, 0.8 parts of the coupling agent, 1 b...

Embodiment 2

[0025] See figure 1 The three PE anticorrosive spiral steel tube formulation of the present embodiment includes a component of the following weight: 55 parts of HDPE polyethylene raw materials, 12 parts of the bonded resin, 5 parts of EVA resin, 7 parts of PA6, 2 parts of the film. , 1 defoamer, 2 black masterbatch, 4 parts of the elastic body, 1 lubricant, 2 parts of the stabilizer, 16 parts of HDPE, 6 parts of ABS resin, 1 coupling agent, 2 copies of sulfate , 1 plasticizer, 0.5 dispersant.

[0026] The present invention also provides a method of preparing the three PE anti-corrosion spiral steel pipe, including the following steps:

[0027] Step 1: Tighted by weight: 55 parts of HDPE polyethylene raw materials, 12 parts of the bonding resin, 5 parts of EVA resin, 7 parts of PA6, 2 parts of the film, 1 defoamer, black mother 2 parts, 4 parts of elastic body, 1 lubricant, 2 stabilizers, 16 parts of HDPE, 6 parts of ABS resin, 1 coupling agent, 2 copper sulfate, 1 plasticizer, dis...

Embodiment 3

[0031] See figure 1 The three PE anticorrosive spiral steel tube formulation of the present embodiment includes a component of the following weight: 56 parts of the HDPE polyethylene raw material, 13 parts of the bonding resin, 5 parts of EVA resin, 7 parts of PA6, and 2.5 parts of the film. 1.8 parts of antifoaming agent, 2 black masterbats, 4 parts of the elastomer, 1 lubricant, 2 stabilizers, 17 parts of HDPE, 8 parts of ABS resin, 1.5 copies, barium sulfate, barium sulfate 2.2 parts , 2 plasticizers, 0.6 dispersant.

[0032] The present invention also provides a method of preparing the three PE anti-corrosion spiral steel pipe, including the following steps:

[0033] Step 1: It is weighing 56 parts of the following components of HDPE polyethylene raw materials, 13 parts of the resin, 5 parts of EVA resin, 7 parts of PA6, 2.5 parts of the film, 1.8 copper, black masterbatch 2 serviles, 1.2 parts of the lubricant, 2 stabilizers, 17 parts of HDPE, 8 parts of the ABS resin, 1.5 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com