Bionic composite hydrogel as well as preparation method and application thereof

A composite hydrogel and hydrogel technology, applied in tissue regeneration, prosthesis, medical science, etc., can solve problems such as complex preparation process, low toughness, and low hydrogel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a kind of preparation method of biomimetic composite hydrogel, comprises the following steps:

[0035] (1) Provide composite hydrogel;

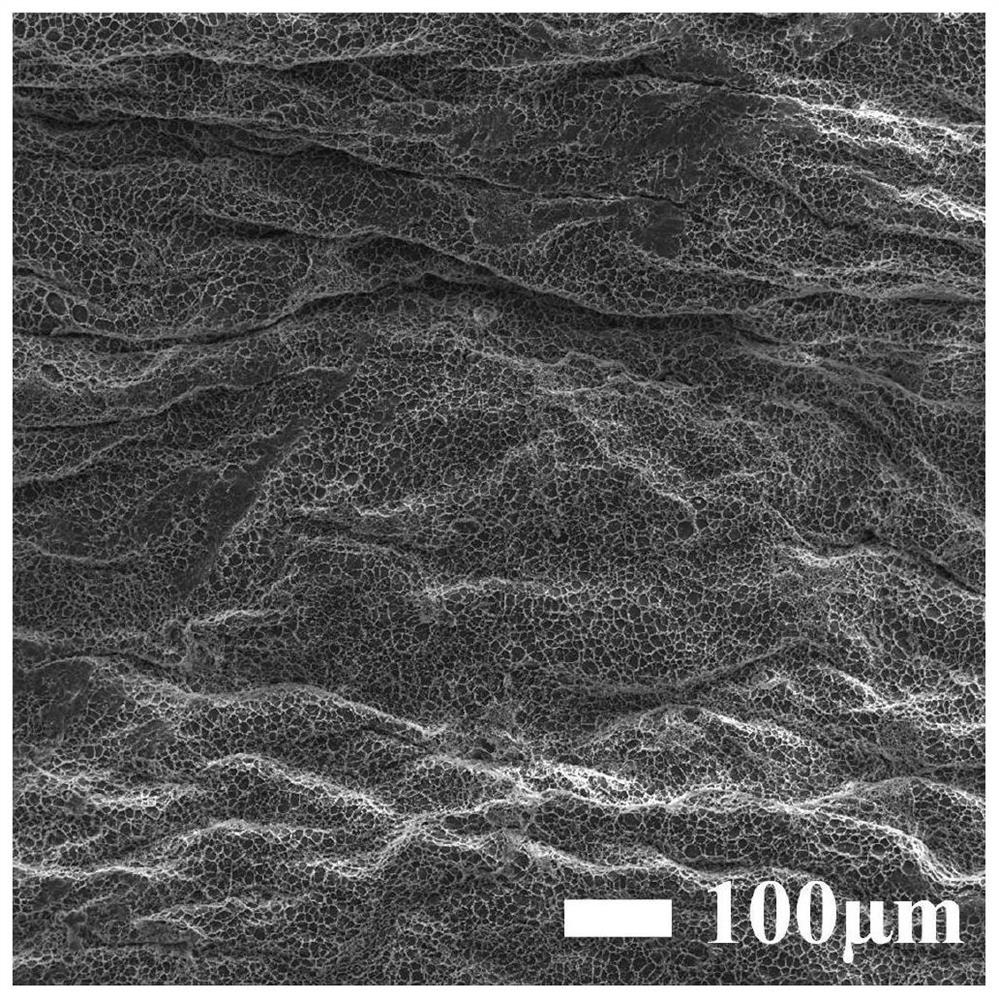

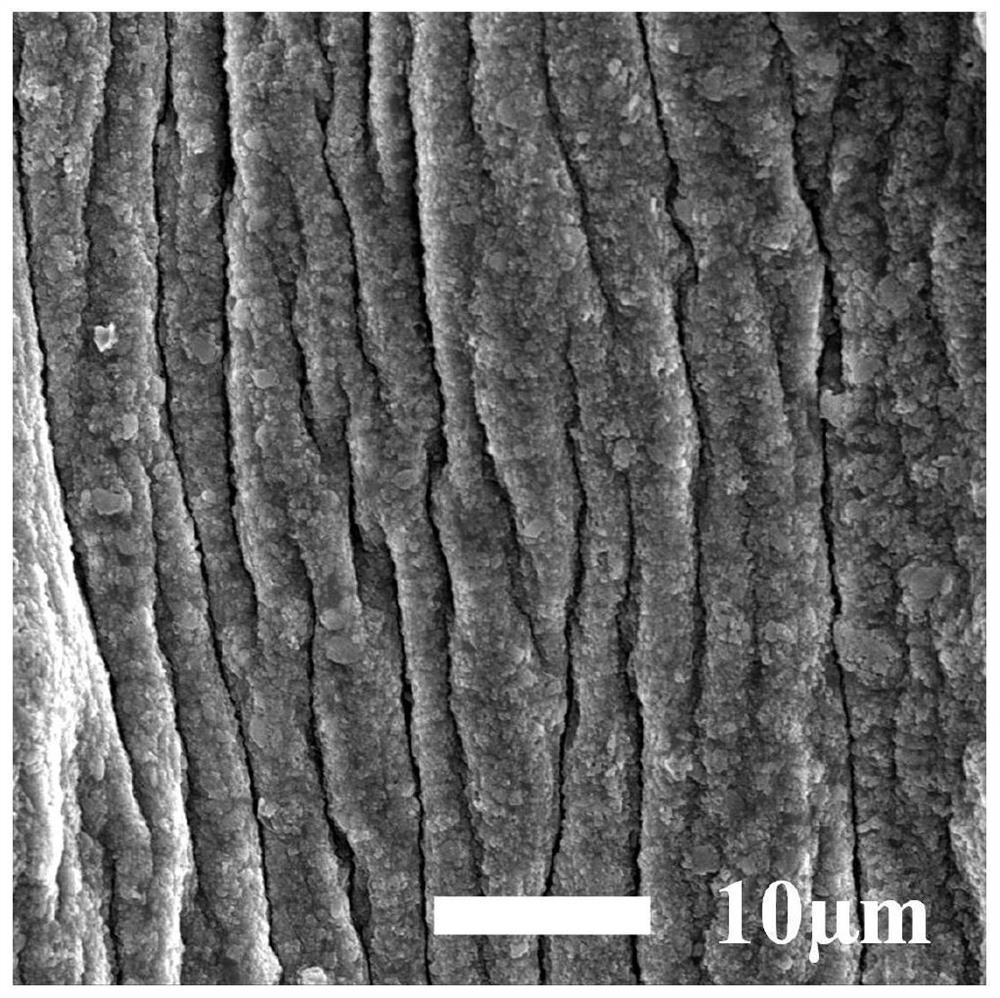

[0036] (2) The composite hydrogel obtained in the step (1) is sequentially subjected to confinement drying and swelling in air, and then soaked in a saturated NaCl solution to obtain a biomimetic composite hydrogel.

[0037] The present invention provides composite hydrogels. In the present invention, the composite hydrogel preferably includes PVA / CMC-Fe 3+ Composite hydrogel, or PVA / cellulose derivative-Fe 3+ Double network composite hydrogels. The present invention is to described PVA / CMC-Fe 3+ Double network composite hydrogel or PVA / cellulose derivative-Fe 3+ The preparation method of the double-network composite hydrogel is not particularly limited, and a preparation method well known to those skilled in the art can be used.

[0038] In the present invention, the PVA / CMC-Fe 3+ The preparation method o...

