Production and purification process of a hemorrhagic fever vaccine

A technology for vaccine production and hemorrhagic fever, applied to biochemical equipment and methods, microorganisms, antibody medical components, etc., can solve the problems of high technical requirements, small cell volume, and large cell volume, so as to improve purification efficiency and one-time investment Less, improve the effect of cell homeostasis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A hemorrhagic fever vaccine production and purification process, comprising the following steps:

[0048] (1) Cell subculture: take Vero cell 138 generation cells recovery culture and subculture expansion to 143 generation, wherein, cell culture medium is made of bovine serum (the content of bovine serum is 10% of the total volume of cell culture medium), MEM solution and additives Composition, wherein the additives include: 30mg / L inositol, 20mg / L iron sodium edetate, 20mg / L hydrolyzed soybean protein, 15mg / L phosphatidylserine and 35mg / L N-acetylneuraminic acid; 37°C Culture, the subculture ratio of the cell factory is 1:4, and the production process is a non-toxic production process;

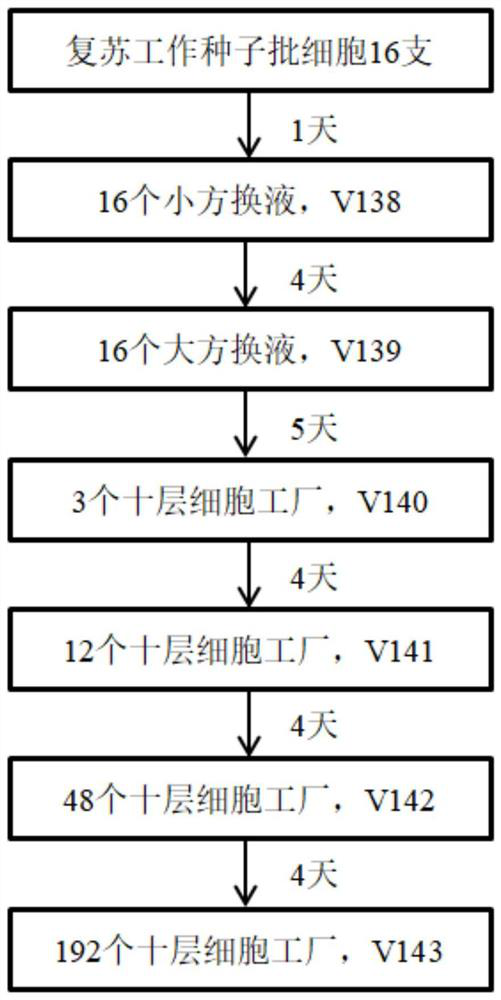

[0049] The specific flow chart of cell passage is as follows: figure 1 As shown, the small square is 30cm 2 Cell bottle, generous to 140cm 2 Cell bottle, the ten-story cell factory culture area is 6320cm 2 ;

[0050] (2) Virus infection: after cell expansion and passage to 143 gener...

Embodiment 2

[0062] The only difference from Example 1 is that the additives include: 40mg / L inositol, 30mg / L iron sodium edetate, 50mg / L hydrolyzed soybean protein, 45mg / L phosphatidylserine and 40mg / L N-acetyl neuro acid.

Embodiment 3

[0064] The only difference from Example 1 is that the additives include: 35mg / L inositol, 28mg / L ferric sodium edetate, 42mg / L hydrolyzed soybean protein, 25mg / L phosphatidylserine and 36mg / L N-acetyl neuro acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com