Preparation method of copper-based thick-wall niobium-based superconducting cavity

A superconducting cavity and copper-based technology, which is applied in the field of superconducting, can solve the problems that cannot be widely used, the grain size is small, and the RF performance of copper-niobium sputtering film cavity cannot reach that of pure niobium superconducting cavity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

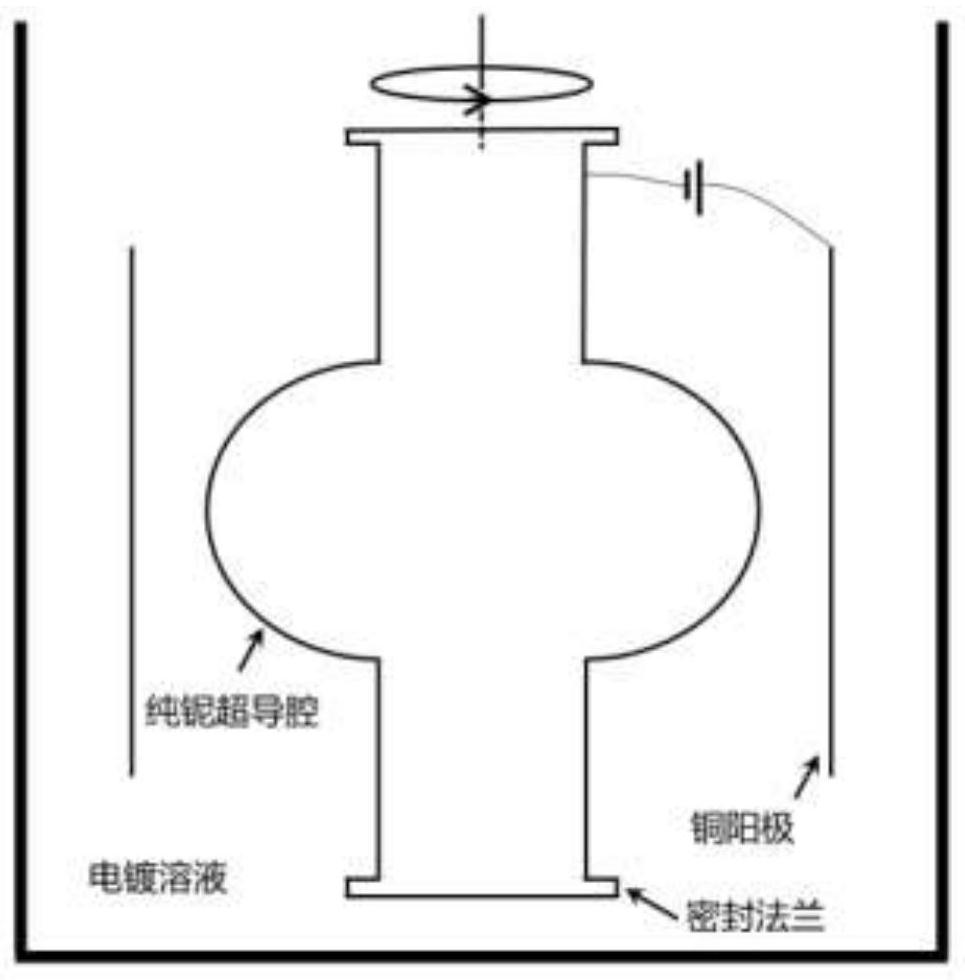

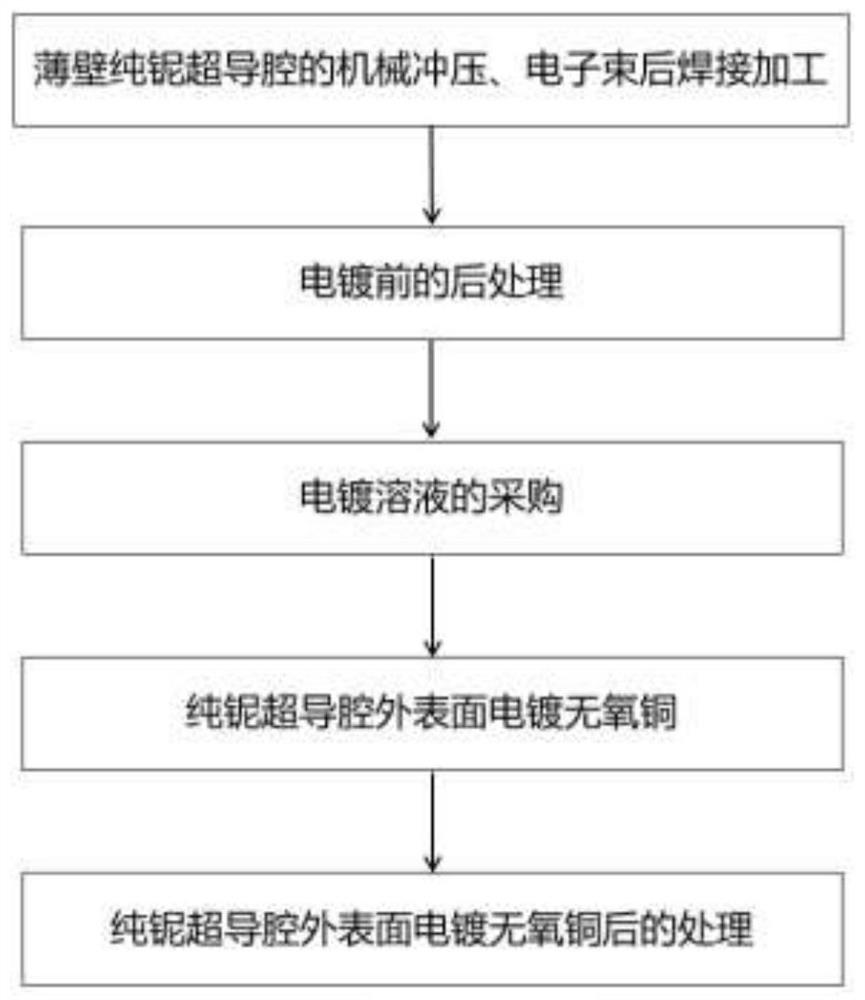

[0049] Example 1. Preparation of copper-based thick-walled pure niobium superconducting cavity by electroplating oxygen-free copper on the outer surface

[0050] 1. Mechanical stamping and post-electron beam welding of thin-walled pure niobium superconducting cavities are mainly to obtain substrate niobium cavities for copper plating on the outer surface. The main process includes:

[0051] ① Using high-purity niobium materials with RRR>300 and a thickness of 1.5-2.5mm, the thin-walled superconducting cavity parts and bundle tubes of the required shape are produced through stamping dies. The use of high-purity niobium plates of 1.5-2.5mm is to reduce the The wall thickness of the guide cavity is used to reduce the thermal resistance of the niobium material, and the niobium-titanium alloy material is used to process the flange that is connected to the bundle tube with a lathe;

[0052] ②Use an ultrasonic cleaning device to perform ultrasonic cleaning on the parts completed in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com