Process chamber with water vapor evaporation system

A technology of water vapor evaporation and process chamber, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve problems such as wasting production capacity, damaging the process tube chamber, and increasing the workload of staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

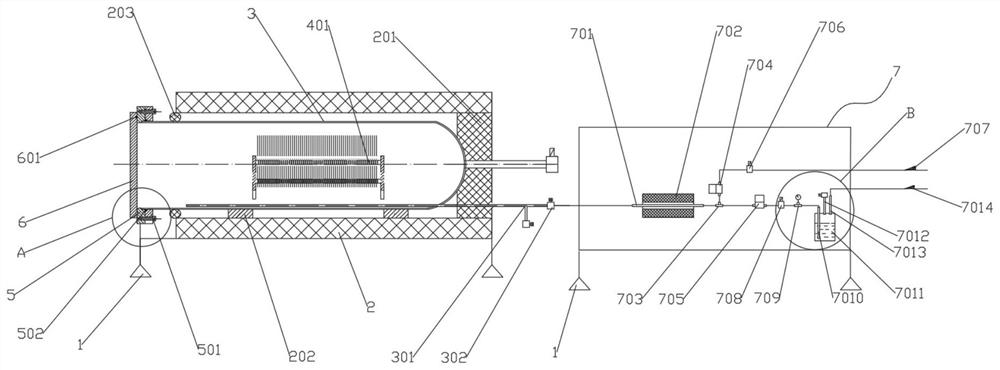

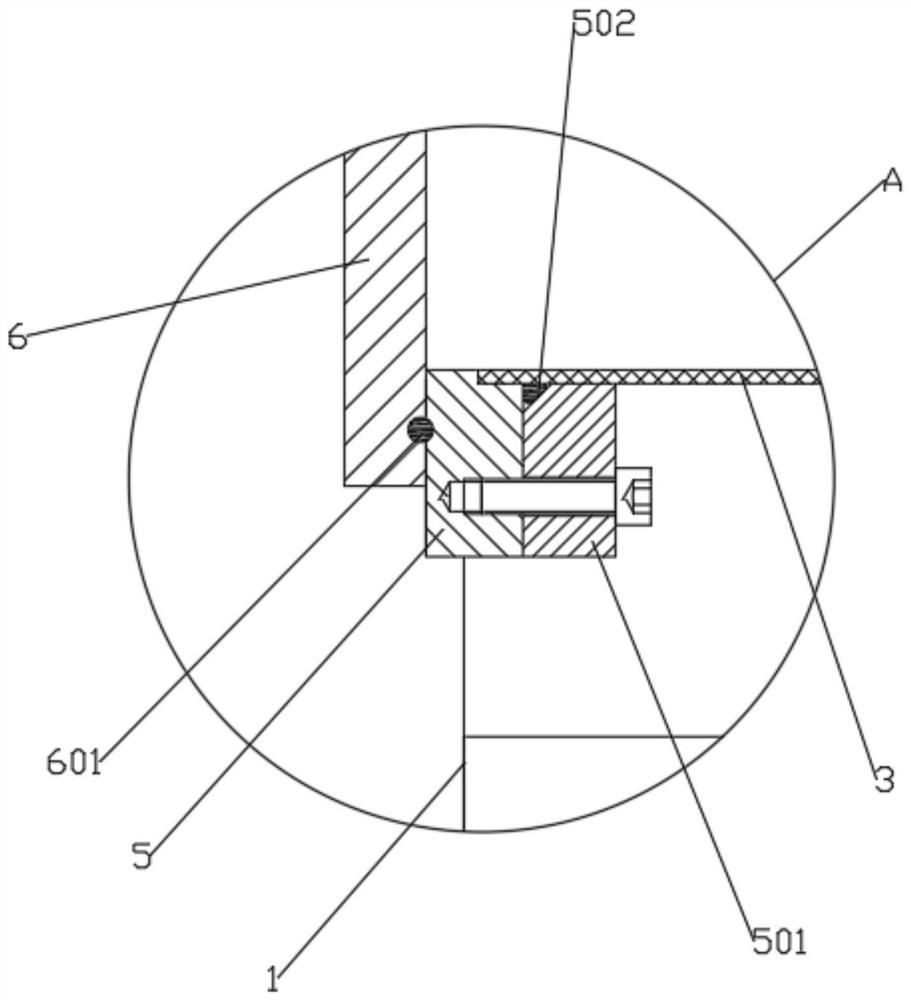

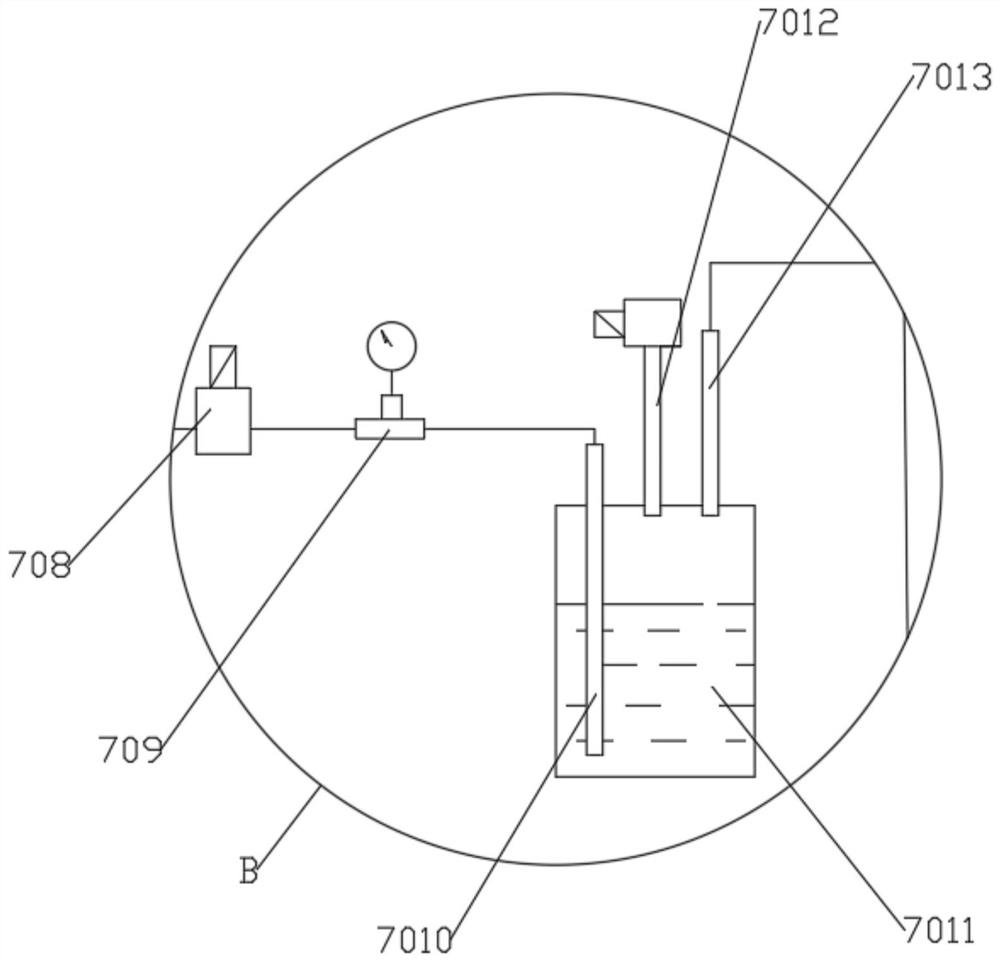

[0019] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 As shown, by the frame body 1, the heater 2 supported by the frame body 1, the inside of the heater 2 is coaxially installed with the process tube 3 (process furnace) through the pad 202, and the crystal boat 401 and the wafer 402 are placed on the process tube 3 (process furnace). Furnace), the process furnace mouth flange 5 supported by the frame, the process tube 3 sealing flange, and the process tube 3 sealing ring are used to seal and install the process tube 3 (process furnace) nozzle, and the swing furnace door 6 passes through the furnace The door sealing ring and the process furnace mouth flange 5 realize the furnace door sealing, the tail heat insulation plug is used to block the heat dissipation at the tail of the heater 2, and the mouth insulation soft block 203 is used to block the heater 2 and the process tube 3 (process furnace) The gap between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com