A kind of preparation method of high light transmittance and high haze superhydrophobic coating

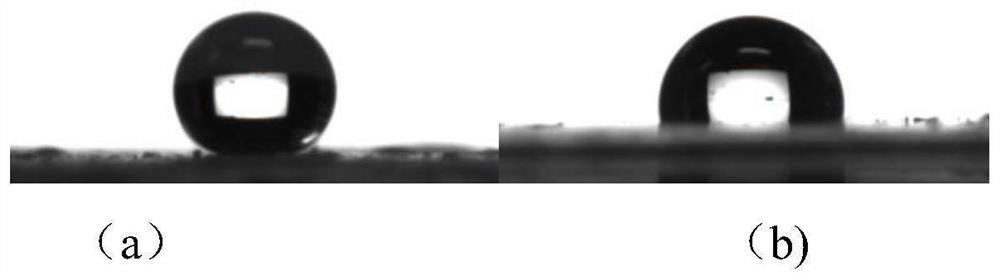

A super-hydrophobic coating and high light transmittance technology, which is applied in coatings, fireproof coatings, etc., can solve problems such as low haze, failure to reach a super-hydrophobic state, and difficulty in meeting high haze and high light transmittance at the same time. Achieve the effect of simple operation, simple preparation method and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

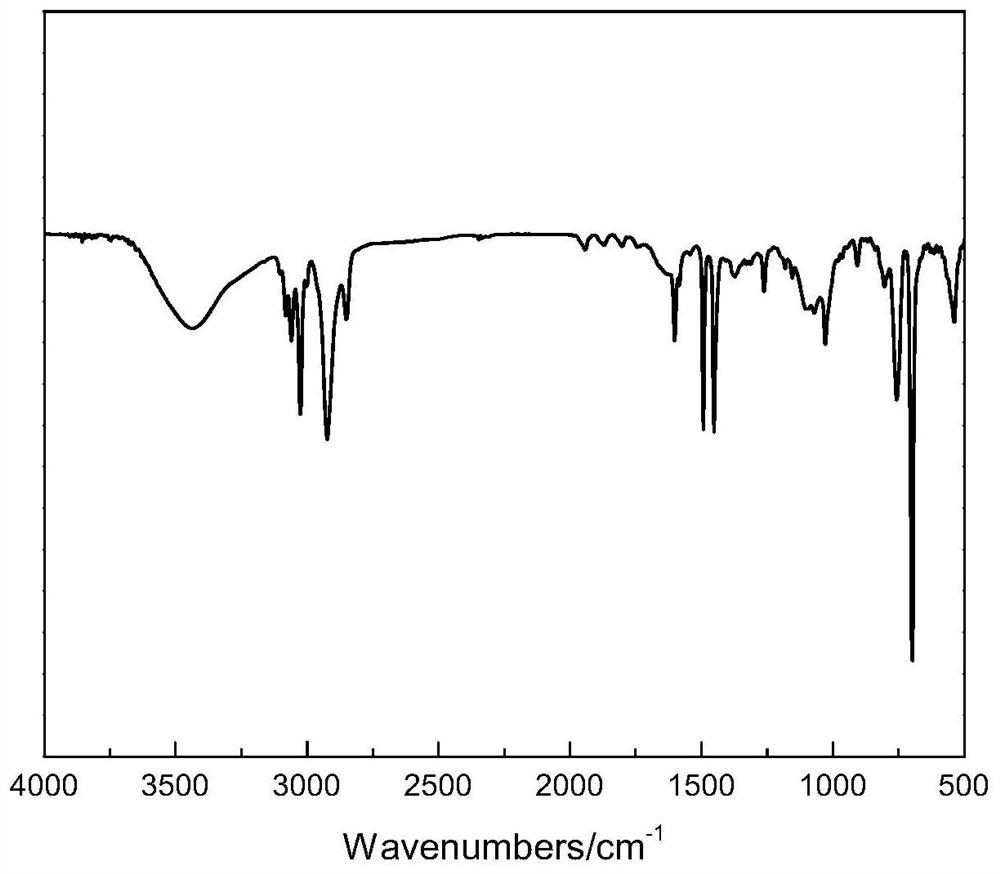

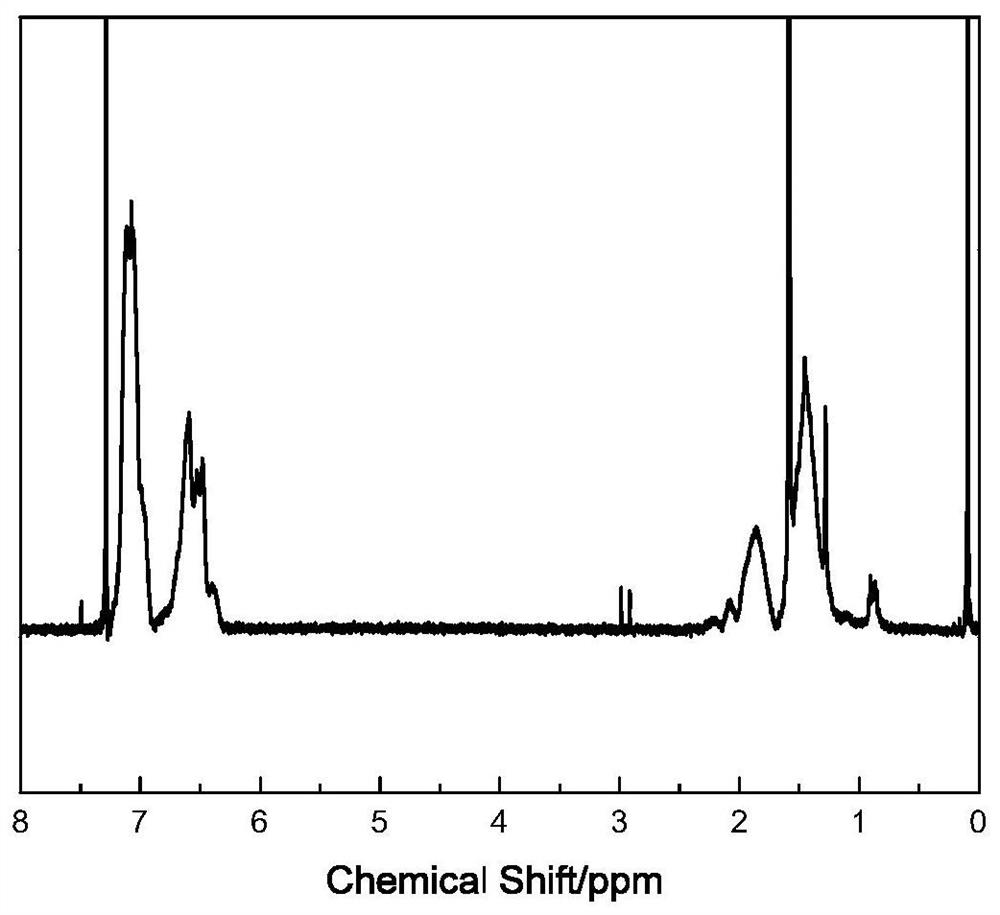

[0020] (1) Synthesis of star copolymer POSS-PS

[0021] 0.42g of octachloropropyl cage silsesquioxane, 0.04g of cuprous chloride and 0.2g of 2,2'-bipyridine, 9.2ml of styrene, 3ml of N,N-dimethylamide , added to a Schlenk bottle, and reacted at 110° C. for 24 hours by atom transfer radical polymerization (ATRP) to synthesize a star-shaped copolymer POSS-PS.

[0022] (2) Synthesis of room temperature curing silicone rubber

[0023] Mix 10 g of hydroxyl-terminated polysiloxane with 1 g evenly to obtain room temperature curing silicone rubber.

[0024] (3) prepare superhydrophobic coating;

