Heat treatment technology of high-strength flexible wheels used for harmonic rotating speed machine

A high-strength, flexible wheel technology, which is applied in the processing technology of flexible wheels and the heat treatment process of high-strength flexible wheels, can solve the problems of not fully meeting the working conditions of high-performance harmonic speed machines, and is convenient for large-scale promotion, High use value and the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

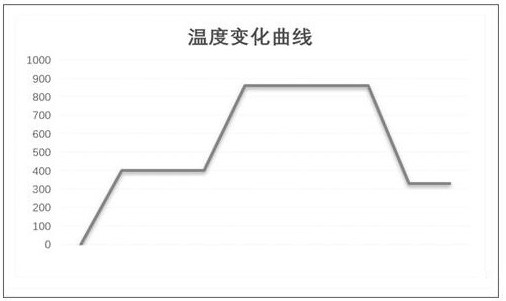

[0025] The present invention proposes a heat treatment process for a high-strength flexible wheel for a harmonic speed machine, which is used for processing a high-strength flexible wheel for a harmonic speed machine. The general temperature change curve is as follows figure 1 shown. The specific plan includes the following steps:

[0026] S1. Loading preparation, pre-cleaning the high-strength flexible wheel workpiece for the harmonic speed machine, and stacking the pre-cleaned high-strength flexible wheel workpiece for the harmonic speed machine in the workpiece tray to complete the loading.

[0027] In this step of operation, it is necessary to clean the surface of the high-strength flexible wheel workpiece for the harmonic speed machine until there is no stain on the surface of the workpiece, and then put the high-strength flexible wheel workpiece for the harmonic speed machine into the workpiece trough, It is ensured that the workpieces of the multiple high-strength flex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com