Sheet-shaped prepreg for fan-out package sealing

A fan-out type and packaging technology, applied in the direction of electrical components, electrical solid-state devices, semiconductor devices, etc., can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0202] Preparation Example 1: Preparation of Support (Preparation of Cellulose Nonwoven Fabric)

[0203] The slurry of microfiber CELISH KY110N (manufactured by Daicel Co., Ltd.) was diluted to 0.2% by weight, and a No. 5C filter paper was prepared using a paper machine with a decompression device (manufactured by Toyo Seiki Co., Ltd., standard square machine). Papermaking was performed as a filter cloth to obtain a moist cellulose nonwoven fabric.

[0204] Blotting papers were stacked on both sides of the obtained wet cellulose nonwoven fabric, and pressed at a pressure of 0.2 MPa for 1 minute. Next, it was pressed at a pressure of 0.2 MPa for 1 minute, then attached to a drum dryer (manufactured by Kumagai Riki Kogyo Co., Ltd.) whose surface temperature was set to 100° C., and dried for 120 seconds to obtain a cellulose nonwoven fabric ( Porosity: 60vol%, unit weight 9.9g / m 2 , Linear thermal expansion coefficient: 5ppm / K, thickness 25μm).

preparation example 2

[0205] Preparation Example 2: Preparation of Support (Preparation of Cellulose Nonwoven Fabric)

[0206] A cellulose nonwoven fabric (porosity: 60 vol%, basis weight 9.9 g / m) was obtained in the same manner as in Preparation Example 1 2 , Linear thermal expansion coefficient: 5ppm / K, thickness 200μm).

Embodiment 1~5

[0208] (Preparation of Sheet Prepreg)

[0209] Curable compositions were prepared according to the formulations described in Table 1.

