Aggregate for preparing cement-based ceramic binder and preparation method thereof

A ceramic binder, cement-based technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of inability to achieve sustainable development, lack of resources, rising costs, etc., and achieve sustainable development. , The overall method is simple, reducing the effect of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The aggregate for preparing cement-based ceramic binder according to the present invention, the aggregate is any combination of any two or more particle sizes in coconut palm silk particles with a particle size of 0.5-2 mm; the coconut palm Silk granules are cut from coconut palm silk that has been sequentially processed through the following steps:

[0061] (1) Preprocessing

[0062] (1) Wash the coconut palm silk until the water is clear;

[0063] (2) Take out the washed coconut palm silk, and dry it in an oven at 70°C for 2h;

[0064] (3) take out the coconut palm silk after drying, and the air temperature is lowered to 23 ℃, namely obtains clean coconut palm silk;

[0065] (2) Chemical treatment

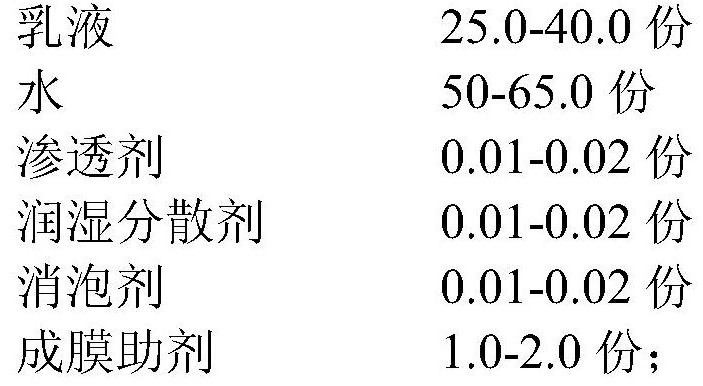

[0066] The clean coconut palm silk is completely immersed in the medicament for 24h, and the medicament is mainly prepared from the following components according to the following ratios by weight:

[0067]

[0068] (3) Physical treatment

[0069] The coconut palm ...

Embodiment 2

[0091] The aggregate for preparing cement-based ceramic binder according to the present invention, the aggregate is any combination of any two or more particle sizes in coconut palm silk particles with a particle size of 0.5-2 mm; the coconut palm Silk granules are cut from coconut palm silk that has been sequentially processed through the following steps:

[0092] (1) Preprocessing

[0093] (1) Wash the coconut palm silk until the water is clear;

[0094] (2) Take out the washed coconut palm silk, and dry it in an oven at 65°C for 2.5h;

[0095] (3) take out the coconut palm silk after drying, and the air temperature is lowered to 22 ℃, namely obtains clean coconut palm silk;

[0096] (2) Chemical treatment

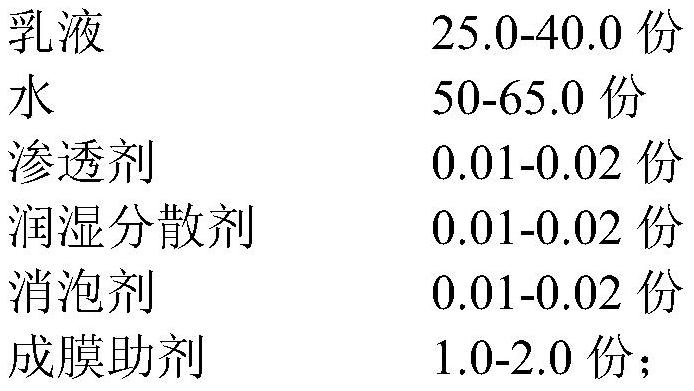

[0097] The clean coconut palm silk was completely immersed in the medicament for 48h, and the medicament was mainly prepared from the following components according to the following ratios by weight:

[0098]

[0099] (3) Physical treatment

[0100] The coconut p...

Embodiment 3

[0122] The aggregate for preparing cement-based ceramic binder according to the present invention, the aggregate is any combination of any two or more particle sizes in coconut palm silk particles with a particle size of 0.5-2 mm; the coconut palm Silk granules are cut from coconut palm silk that has been sequentially processed through the following steps:

[0123] (1) Preprocessing

[0124] (1) Wash the coconut palm silk until the water is clear;

[0125] (2) Take out the washed coconut palm silk, and dry it in an oven at 75°C for 1.5h;

[0126] (3) take out the coconut palm silk after drying, and the air temperature is lowered to 24 ℃, namely obtains clean coconut palm silk;

[0127] (2) Chemical treatment

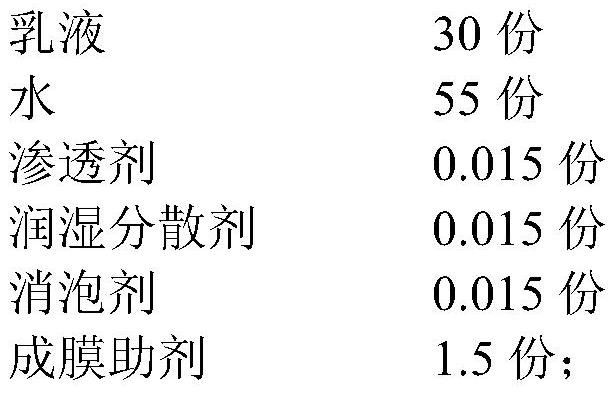

[0128] The clean coconut palm silk is completely immersed in the medicament for 36h, and the medicament is mainly prepared from the following components according to the following ratios by weight:

[0129]

[0130] (3) Physical treatment

[0131] The coconut palm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com