Self-emulsifying softening agent and preparation method thereof

A softener and self-emulsifying technology, applied in the field of self-emulsifying softener and its preparation, can solve the problems of difficult production control and easy gelation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] In a preferred embodiment, the present invention provides a method for preparing a self-emulsifying softener comprising the steps of:

[0053] 1) The siloxane-based monomer, a urethane surfactant monomer, carboxylic monomer, and deionized water added to the kettle, stirring emulsification 1-2h 40-60 ℃;

[0054] 2) heating to 65-85 deg.] C, was added dropwise an aqueous solution of ammonium persulfate to initiate polymerization;

[0055] 3) heating to 80-95 ℃, incubated 1-5h, prepared from the emulsified softener.

[0056] 1) In the above step, with respect to 100 parts by weight of the total siloxane monomer, a urethane surfactant monomer, carboxylic monomer, and deionized water, the siloxane-based monomer is 10- 15 parts by weight, the urethane surfactant monomer is 10-20 parts by weight of the carboxylic acid monomer is 1-5 parts by weight, the siloxane-based monomer is preferably 11-14 parts by weight, preferably, the surfactant is a polyurethane-based monomer is 13-16 p...

Embodiment 1

[0084] The single-ended 13g vinyl silicone oil SiVans MV 500 (viscosity 500 cSt, a vinyl content of 0.32 mol%, commercially available from Silicon Technology Materials Vance Nantong Co.), (Ⅴ) polyurethane surfactants 15g monomer (m is 44, raw materials for TDI, PEG2000, maleic anhydride, triethylamine, prepared with reference papers published: SONG Zhi Chao, HU mold, Liu in the United States, "preparation and properties of the polymerizable urethane-type surfactant"), 2g allylmalonic acid 70g deionized water was added and the reactor was stirred for 1.5 h 40 ℃ emulsion; heated to 70 ℃, ammonium persulfate aqueous solution was added dropwise, initiate a polymerization reaction; warmed to 85 ℃, heat 3h, was prepared from the emulsified softener .

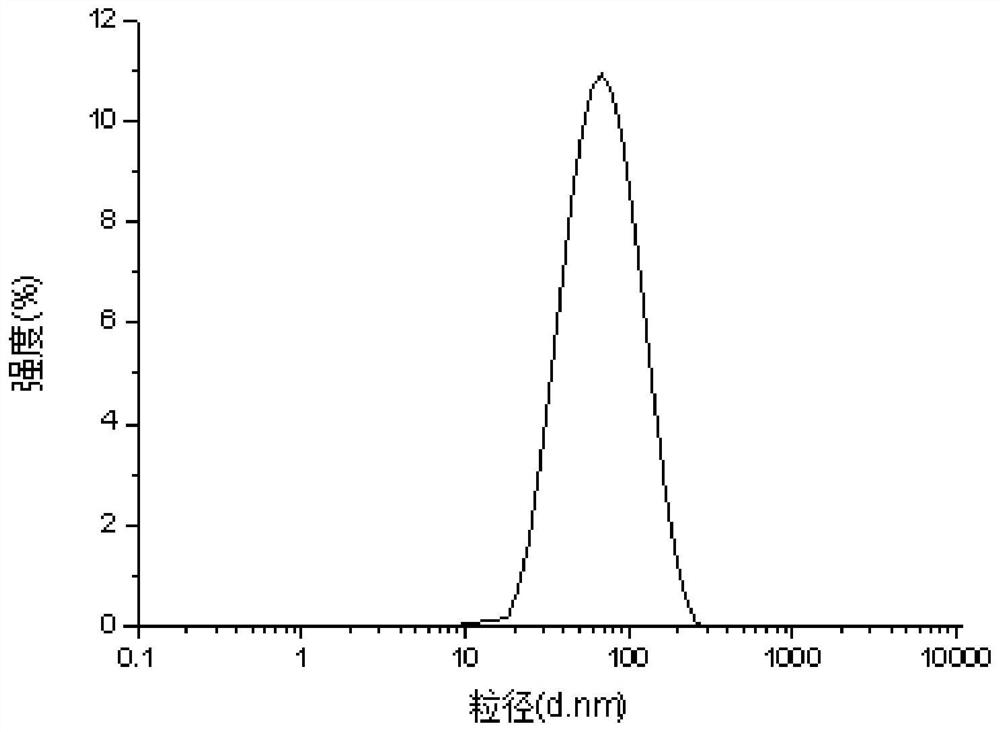

[0085] A heavy emulsion softener from the average molecular weight of 44,000. See size distribution figure 1 The average particle diameter (d.nm) of 57.83, PDI was 0.240. Stability Table 1, in Table 2 the measurement application performan...