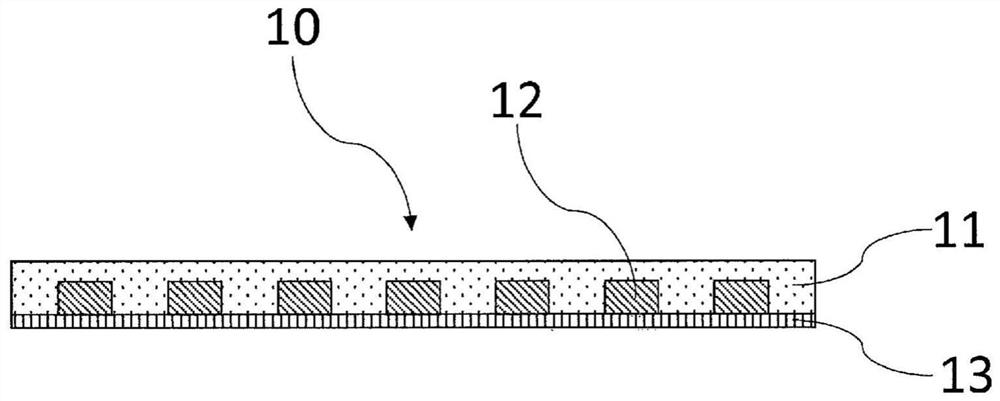

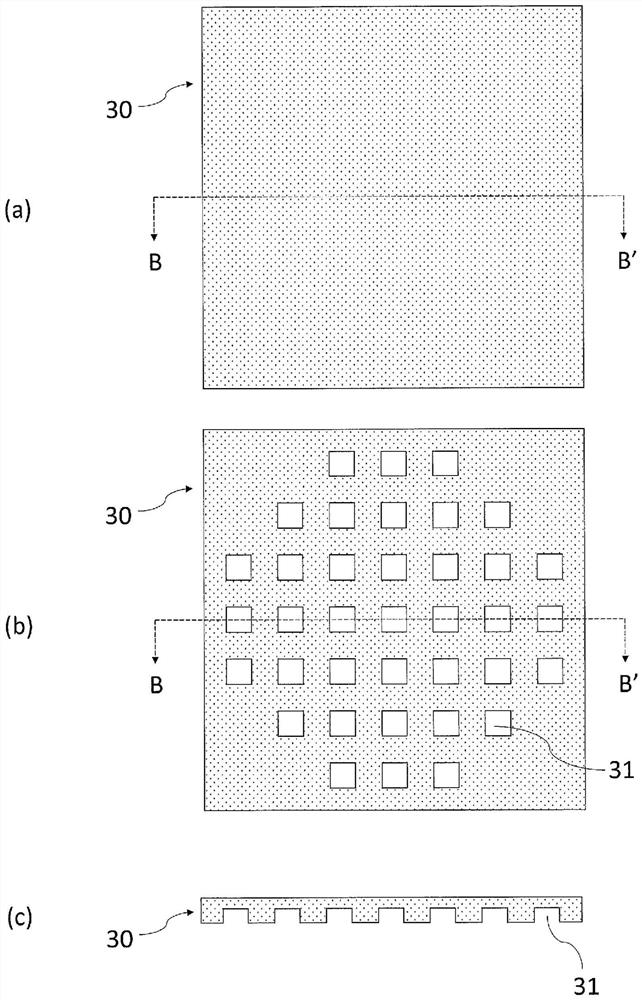

[0210] After the cellulose nonwoven fabric or glass cloth obtained in Preparation Examples 1 and 2 was immersed in the obtained curable composition under reduced pressure, the solvent was removed under reduced pressure and the curable composition was impregnated again. A flat sheet-like prepreg (without through-holes) was produced by infiltration. Table 1 shows the film thickness of the obtained sheet-like prepreg.

[0211]

[0212](Manufacture of sheet-like prepreg with through-holes)

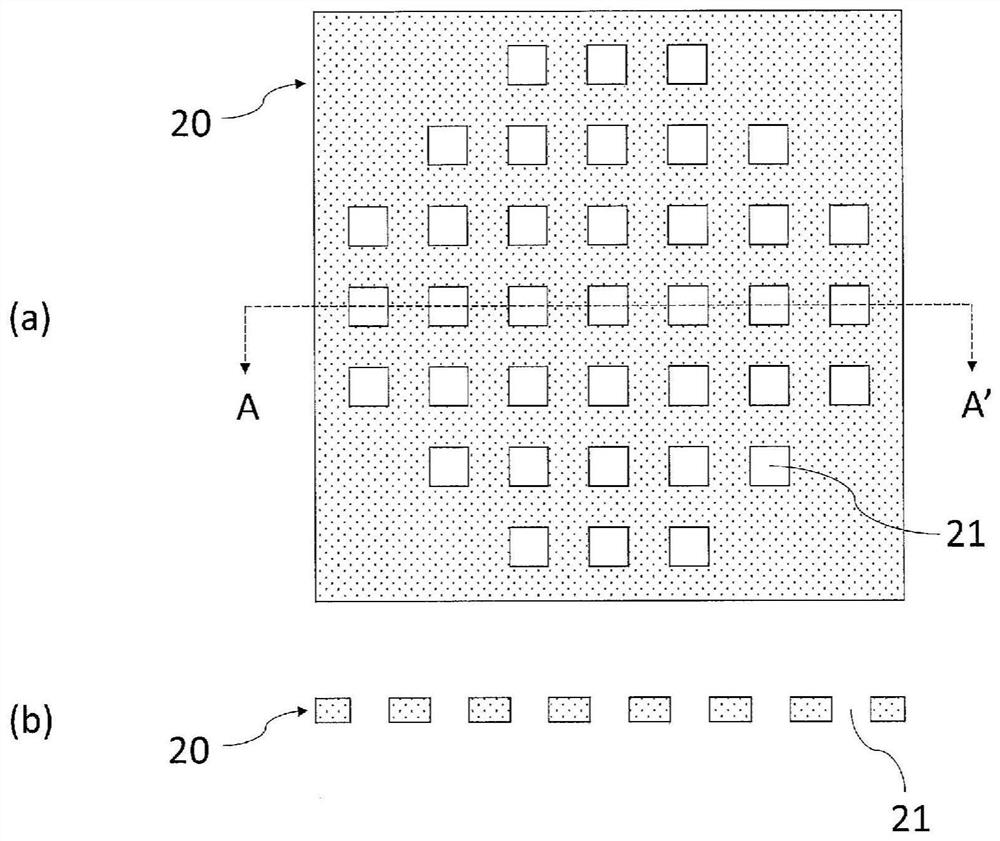

[0213] The sheet-like prepreg obtained above was extracted by punching to obtain a figure 2 A sheet prepreg with 37 10.5 mm square through holes is shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com