A kind of method for realizing electrochemical method to remove heavy metal in wastewater

A heavy metal and electrochemical technology, applied in the field of water treatment, can solve the problems of poor pollutant removal effect, achieve the effect of reducing secondary pollution, avoiding introduction, and realizing automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

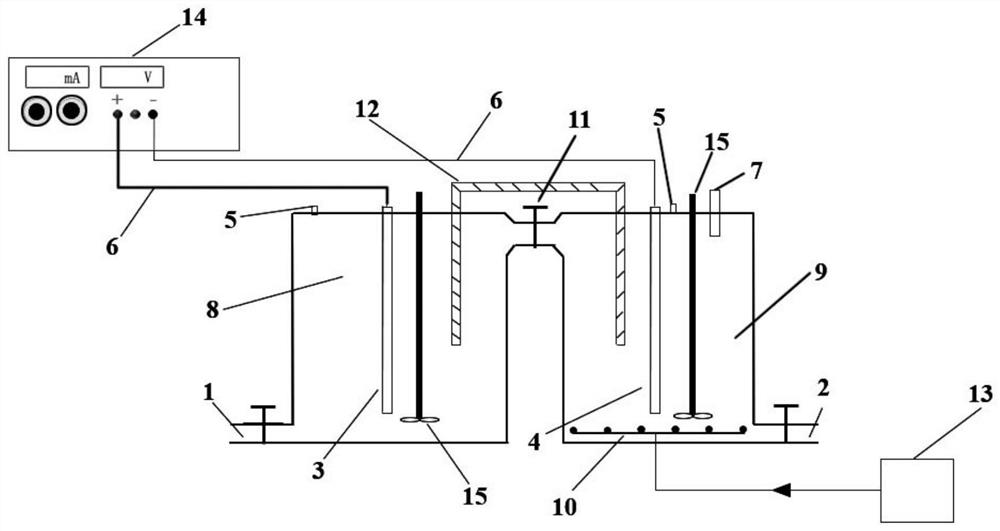

Method used

Image

Examples

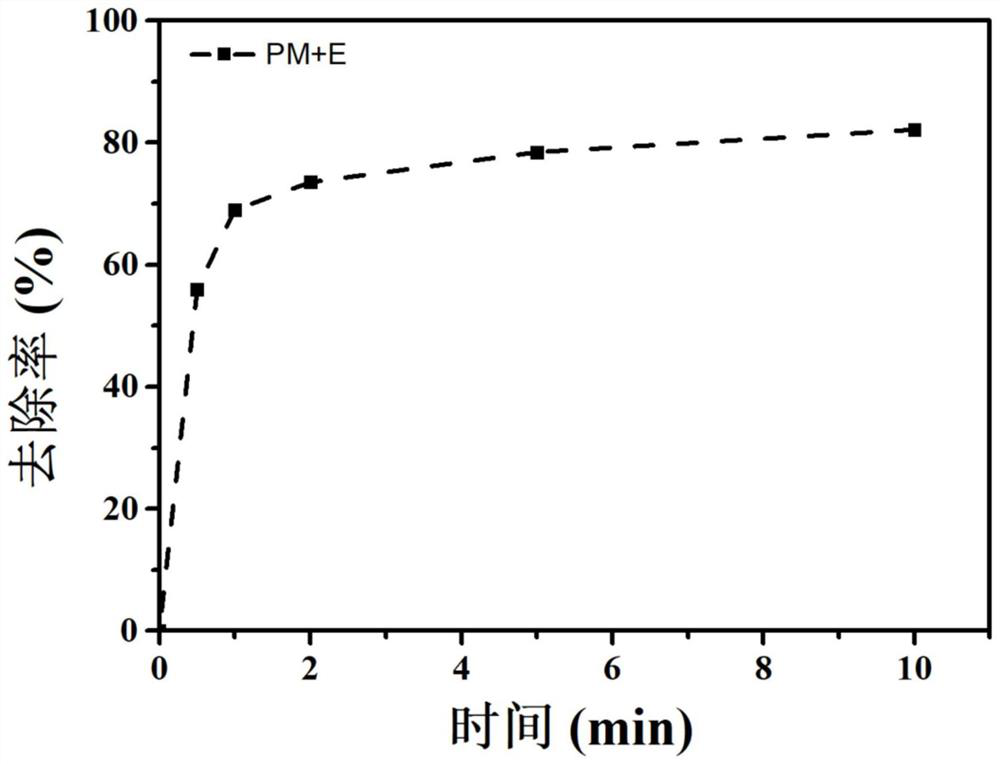

Embodiment 1

[0044] The device for removing heavy metals in wastewater by electrochemical method of the present invention is used to treat chromium-containing wastewater containing 100 mg / L. The steps are as follows: inject the wastewater to be treated into the anode chamber 8, inject water with 0.05M electrolyte into the cathode chamber, and start the direct current Power supply, treatment for 10 minutes, discharge the water sample from the cathode chamber, discharge the wastewater from the anode chamber into the cathode chamber and add 50 μm permanganate, inject the waste water into the anode chamber, start the DC power supply and keep stirring, and constantly aerate to maintain high manganese The salt concentration is 50μm, the electrification current is set to 50mA, and after electrification for 10min, it settles for 5h and discharges the treated sewage. In this example, the permanganate is potassium permanganate, and potassium permanganate is completely dissolved with an appropriate am...

