Light and small optical fiber gyroscope with good environmental adaptability

A fiber optic gyroscope technology with good environmental adaptability, applied in Sagnac effect gyroscopes, gyroscope/steering sensing equipment, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

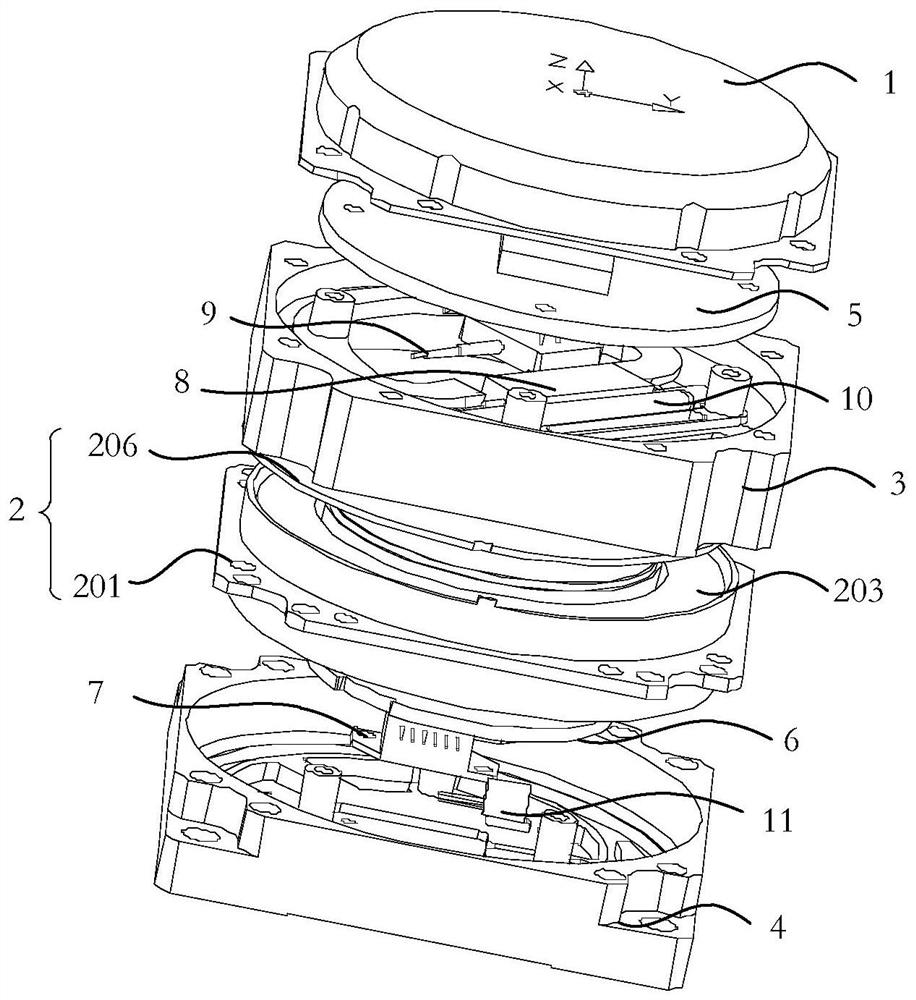

[0099] In this embodiment, a light and small fiber optic gyroscope with good environmental adaptability, the upper end cover 1 is 8g;

