Preparation method and application of composition containing fermented rapeseed oil

A technology of rapeseed oil and composition, applied in the field of preparation of fermented rapeseed oil composition, capable of solving environmental and human harmful problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

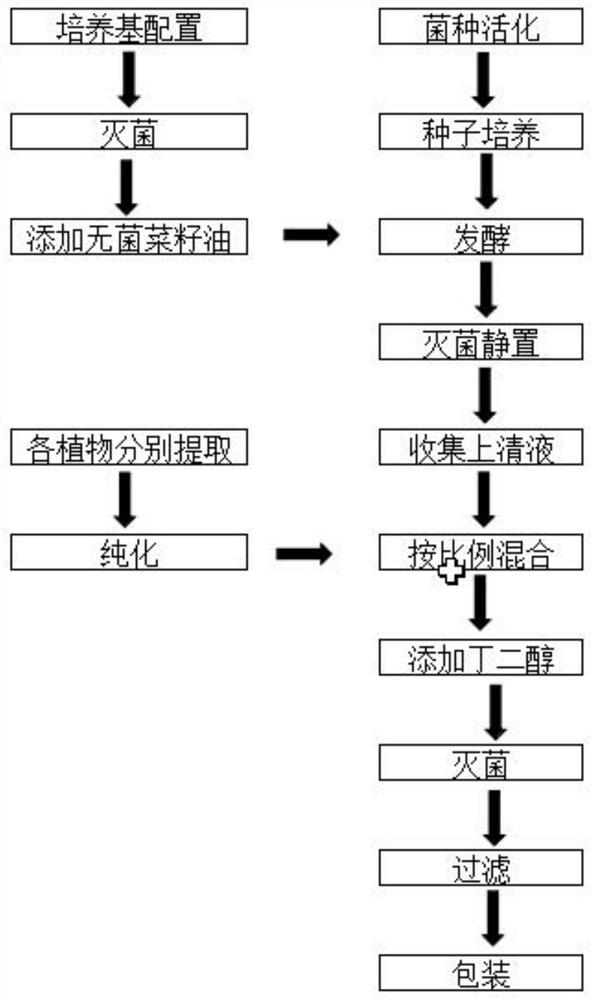

Method used

Image

Examples

Embodiment 1

[0025] 1) The preparation process of fermented rapeseed oil: After the strains are activated, they are cultured on a shaker with YM Broth medium. 0.01% of magnesium sulfate, 0.01% of calcium chloride dihydrate, 0.01% of sodium chloride, 0.01% of peptone, 2% of rapeseed oil, etc. are formulated for fermentation. The fermentation conditions are: pH range 3.5-4.0, fermentation temperature 28 ℃, speed 110rpm, fermentation time 48 hours, ventilation 0.5vvm. After the fermentation is finished, sterilize and stand still to collect the supernatant, and filter to obtain fermented rapeseed oil.

[0026] 2) Extraction of oriental cypress leaves, after crushing the oriental cypress leaves, adopt hot water extraction process, the mass ratio of solid to liquid is: 1:15, the extraction temperature is 75°C, the extraction time is 4 hours, and then the extraction time is 2500r / Centrifuge at a high speed for 1 min, collect the supernatant, concentrate under reduced pressure at 70°C, and separ...

Embodiment 2

[0033] 1) The preparation process of fermented rapeseed oil: After the strains are activated, they are cultured on a shaking table with YM Broth medium. 0.05% of magnesium sulfate, 0.05% of calcium chloride dihydrate, 0.01% of sodium chloride, 0.05% of peptone, 4% of rapeseed oil, etc. are formulated for fermentation. The fermentation conditions are: pH range 3.7-4.3, fermentation temperature 28 ℃, speed 110rpm, fermentation time 48 hours, ventilation 0.5vvm. After the fermentation is finished, sterilize and stand still to collect the supernatant, and filter to obtain fermented rapeseed oil.

[0034]2) Extraction of oriental cypress leaves, after pulverizing the oriental cypress leaves, adopt the hot water extraction process, the mass ratio of solid to liquid is: 1:20, the extraction temperature is 75°C, the extraction time is 4 hours, and then the extraction time is 2800r / Centrifuge at a high speed for 1 min, collect the supernatant, concentrate under reduced pressure at 70...

Embodiment 3

[0041] 1) The preparation process of fermented rapeseed oil: After the strain is activated, it is cultured on a shaking table with YM Broth medium. 0.05% of magnesium sulfate, 0.05% of calcium chloride dihydrate, 0.05% of sodium chloride, 0.1% of peptone, 6% of rapeseed oil, etc. are made into the medium for fermentation. The fermentation conditions are: pH value range 3.5-4.0, fermentation temperature 29 ℃, speed 110rpm, fermentation time 56 hours, ventilation 0.6vvm. After the fermentation is finished, sterilize and stand still to collect the supernatant, and filter to obtain fermented rapeseed oil.

[0042] 2) Extraction of oriental cypress leaves, after pulverizing the oriental cypress leaves, adopt hot water extraction process, the mass ratio of solid to liquid is: 1:25, the extraction temperature is 80°C, the extraction time is 4 hours, and then the extraction time is 3000r / Centrifuge at a high speed for 1 min, collect the supernatant, concentrate under reduced pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com