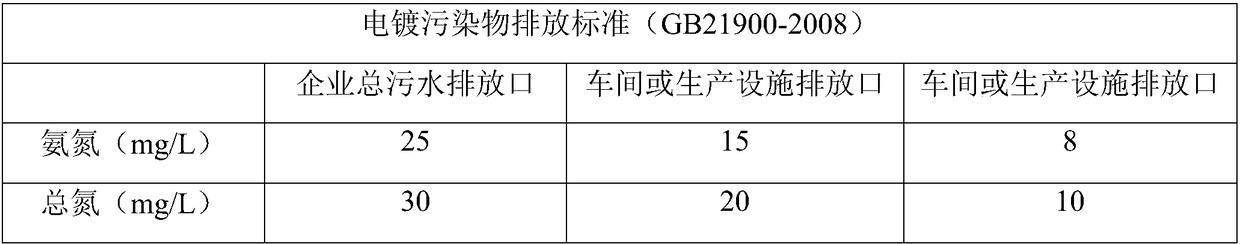

Ammonia and nitrogen-free chemical nickel treatment process

A technology of ammonia nitrogen chemistry and treatment process, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problems of cross contamination, poor stability, easy to turn over the tank, etc., and achieve low operating costs and long average life , excellent binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

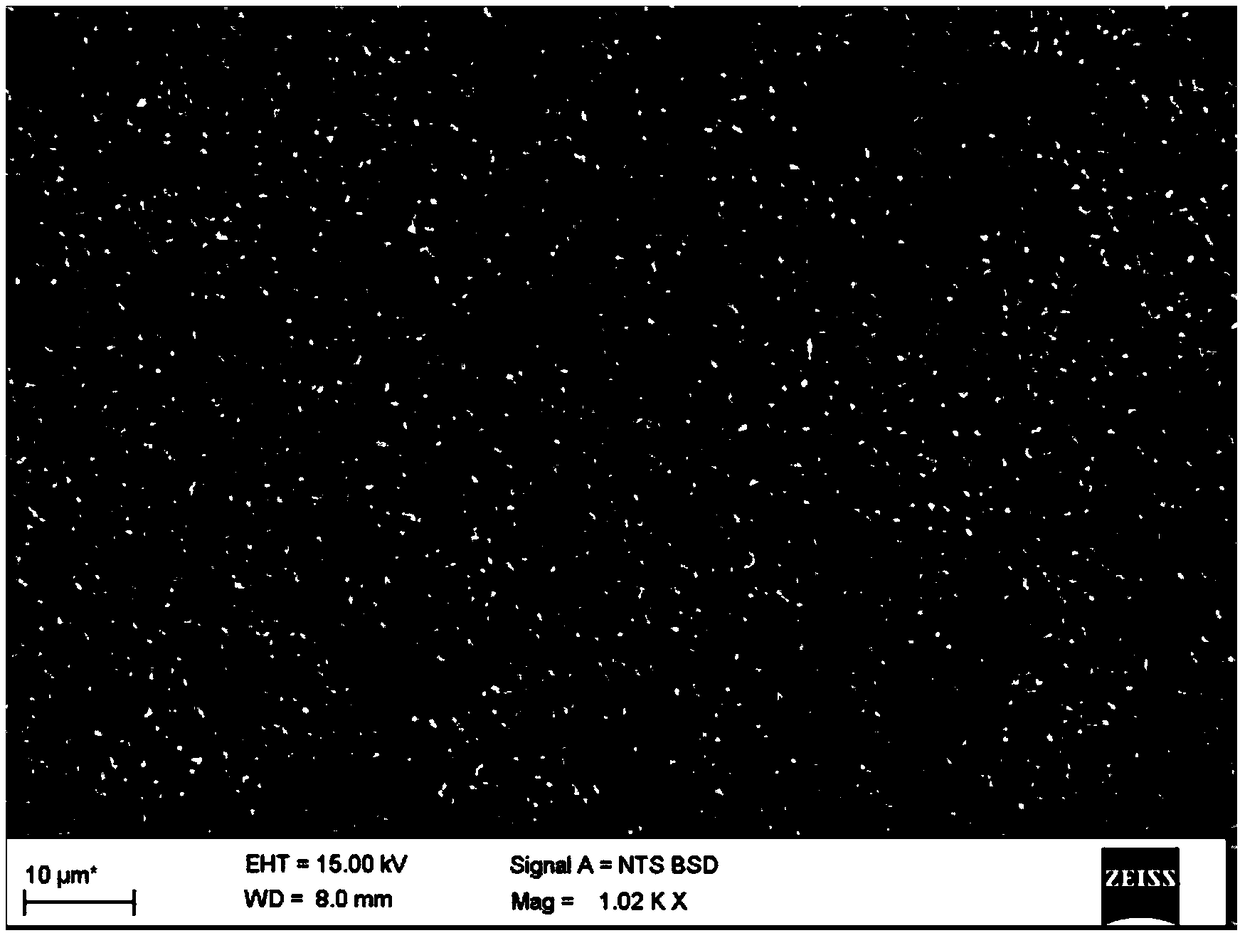

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the examples.

[0035] An ammonia-nitrogen-free chemical nickel treatment process includes the preparation and maintenance of an ammonia-free chemical nickel solution.

[0036] The preparation of ammonia-nitrogen-free chemical nickel solution comprises the steps:

[0037] (1) Inject pure water into the tank first;

[0038] (2) Add the cylinder opener under uniform stirring;

[0039] (3) then add nickel sulfate, stir;

[0040] (4) Add sodium hypophosphite, stir;

[0041] (5) Add pure water to the required water level;

[0042] (6) If necessary, adjust the pH value to the operating range with sodium hydroxide or dilute sulfuric acid.

[0043] Wherein, nickel sulfate is nickel sulfate hexahydrate, and sodium hypophosphite is sodium hypophosphite monohydrate.

[0044] To prepare 1L o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com