Preparation method of high-purity indium oxide

An indium oxide, high-purity technology, applied in the direction of chemical instruments and methods, inorganic chemistry, process efficiency improvement, etc., can solve the problems of long processing time, rising cost, difficult filtration, etc., achieve easy operation, reduce production cost, and connect strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

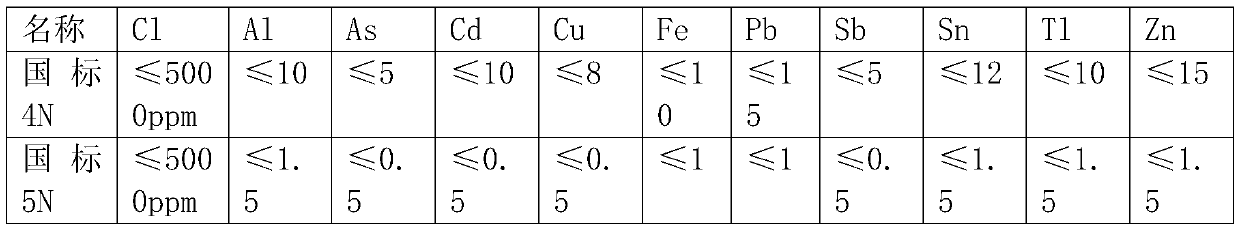

Examples

preparation example Construction

[0025] A method for preparing high-purity indium oxide, comprising the following steps:

[0026] The first step: preparing an electrolyte solution with a pH value of 0.5-1, the composition and content of the electrolyte solution are: In 3 +70-100g / L, sodium chloride 70-90g / L, thiourea 1-15mg / L, potassium iodide 1-10mg / L, gelatin 0.1-0.5g / L, and the rest is ultrapure water;

[0027] The second step: first electrolyzing the above electrolytic solution to obtain indium obtained by electrolysis, then hydrolyzing the indium obtained by electrolysis to obtain indium obtained by hydrolysis, and then drying the indium obtained by hydrolysis to obtain indium obtained by drying;

[0028] Step 3: first heat the indium obtained by drying above to obtain a precursor, and then calcine the precursor to obtain high-purity indium oxide.

[0029] The pH value of the electrolyte is 0.8, and the composition and content of the electrolyte are: In 3+ 85g / L, sodium chloride 80g / L, thiourea 7.5mg / L...

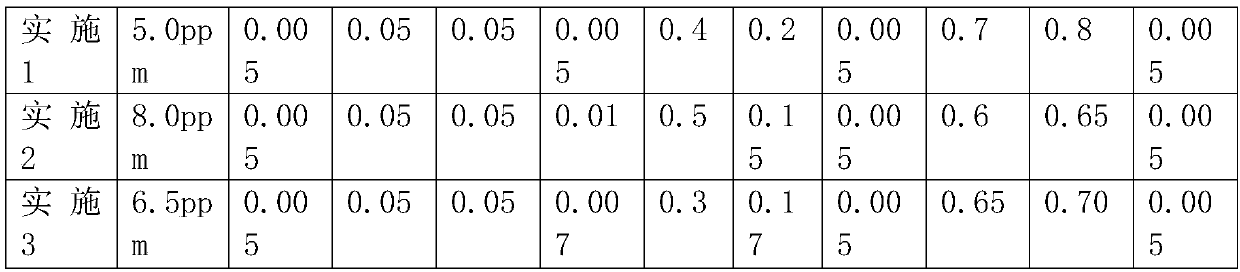

Embodiment 1

[0046] Prepare In first 3 +70g / L, sodium chloride 70g / L, thiourea 1mg / L, potassium iodide 1mg / L, gelatin 0.1g / L, pH=0.5 electrolyte solution, and then the electrolyte solution is electrolyzed, hydrolyzed, and dried to obtain Dried the obtained indium (that is, high-purity indium), and then placed the dried indium in a graphite crucible for heating. The heating temperature was 180°C. After heating for 1 hour, the precursor was obtained, and then the precursor was placed in the muffle furnace for the procedure. The temperature was raised to 800° C. in 4 hours, and then kept at a constant temperature for 2 hours to finally obtain high-purity indium oxide.

Embodiment 2

[0048] Basic content is the same as embodiment 1, the difference is:

[0049] Prepare In first 3 +100g / L, sodium chloride 90g / L, thiourea 15mg / L, potassium iodide 10mg / L, gelatin 0.5g / L, electrolyte solution with pH=1, then, the heating temperature in graphite crucible is 200℃ .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com