Method for accurately measuring aperture of air film hole of hot end component coated with thermal barrier coating

A technology of thermal barrier coating and hot-end components, applied in the field of measurement, can solve the problems of harsh service environment, long operating cycle, and high operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

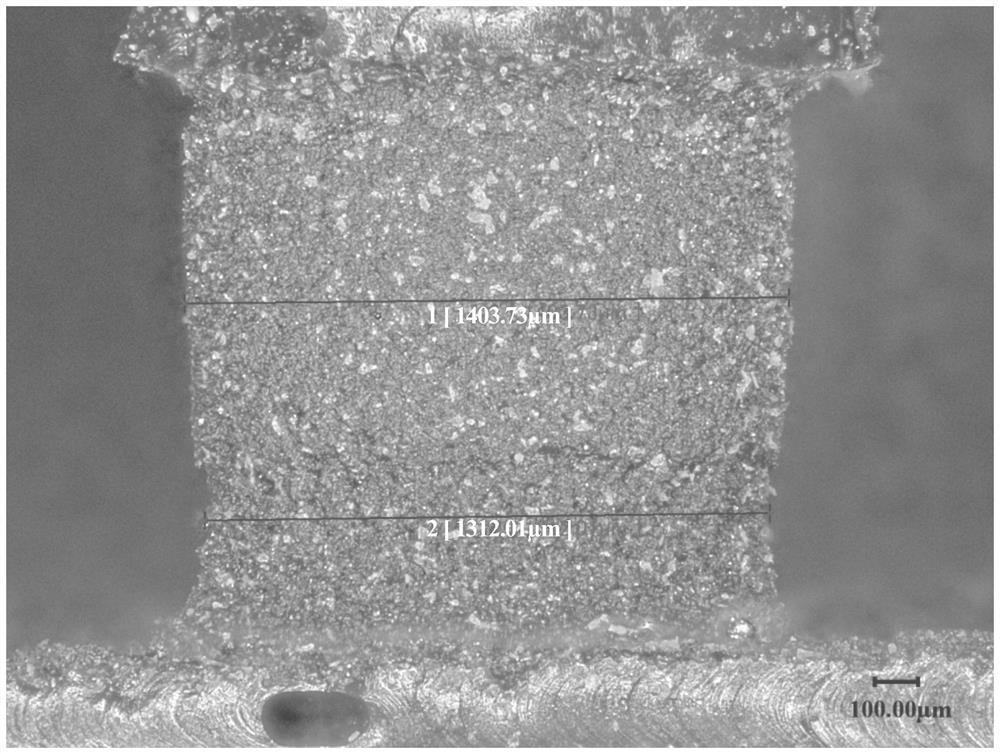

[0025] In this embodiment, the change of the air film hole diameter in the vertical direction of the tile of the hot end component after the thermal barrier coating is applied is measured, and the specific steps are as follows:

[0026] Step 1: Clean the hot-end parts that need to measure the aperture, use compressed air to remove dust on the surface of the thermal barrier coating, and wipe the alloy substrate with alcohol cotton balls, dry it, and set aside;

[0027] Step 2: Squeeze the replicating agent from the thermal barrier coating side into the air film hole to be measured;

[0028] Step 3: Cover a piece of offset paper on the replicating agent, then press down slowly and apply appropriate pressure to make the replicating agent completely enter the air film hole and fully fit with the air film hole without air bubbles or gap;

[0029] Step 4: After standing still for 8 minutes, make the replica agent completely dry and solidify;

[0030] Step 5: Hold the replica with ...

Embodiment 2

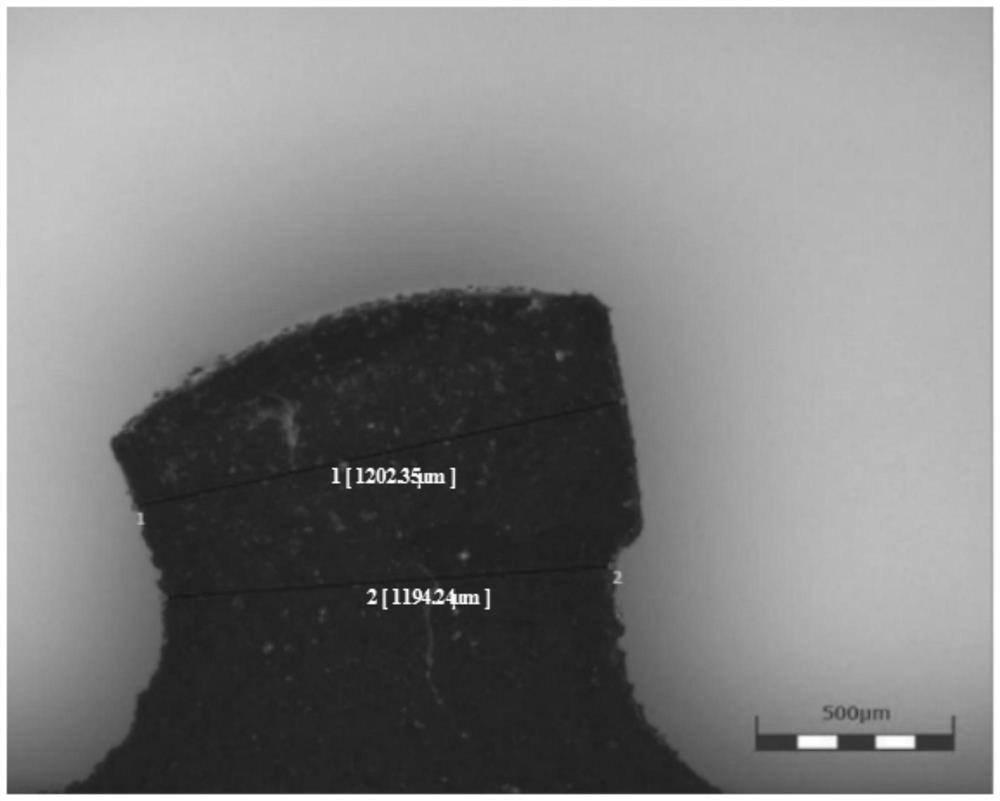

[0034] In this embodiment, the change of the air film hole diameter in the inclined direction of the tile of the hot end component after the thermal barrier coating is applied is measured, and the specific steps are as follows:

[0035] Step 1: Clean the hot-end parts that need to measure the aperture, use compressed air to remove dust on the surface of the thermal barrier coating, and wipe the alloy substrate with alcohol cotton balls, dry it, and set aside;

[0036] Step 2: Squeeze the replicating agent from the thermal barrier coating side into the air film hole to be measured;

[0037] Step 3: Cover a piece of offset paper on the replicating agent, then press down slowly and apply appropriate pressure to make the replicating agent completely enter the air film hole and fully fit with the air film hole without air bubbles or gap;

[0038] Step 4: After standing still for 8 minutes, make the replica agent completely dry and solidify;

[0039] Step 5: Hold the replica with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com