Preparation method of tumor bone cutting edge filler for preventing prosthesis loosening and tumor postoperative recurrence

A stuffer and tumor technology, which is applied in orthopedic implant materials and its preparation, and the implant material and its preparation for prosthesis fixation and inhibition of bone tumor recurrence after surgery, can solve the problems of promoting bone growth at the joint of the prosthesis, Problems such as tumor cells cannot be eliminated, and the effect of reducing the risk of aseptic loosening, solving toxic and side effects, and good implantation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

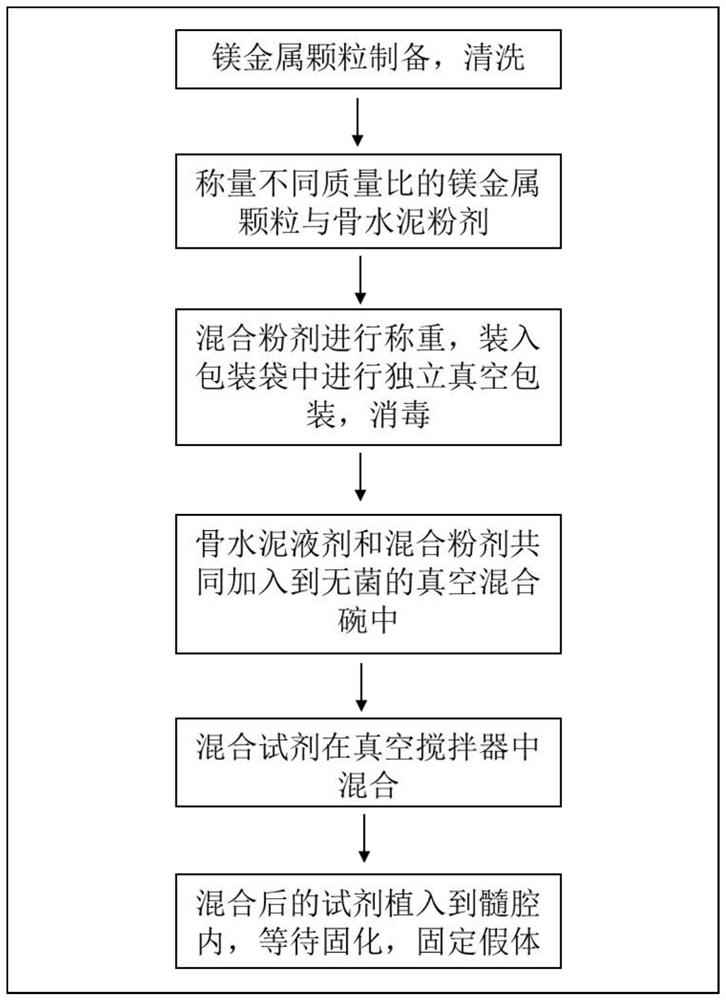

[0026] The preparation method of the tumor bone resection filler for preventing prosthesis loosening and postoperative tumor recurrence is as follows: figure 1 As shown, it includes the following production steps:

[0027] (1) produce metal particles containing magnesium, and carry out cleaning treatment;

[0028] (2) Weigh the quality of bone cement powder and metal particles in proportion;

[0029] (3) the mixed powder weighed in step 2 is packed in the packaging bag and carried out independent vacuum packaging, sterilization;

[0030] (4) When in use, add the mixed powder and bone cement liquid together into a sterile vacuum mixing bowl;

[0031] (5) prevent the magnesium particles from being oxidized in the air, and mix the reagents in a vacuum mixer in step 4;

[0032] (6) After stirring for a certain period of time, implant the mixture of bone cement and magnesium particles into the medullary cavity, wait for curing, and fix the prosthesis.

[0033] Specifically, the...

