Preparation method of efficient novel chicken ovalbumin chelated zinc

A chicken egg white and chelated zinc technology, applied in the preparation method of peptides, ovalbumin, albumin peptides, etc., can solve the problems of affecting the absorption and utilization of other trace elements, large influence of intestinal contents, and unsatisfactory absorption rate. , to achieve the effect of fast industrial efficiency, convenient industrial production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

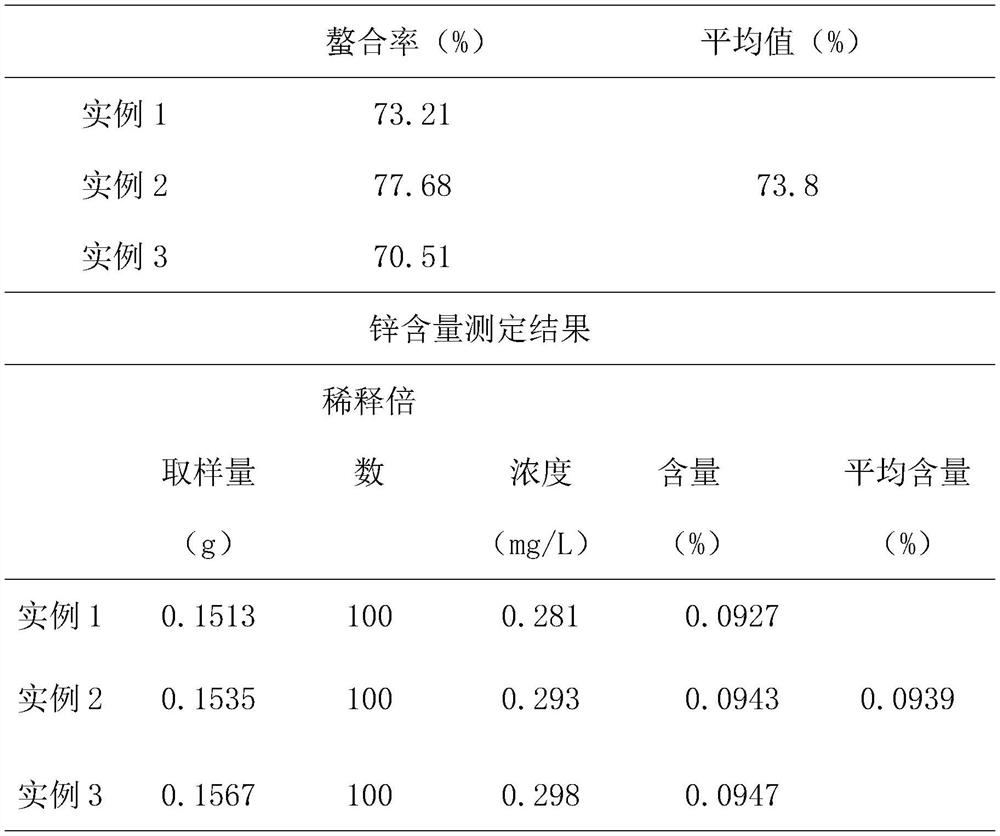

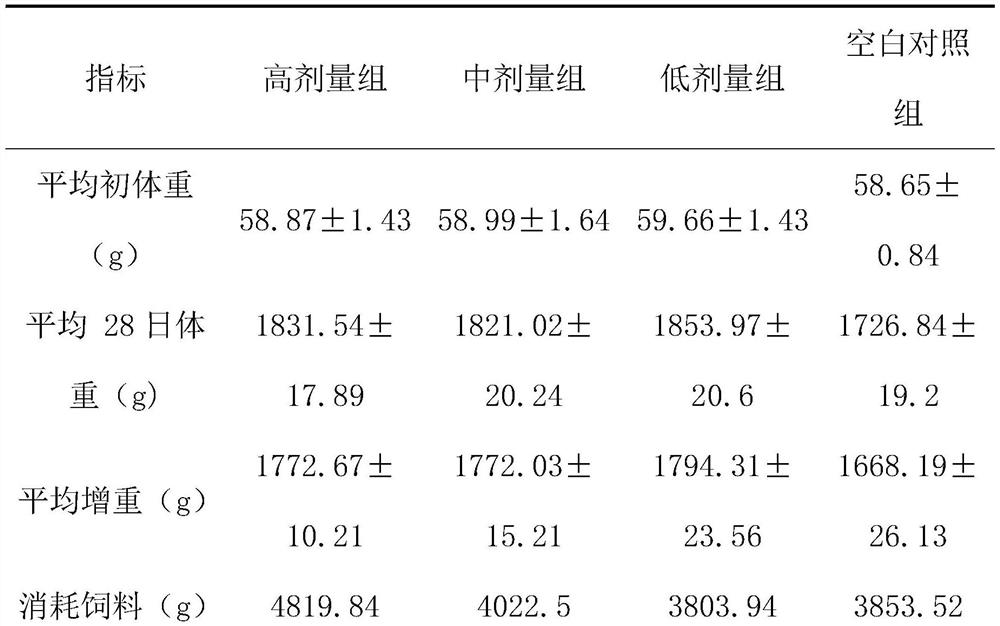

Embodiment 1

[0035] The preparation method of the chicken ovalbumin (ovalbumin) OVA peptide chelated zinc provided by the present embodiment comprises the following steps:

[0036] (1) Collection of chicken ovalbumin: clean the collected eggs, then sterilize them with a disinfectant, separate the egg whites from the egg yolks at 4°C under sterile conditions, filter and take the egg whites and go through the pasteurization step. The condition for sterilization is to heat the filtrate to 65-68°C and keep this temperature for 15 minutes, and then rapidly cool it to 4-5°C within 3 minutes. .

[0037](2) Enzymolysis: Chicken ovalbumin was enzymatically hydrolyzed for 1 hour, at a temperature of 35° C., with an enzyme-to-substrate ratio of 1%, and pH 5 was adjusted, and corresponding enzyme preparations were added for enzymolysis.

[0038] (3) Inactivation: After enzymatic hydrolysis, heat passivation at 40°C for 10 minutes twice, then cool to room temperature

[0039] (4) Centrifugation: Afte...

Embodiment 2

[0043] (1) Collection of chicken ovalbumin: clean the collected eggs, then sterilize them with a disinfectant, separate the egg whites from the egg yolks at 4°C under sterile conditions, filter and take the egg whites and go through the pasteurization step. The condition for sterilization is to heat the filtrate to 65-68°C and keep this temperature for 15 minutes, and then rapidly cool it to 4-5°C within 3 minutes. .

