Synthesis method of low-carbon sodium alcoholate

A synthesis method and technology for low-carbon alcohols, applied in the preparation of alcohol metal, organic chemistry, biofuels, etc., can solve the problems of low production efficiency, process danger, large heat release, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

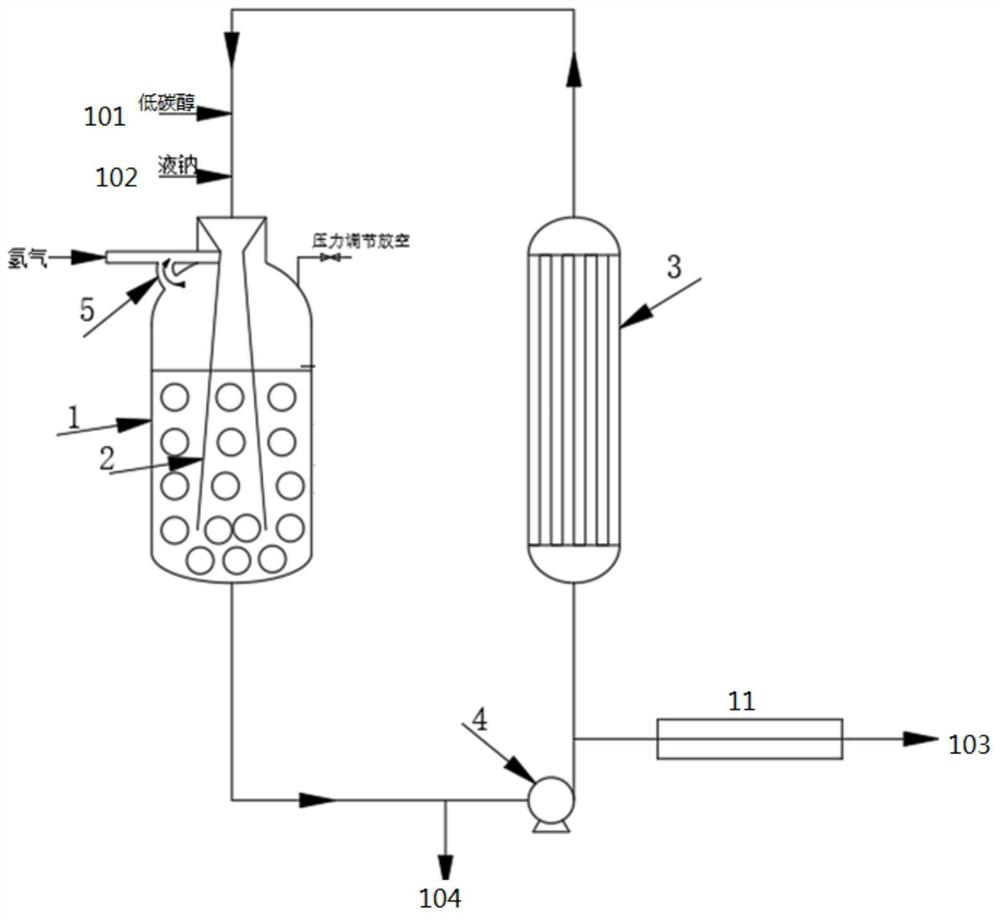

[0047] Towards figure 1 The shown loop reactor (reactor volume 5L) is fed into the reaction kettle with methanol at room temperature with 40% of the kettle volume through the low-carbon alcohol feed port 101, and hydrogen gas is introduced into the reaction system through the air inlet until the system pressure is 1 MPa, and the opening The circulation pump 4 makes the liquid in the kettle flow slowly, and the gas is emptied, and the air in the loop reactor is replaced 6 times. After the last replacement, keep the pressure of the reaction system at 0.3MPa, and raise the temperature to 70°C (about 10 minutes during the heating process), adjust the circulating pump 4 to increase the liquid flow rate to a liquid linear velocity at the nozzle of 60m / s, and maintain the system circulation.

[0048] Towards figure 1 The shown loop reactor (reactor volume 5L) feeds liquid sodium into the reactor through the liquid sodium feed port 102 (filling process 1.5h), and the total amount of ...

Embodiment 2

[0052] Preparation example of sodium methoxide

[0053] Towards figure 1 The shown loop reactor (reactor volume 5L) is fed into the reaction kettle with methanol at room temperature with 40% of the kettle volume through the low-carbon alcohol feed port 101, and hydrogen gas is introduced into the reaction system through the air inlet until the system pressure is 1 MPa, and the opening The circulation pump 4 makes the liquid in the kettle flow slowly, and the gas is emptied, and the air in the loop reactor is replaced 6 times. After the last replacement, keep the pressure of the reaction system at 0.3MPa, and raise the temperature to 70°C (about 10 minutes during the heating process), adjust the circulating pump 4 to increase the liquid flow rate to a liquid linear velocity at the nozzle of 60m / s, and maintain the system circulation.

[0054] Towards figure 1 The shown loop reactor (reactor volume 5L) feeds liquid sodium into the reactor through the liquid sodium feed port 10...

Embodiment 3

[0058] Preparation example of sodium methoxide

[0059] Towards figure 1 The shown loop reactor (reactor volume 5L) is fed into the reaction kettle with methanol at room temperature with 40% of the kettle volume through the low-carbon alcohol feed port 101, and hydrogen gas is introduced into the reaction system through the air inlet until the system pressure is 1 MPa, and the opening The circulation pump 4 makes the liquid in the kettle flow slowly, and the gas is emptied, and the air in the loop reactor is replaced 6 times. After the last replacement, keep the pressure of the reaction system at 0.3MPa, and raise the temperature to 70°C (about 10 minutes during the heating process), adjust the circulating pump 4 to increase the liquid flow rate to a liquid linear velocity at the nozzle of 60m / s, and maintain the system circulation.

[0060] Towards figure 1 The shown loop reactor (reactor volume 5L) feeds liquid sodium into the reactor through the liquid sodium feed port 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com