Vermiculite-MXene composite membrane and preparation method and application thereof

A composite membrane and vermiculite technology, applied in the field of nanofiltration membranes, can solve the problems of low pollutant retention rate, poor membrane mechanical properties, and membrane materials that are not resistant to chlorine, etc., and achieve simple preparation methods, low cost, and high water flux Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] A kind of vermiculite-MXene composite film, its preparation method comprises the following steps:

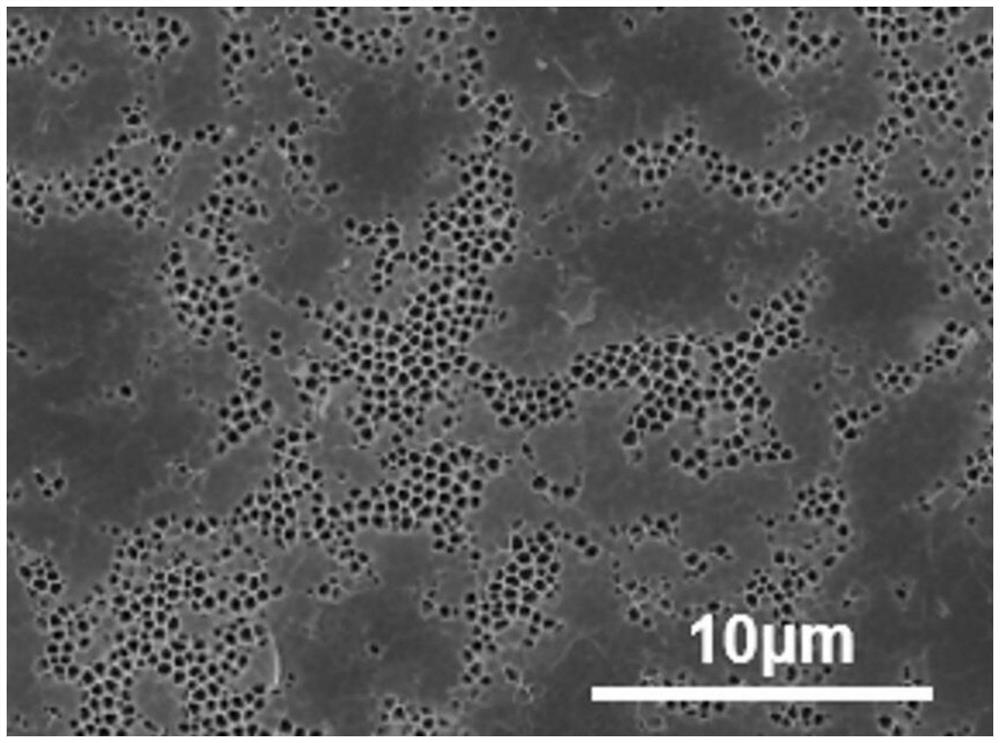

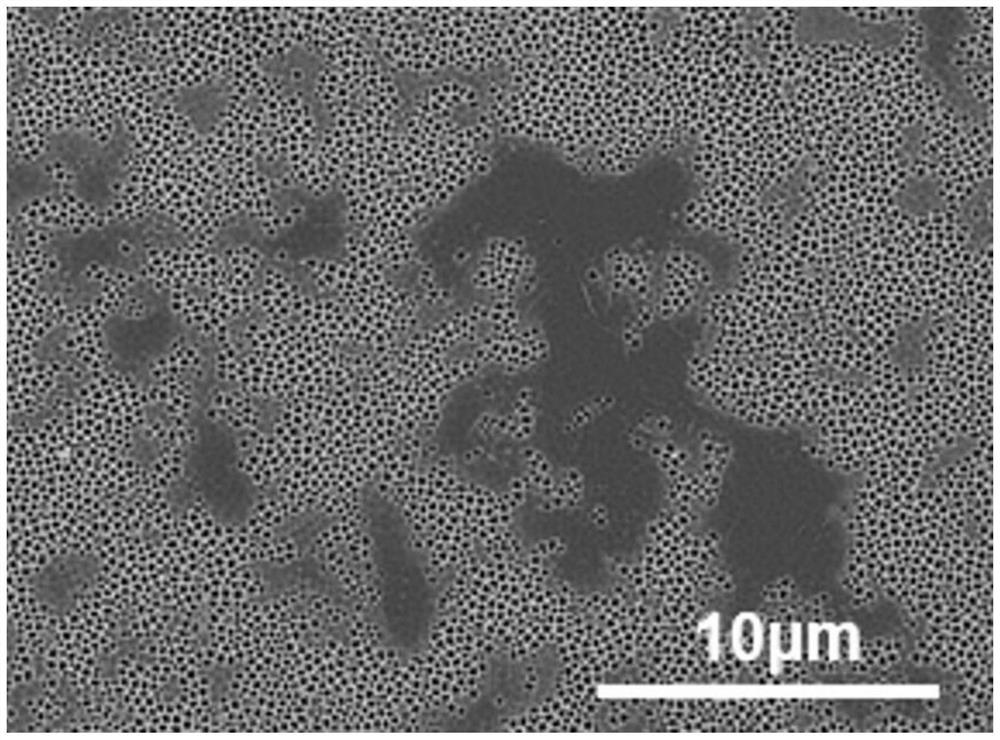

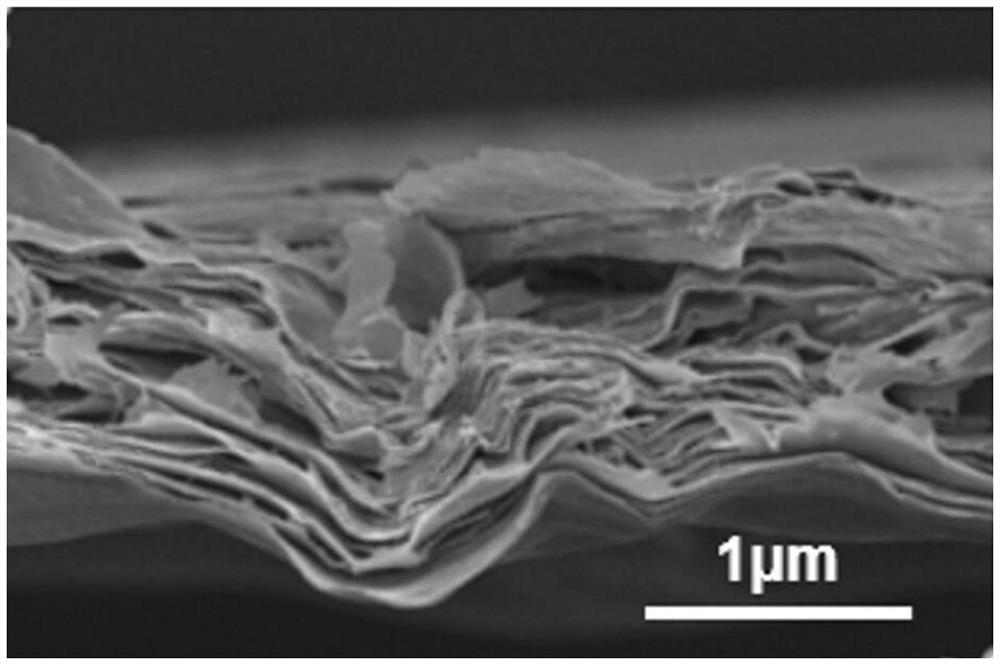

[0041] 1) Put 2g of heat-expandable vermiculite with a transverse dimension of 3mm into a round-bottomed flask, then add 200mL of saturated sodium chloride solution, place the round-bottomed flask in an oil bath at 120°C to reflux for 24 hours, filter, and filter the solids with water Rinse repeatedly with ethanol, then disperse in lithium chloride solution prepared by 10g lithium chloride and 200mL deionized water, reflux at 120°C for 24h, filter, and rinse the filtered solid with water and ethanol repeatedly, then remove The deionized water is centrifuged, the rotating speed of centrifuge is 8000rpm, and centrifugation time is 30min, then take the lower sediment of 200mg and add 100mL of deionized water ultrasonic 12h, obtain the vermiculite nanosheet of concentration 2mg / mL (scanning electron microscope picture is as follows figure 1 As shown, a single-layer structure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com