[0025] Weigh 20mg of star copolymer POSS-PS star copolymer and dissolve in 1ml of dichloromethane (solubility is 20mg / ml), 10mg of room temperature curing silicone rubber is dissolved in 1ml of dichloromethane, ultrasonically until dissolved, the two solutions Mix evenly by volume 1:1 to obtain a mixed solution. The glass substrate is placed in a n-hexane coagulation bath, and then the ab...

Embodiment 2

[0044] (1) Synthesis of star copolymer POSS-PS

[0045] Mix 0.42g of octachloropropyl cage silsesquioxane, 0.04g of cuprous chloride and 0.2g of 2,2'-bipyridyl, 6.9ml of styrene, 2ml of N,N-dimethylamide , added to a Schlenk bottle, and reacted at 110° C. for 24 hours by atom transfer radical polymerization (ATRP) to synthesize a star copolymer POSS-PS.

[0046] (2) synthetic room temperature curing silicone rubber, with embodiment 1;

[0047] (3) Prepare super-hydrophobic coating, same as embodiment 1.

Embodiment 3

[0053] (1) Synthesis of star copolymer POSS-PS

[0054] Mix 0.42g of octachloropropyl cage silsesquioxane, 0.04g of cuprous chloride and 0.2g of 2,2'-bipyridine, 4.6ml of styrene, 1.6ml of N,N-dimethyl The amide was added into a Schlenk bottle, and reacted at 110° C. for 24 hours by atom transfer radical polymerization (ATRP) to synthesize a star-shaped copolymer POSS-PS.

[0055] (2) synthetic room temperature curing silicone rubber, with embodiment 1;

[0056] (3) Prepare super-hydrophobic coating, same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com