Detergent for gasoline car as well as preparation device and method of cleaning agent

A technology for preparing devices and detergents, which is applied in mechanical equipment, petroleum industry, fuel additives, etc., and can solve problems such as valve clogging, engine corrosion, and engine damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

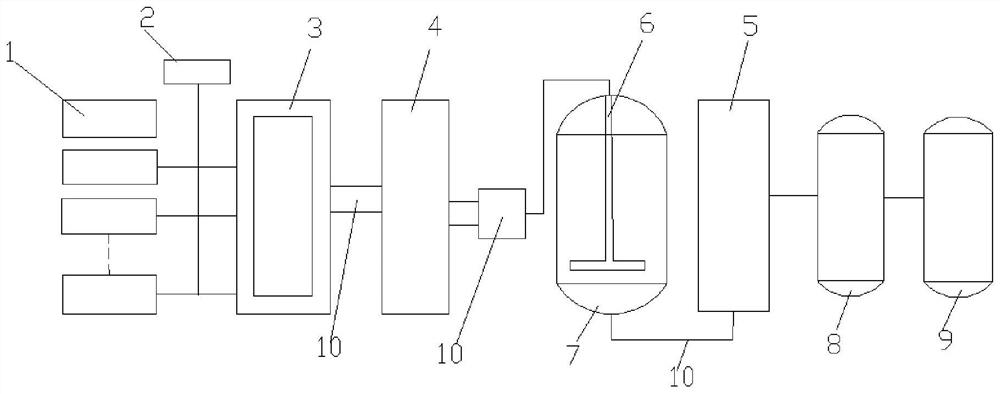

Method used

Image

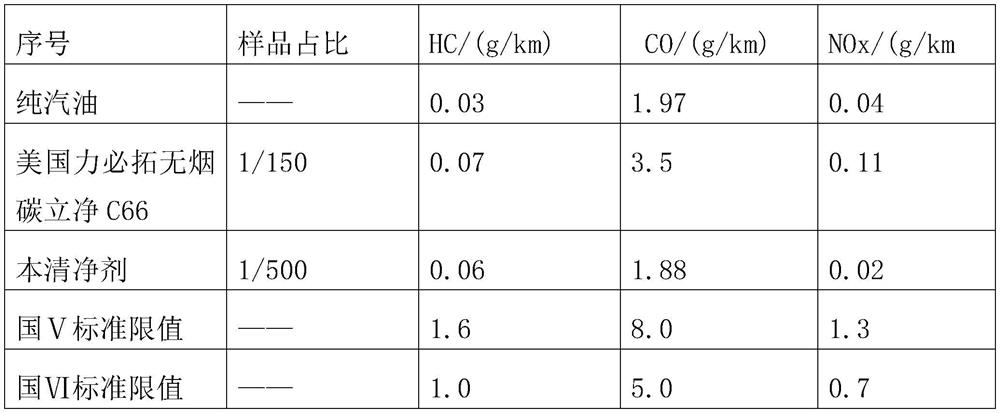

Examples

Embodiment 1

[0056] A kind of preparation method of above-mentioned detergent for gasoline vehicle, comprises the following steps successively:

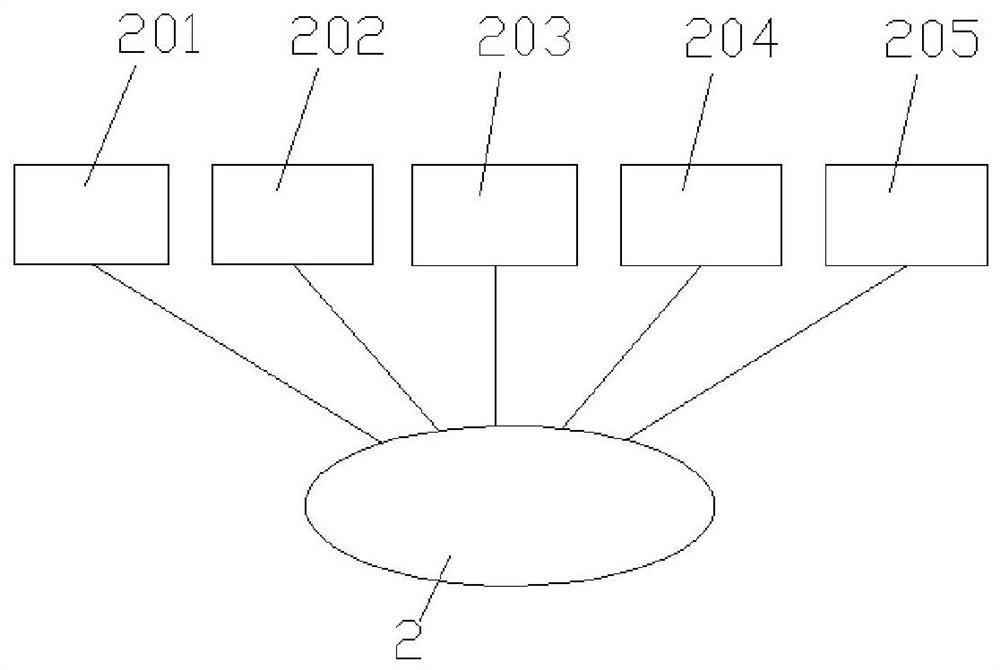

[0057] (1) Feeding preparation: set the proportioning amount of basic auxiliary materials and blending materials on the meter 201 of the automatic batching quantitative delivery console 2, and set the preheating temperature, primary filtration time, the rotating speed of the mixer, the reaction time of the reactor, Base tank standing time;

[0058] Put the basic auxiliary materials into the auxiliary material tank 1 and the blending material into the blending tank 9 according to the proportion, and then turn on the preheating switch to preheat the OP-10. The preheating temperature is 45°C until the preheating indicator light is on. Indicates that preheating is complete;

[0059] (2) primary filter mixing: start the pumping switch 202, pump the basic auxiliary materials to the primary filter 4 according to the ratio for primary filter mixing, and...

Embodiment 2

[0064] A kind of preparation method of above-mentioned detergent for gasoline vehicle, comprises the following steps successively:

[0065] (1) Feeding preparation: set the proportioning amount of basic auxiliary materials and blending materials on the meter 201 of the automatic batching quantitative delivery console 2, and set the preheating temperature, primary filtration time, the rotating speed of the mixer, the reaction time of the reactor, Base tank standing time;

[0066] Put the basic auxiliary materials into the auxiliary material tank 1 and the blending material into the blending tank 9 according to the ratio, and then turn on the preheating switch to preheat the OP-10. The preheating temperature is 48°C until the preheating indicator light is on. Indicates that preheating is complete;

[0067] (2) primary filter mixing: start the pumping switch 202, pump the basic auxiliary materials to the primary filter 4 according to the ratio for primary filter mixing, and the ...

Embodiment 3

[0072] A kind of preparation method of above-mentioned detergent for gasoline vehicle, comprises the following steps successively:

[0073] (1) Feeding preparation: set the proportioning amount of basic auxiliary materials and blending materials on the meter 201 of the automatic batching quantitative delivery console 2, and set the preheating temperature, primary filtration time, the rotating speed of the mixer, the reaction time of the reactor, Base tank standing time;

[0074] And put the basic auxiliary materials into the auxiliary material tank 1 and the blending material into the blending tank 9 according to the ratio, and then turn on the preheating switch to preheat the OP-10. The preheating temperature is 50°C until the preheating indicator light is on. Indicates that preheating is complete;

[0075] (2) primary filter mixing: start the pumping switch, pump the basic auxiliary materials to the primary filter according to the ratio for primary filter mixing, and the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com