Artificial joint with self-repairing textured composite film structure and preparation method

A composite film, artificial joint technology, applied in the field of implant medical devices, can solve the problems of carbon brazing and nano particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

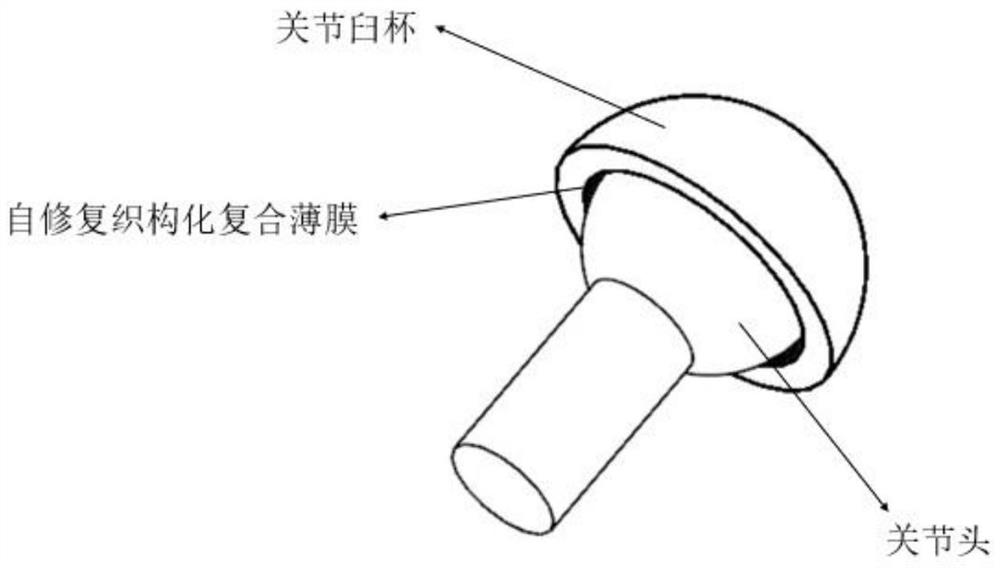

[0032] A method for preparing an artificial joint with a self-repairing textured composite film structure, which is carried out sequentially according to the following steps:

[0033](1) Grind and polish the radiation-crosslinked ultra-high molecular weight polyethylene joint acetabular cup on a polishing machine to a roughness Ra<0.2 μm, and ultrasonically clean them in absolute ethanol and deionized water for 30 min, and blow dry with dry nitrogen, Obtain a smooth inner surface of the acetabular cup;

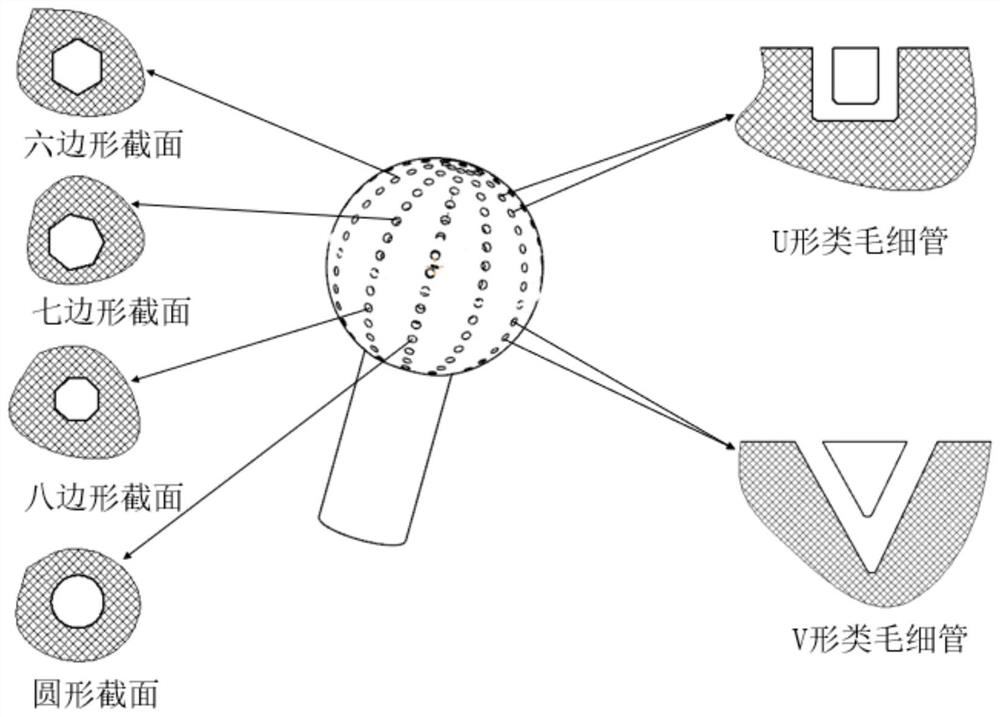

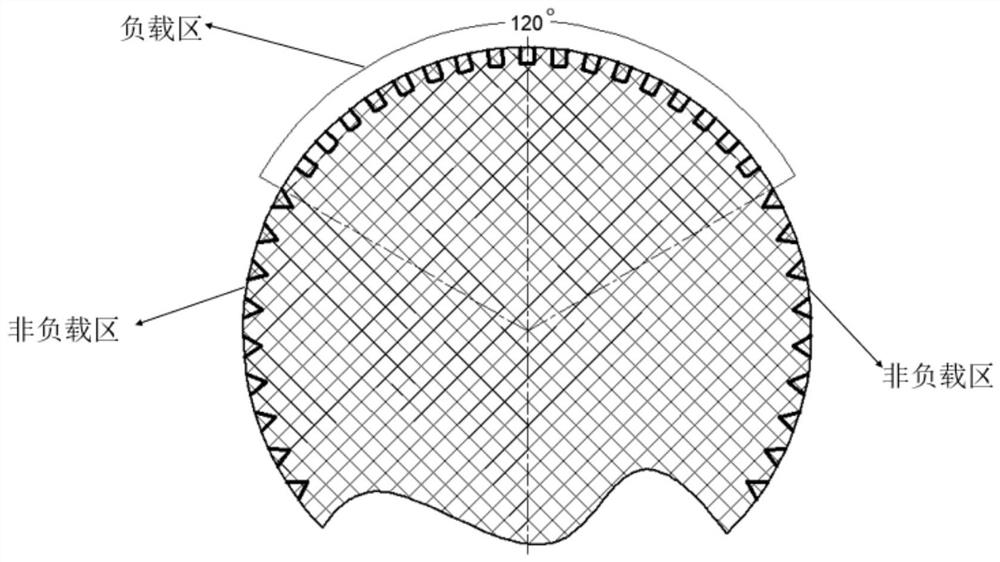

[0034] (2) Using one or two processing methods of laser processing and photolithography processing technology, the circular hole micro-texture regularly arranged on the inner surface of the smooth joint cup is processed, and the diameter of the circular hole micro-texture is 120 μm , the depth is 8 μm, and the coverage area is 30% of the inner surface area of the acetabular cup. The distance between the centers of the micro-textured shape holes is 200 μm to obtain a texture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com