Optimization design method and system of current transformer electricity-taking power supply

A technology of current transformer and optimized design, applied in the field of optimization design method and system of current transformer power taking power supply, can solve the problems of insufficient power taking power, reducing magnetic permeability of magnetic core, easy saturation of power magnetic core, etc. Convergence speed, avoid output current distortion, improve the effect of defects regardless of hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

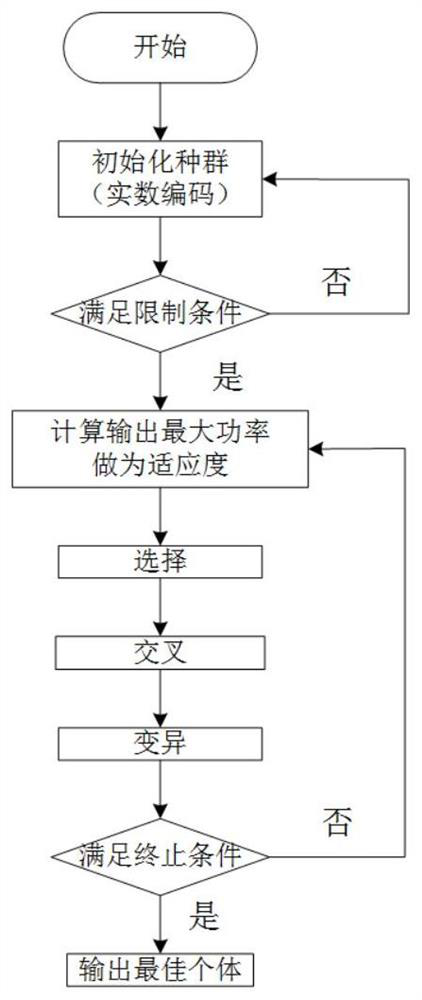

[0072] A method for optimizing the design of a current transformer power supply of the present invention comprises the following steps:

[0073] S1. Establish an output model of the power-taking current transformer that takes into account the influence of the power processing module, analyze the relationship between the output power of the current transformer and the voltage of the filter capacitor, and obtain the maximum output power and the conditions for outputting the maximum power;

[0074] S101. Establish an output model of the power-taking CT taking into account the influence of the power processing module, and obtain a mathematical model that can be used to analyze the output characteristics of the power-taking CT;

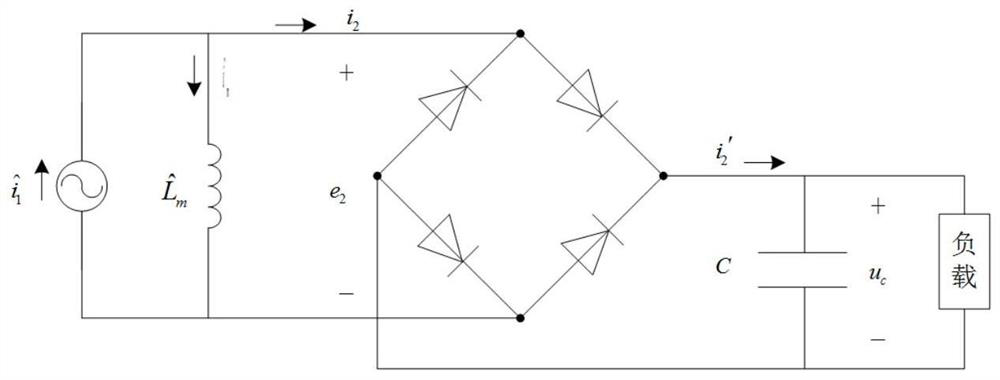

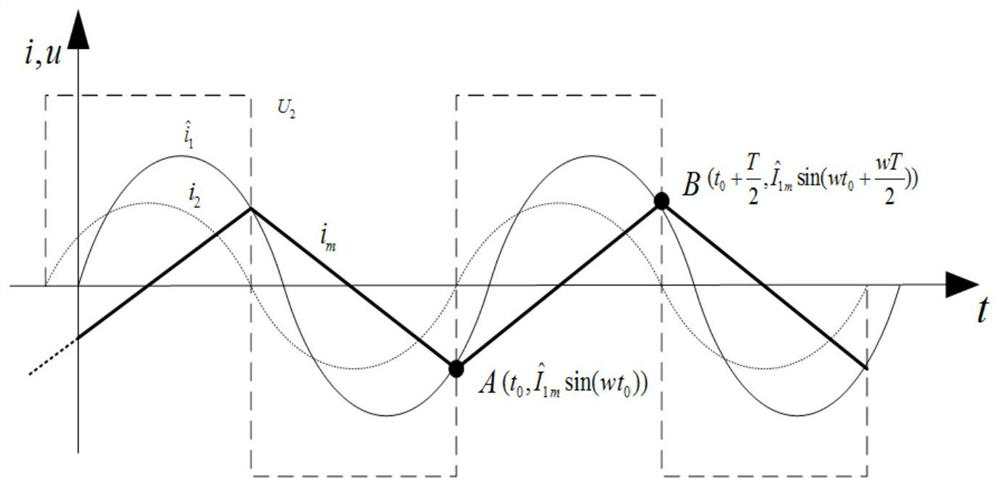

[0075] see figure 1 , in the case of considering the rectifier circuit and the non-linear load of the latter stage, the following assumptions are made for the latter stage of the circuit: Assume that the filter capacitor C is large enough, so when the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com