[0044] (2) Enzymolysis: chicken ovalbumin enzymolysis time is 3 hours, temperature is 45° C., enzyme-to-substrate ratio is 3%, pH is adjusted to 7, and corresponding enzyme preparations are added for enzymolysis.

[0045] (3) Inactivation: After enzymatic hydrolysis, heat the passivation temperature at 55°C for 15 minutes for 2 times, and cool to room temperature

[0046] (4) Centrifugation: After inactivation, the cooled liquid is centrifuged. During centrifugation, the rotating speed of the centrifuge is 4200r / min, and the centrifugation time is 7min. Get th...

Embodiment 3

[0049] (1) Collection of chicken ovalbumin: clean the collected eggs, then sterilize them with a disinfectant, separate the egg whites from the egg yolks at 4°C under sterile conditions, filter and take the egg whites and go through the pasteurization step. The condition for sterilization is to heat the filtrate to 65-68°C and keep this temperature for 15 minutes, and then rapidly cool it to 4-5°C within 3 minutes. .

[0050] (2) Enzymolysis: chicken ovalbumin enzymolysis time is 5 hours, temperature is 55° C., enzyme-to-substrate ratio is 5%, pH is adjusted to 9, and corresponding enzyme preparations are added for enzymolysis.

[0051] (3) Inactivation: After enzymatic hydrolysis, heat the passivation temperature at 65°C for 15 minutes and passivate once for 15 minutes, then cool to room temperature

[0052] (4) Centrifugation: after inactivation, the cooled liquid is centrifuged. During centrifugation, the rotating speed of the centrifuge is 4500r / min, and the centrifugatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com