Embodiment 1

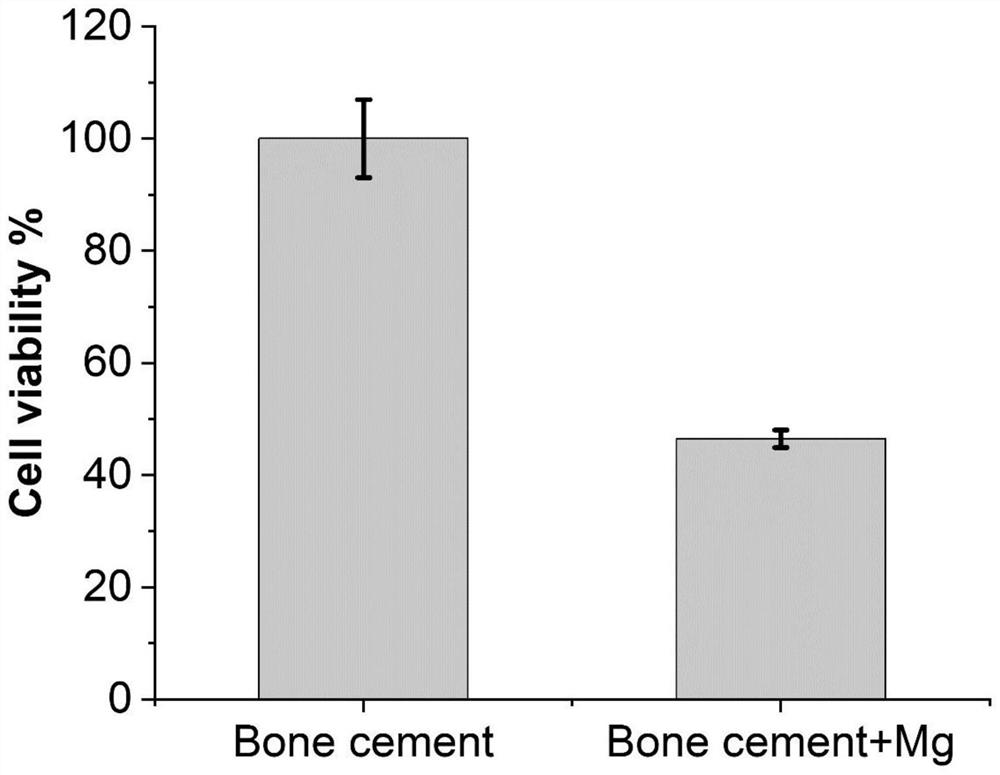

[0039] A method for preparing a tumor bone resection filler for preventing prosthetic loosening and tumor postoperative recurrence, said effect on osteosarcoma cell growth comprising the following steps:

[0040] (1) Prepare high-purity magnesium particles with a diameter of 0.26 mm and a length of 1 mm. The prepared magnesium metal particles were ultrasonically cleaned in n-hexane, acetone, 100% ethanol solution and 70% ethanol solution for 10-25 minutes respectively, and then dried at room temperature.

[0041] (2) The cleaned magnesium metal particles are mixed with bone cement powder, and the mass ratio of mixing is bone cement powder: high-purity magnesium particles is 10:1;

[0042] (3) Take by weighing 3.3 grams of mixed powder, pack it into a packaging bag and carry out vacuum packaging, and irradiate under gamma rays for 15 minutes;

[0043] (4) Pour 1.5 ml of bone cement liquid and mixed powder into a sterile vacuum mixing bowl through a needle, and mix in the vacuu...

Embodiment 2

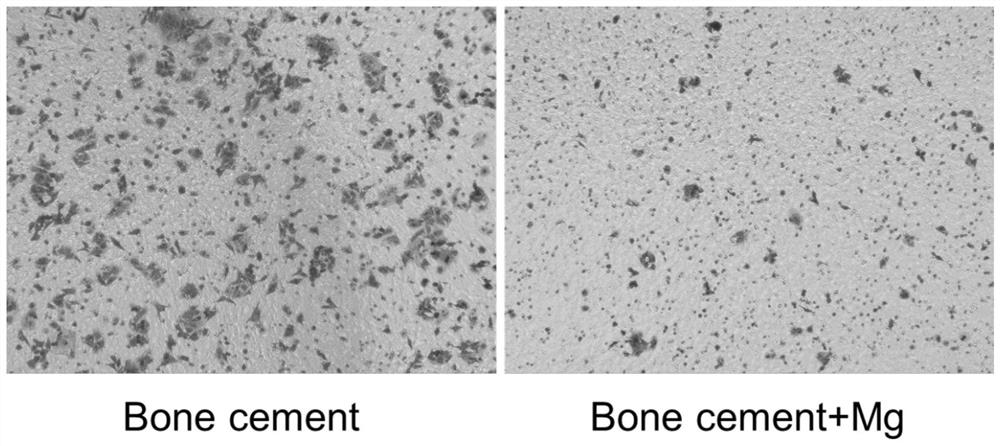

[0054] A method for preparing a tumor bone resection filler for preventing prosthetic loosening and postoperative tumor recurrence, the impact on osteosarcoma cell metastasis comprises the following steps:

[0055] (1) Prepare high-purity magnesium particles with a diameter of 0.26 mm and a length of 1 mm. The prepared magnesium metal particles were ultrasonically cleaned in n-hexane, acetone, 100% ethanol solution and 70% ethanol solution for 10-25 minutes respectively, and then dried at room temperature.

[0056] (2) The cleaned magnesium metal particles are mixed with bone cement powder, and the mass ratio of mixing is bone cement powder: high-purity magnesium particles is 10:1;

[0057] (3) Take by weighing 3.3 grams of mixed powder, pack it into a packaging bag and carry out vacuum packaging, and irradiate under gamma rays for 15 minutes;

[0058] (4) Pour 1.5 ml of bone cement liquid and mixed powder into a sterile vacuum mixing bowl through a needle, and mix in the vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com