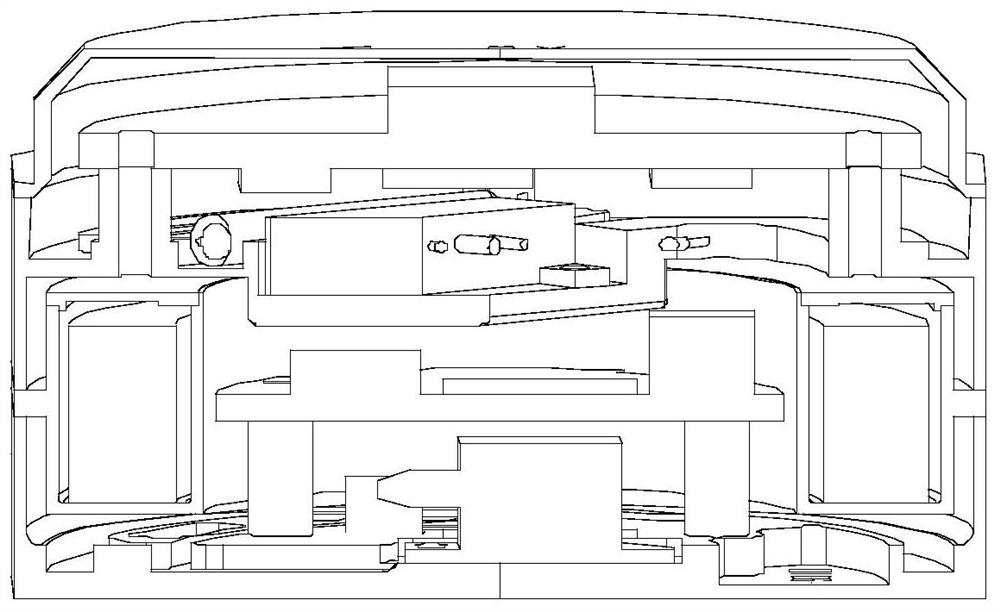

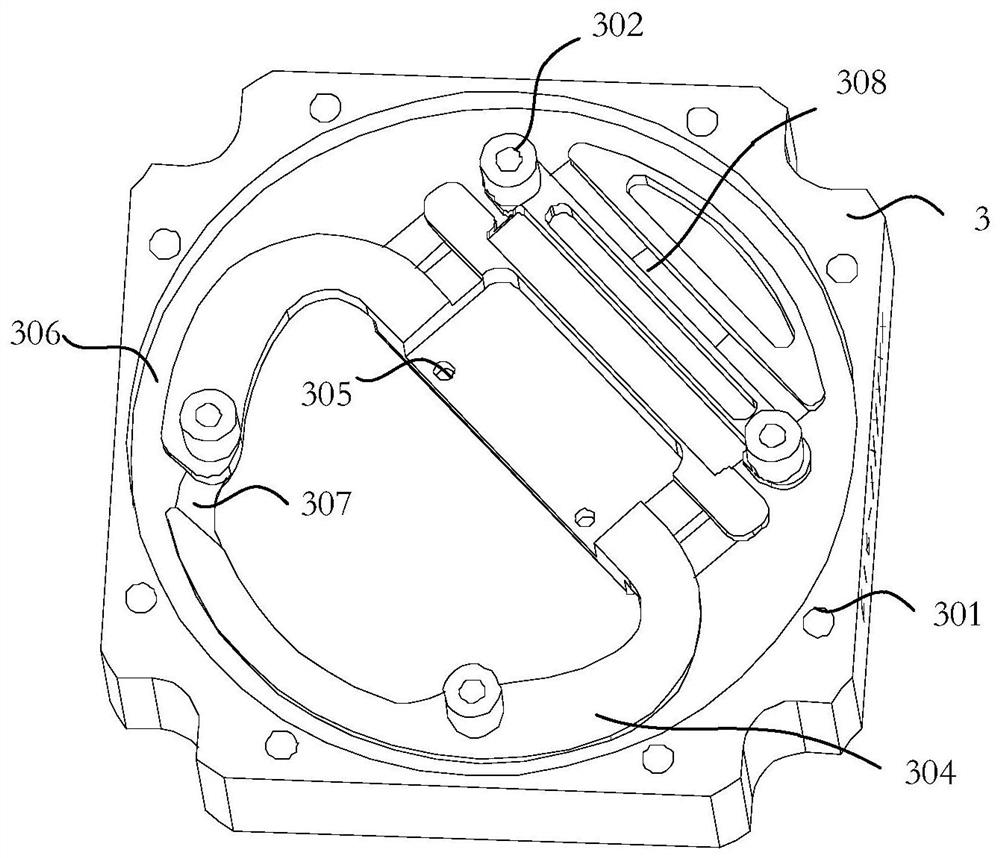

[0100] In the fiber optic ring installation assembly 2, the fiber optic ring upper cover 206 is 8g, the fiber optic ring base 201 is 38g, and the fiber optic ring assembly is made of iron-nickel alloy 1J85, which can meet the magnetic shielding requirements of the fiber optic gyroscope; Figure 5 As shown, the optical fiber ring adopts a four-level symmetrical winding method. The inner diameter of the optical fiber ring is not less than 40mm, the outer diameter is not greater than 53mm, and the height is not greater than 11mm; the wall thickness of the optical fiber ring base is 0.5-0.6mm, and the weight of the structural parts is only 38g.

[0101] The mounting base 4 is 33g; the mounting flange 3 is 26g; the total weight of the fiber optic gyroscope is 200g.

[0102] In this embodiment, the volume of the fiber optic gyroscope is 60mm×60mm×30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com