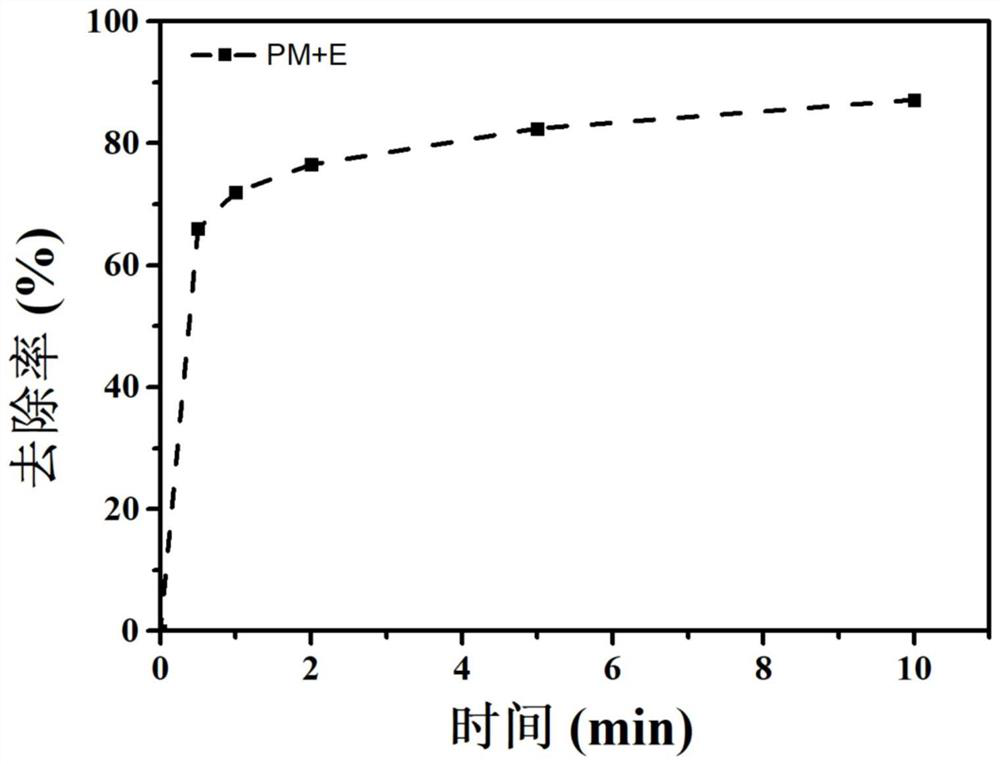

Embodiment 2

[0047] The device for removing heavy metals in wastewater by electrochemical method of the present invention is used to treat chromium-containing wastewater containing 100mg / L. The steps are as follows: inject the wastewater to be treated into the anode chamber 8, inject water with 0.05M electrolyte into the cathode chamber 9, and start the process. DC power supply, process for 10min, discharge the water sample from the cathode chamber 9, discharge the wastewater from the anode chamber 8 into the cathode chamber 9 and add 100 μm permanganate, inject the wastewater into the anode chamber 8, start the DC power supply 14 and keep stirring , continuously aerate, keep the concentration of permanganate at 100μm and the energizing current at 100mA, after energizing for 10min, settle for 5h and discharge the treated sewage. In this example, the permanganate is potassium permanganate, and the potassium permanganate is completely dissolved with an appropriate amount of water, and then ad...

Embodiment 3

[0050] The device for removing heavy metals in wastewater by electrochemical method of the present invention is used to treat chromium-containing wastewater containing 100mg / L. The steps are as follows: inject wastewater to be treated into anode chamber 8, inject water with 0.05M electrolyte into cathode chamber 9, and start the process. DC power supply, treatment for 10 minutes, discharge the water sample from the cathode chamber, drain the wastewater from the anode chamber into the cathode chamber and add 50 μM permanganate, inject the waste water into the anode chamber, start the DC power supply and keep stirring, constantly aerating, to maintain a high temperature. The manganate concentration is 100μm and the energizing current is 200mA. After energizing for 20 minutes, it settles for 5 hours and discharges the treated sewage.

[0051] In this example, the permanganate is potassium permanganate, and the potassium permanganate is completely dissolved with an appropriate amou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com