Embodiment 2

[0087] The single-ended 14g vinyl silicone oil SiVans MV 500 (viscosity 500 cSt, a vinyl content of 0.32 mol%, commercially available from Silicon Technology Materials Vance Nantong Co.), (Ⅴ) polyurethane surfactants 13g monomer (m is 18, raw materials for TDI, PEG800, maleic anhydride, triethylamine, prepared with reference papers published: SONG Zhi Chao, HU mold, Liu in the United States, "preparation and properties of the polymerizable urethane-type surfactant"), 3G methacrylic acid and 70g deionized water was added reactor, stirred for 1.5 h 45 ℃ emulsion; heated to 75 ℃, ammonium persulfate aqueous solution was added dropwise, initiate a polymerization reaction; warmed to 85 ℃, heat 4h, was prepared from the emulsified softener.

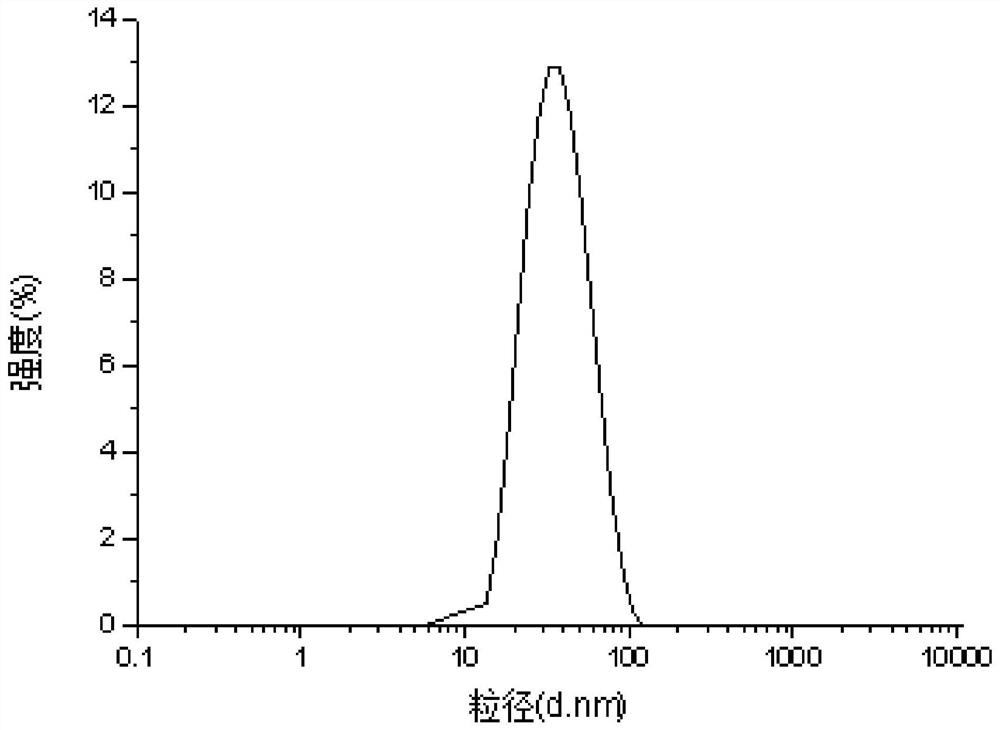

[0088] 2 heavy emulsion softener from the average molecular weight of 61,000. See size distribution figure 2 The average particle diameter (d.nm) of 33.03, PDI was 0.157. Stability Table 1, in Table 2 the measurement application performance textile...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com