Embodiment 1

[0072] (1) Dissolve 3.4g of PVA in 20mL of deionized water, 0.72g of CMC in 9mL of deionized water, and accelerate the stirring in a heat-collecting magnetic stirring bath at 92°C; after both are completely dissolved, add the CMC solution to into the PVA solution, stirred at 92°C for 20 minutes to make it evenly mixed; added dropwise hydrochloric acid with a volume fraction of 30%, and adjusted the pH of the solution to 2; put the obtained solution in an ice-water bath until the temperature dropped to 0°C, Add 1 mL of 5% glutaraldehyde and stir rapidly to ensure that the solution is well mixed. Pour the obtained solution into a polypropylene mold and place it in a constant temperature water bath at 50°C for 0.5h to form a chemically cross-linked PVA / CMC single network hydrogel, referred to as PVA / CMC-SN hydrogel; among them, CMC and The mass ratio of PVA is 0.21:1;

[0073] (2) PVA / CMC-SN hydrogel in 0.1mol / L Fe(NO 3 )3 9H 2 Soak in O solution for 24 hours. Subsequently, t...

Embodiment 2

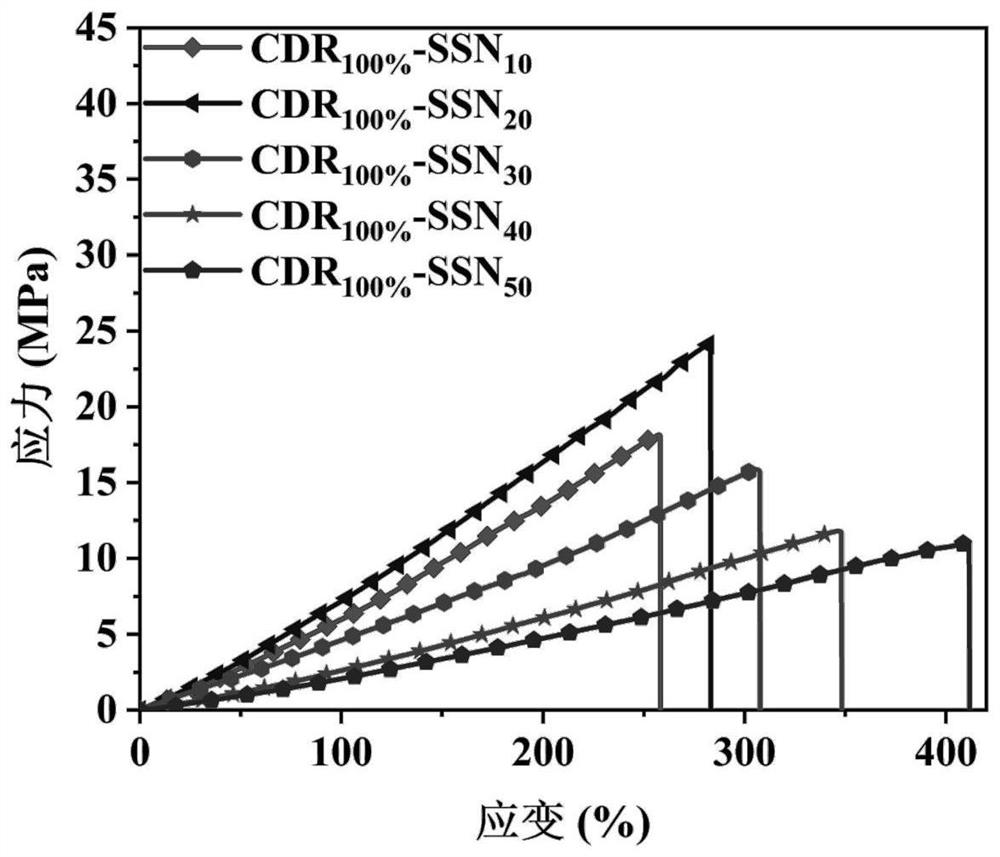

[0078] The difference from Example 1 is that the time for the swollen hydrogel in step (3) to be soaked in a saturated NaCl solution is 20 minutes, and the remaining steps are the same as in Example 1 to obtain a biomimetic composite hydrogel, referred to as CDR 100% -SSN 20 Hydrogels.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com