Display panel, reinforcing method thereof and display device

A technology for display panels and display devices, applied in electrical components, electric solid state devices, circuits, etc., can solve the problems of reducing the curling reliability of flexible display panels, easily generating microcracks, etc., and achieve the improvement of curling reliability and edge strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

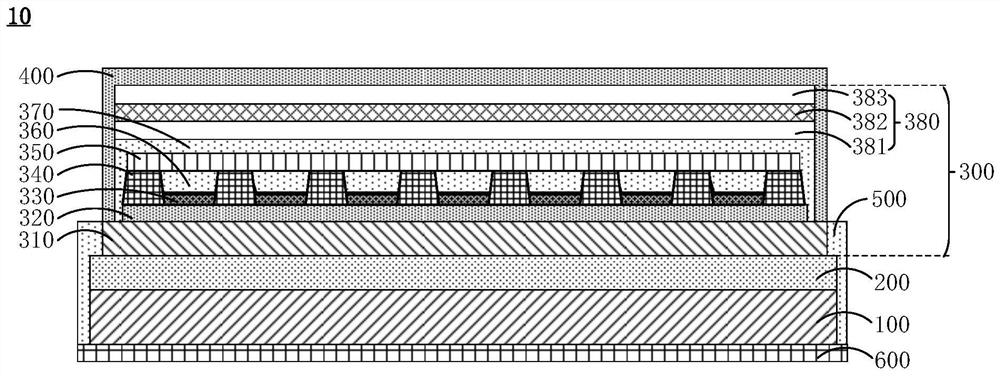

[0027]The display function layer 300 includes a thin film transistor 310 , a flat layer 320 , an anode 330 , an emission definition layer 340 , a light emitting layer 350 , a cathode 360 , an organic encapsulation layer 370 , and an encapsulation protection layer 380 , which are sequentially stacked. Wherein, the thin film transistor 310 can be a common thin film transistor in the field, and it is not limited. The planarization layer 320 is used to planarize the thin film transistor 310 , which facilitates the deposition of subsequent film layers. The anode 330 and the cathode 360 can be a metal material, or a transparent electrode material, specifically, selected according to the actual situation, for example: one of metals or metal compounds such as Ag, IZO, ITO, Mo, Al, etc. one or a combination of several. The luminescence defining layer 340 adopts a hydrophobic material or obtains a hydrophobic surface by means of heating or the like. The light-emitting layer 350 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com