Porous dielectric particle, electrode for lithium ion secondary battery, and lithium ion secondary battery

A secondary battery, dielectric technology, applied in the field of lithium ion secondary batteries, can solve the problems of reduced lithium ion conductivity, increased internal resistance, insufficient amount of electrolyte, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

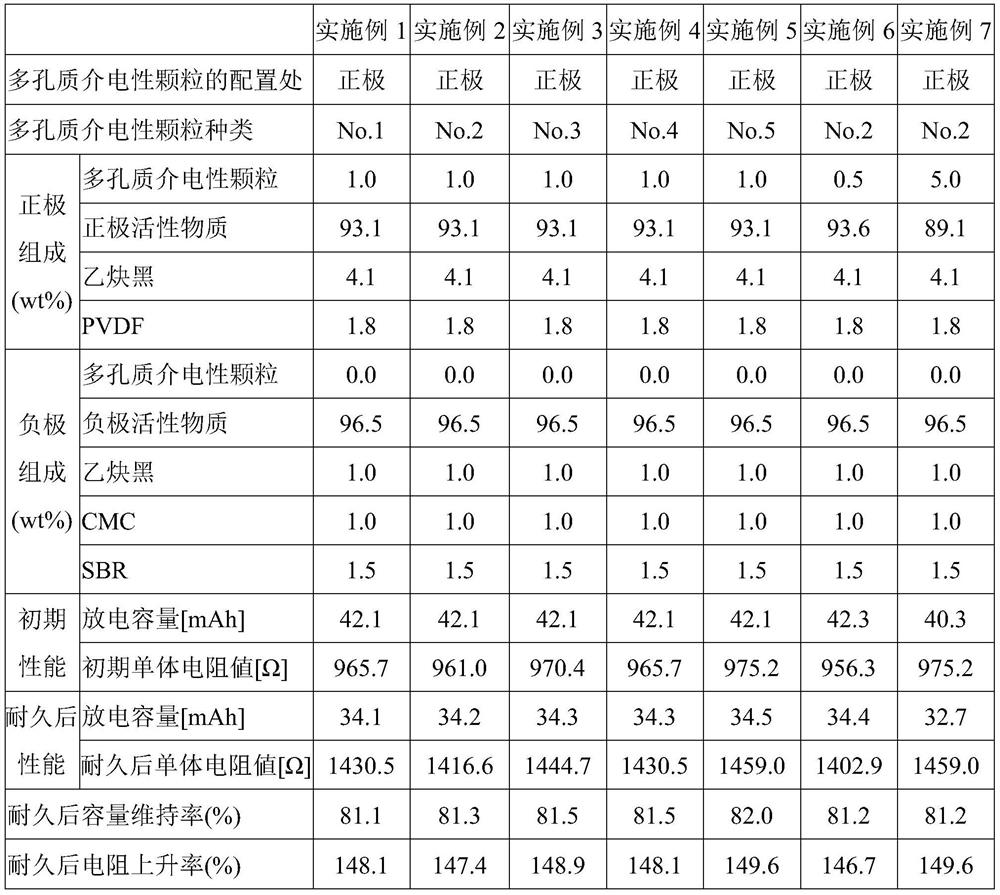

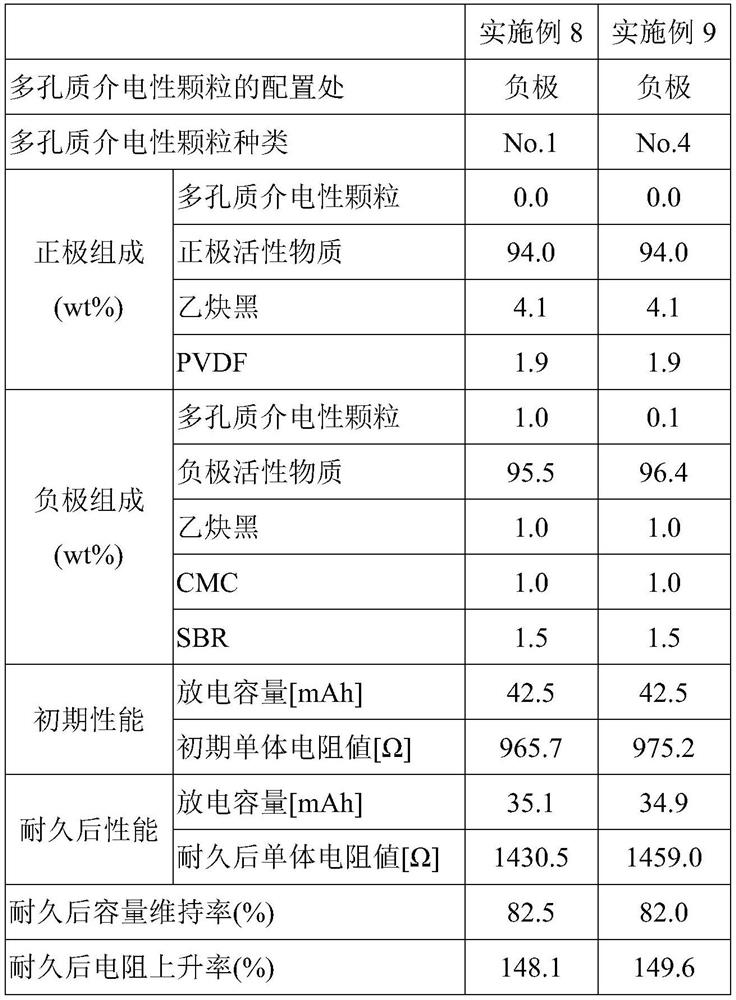

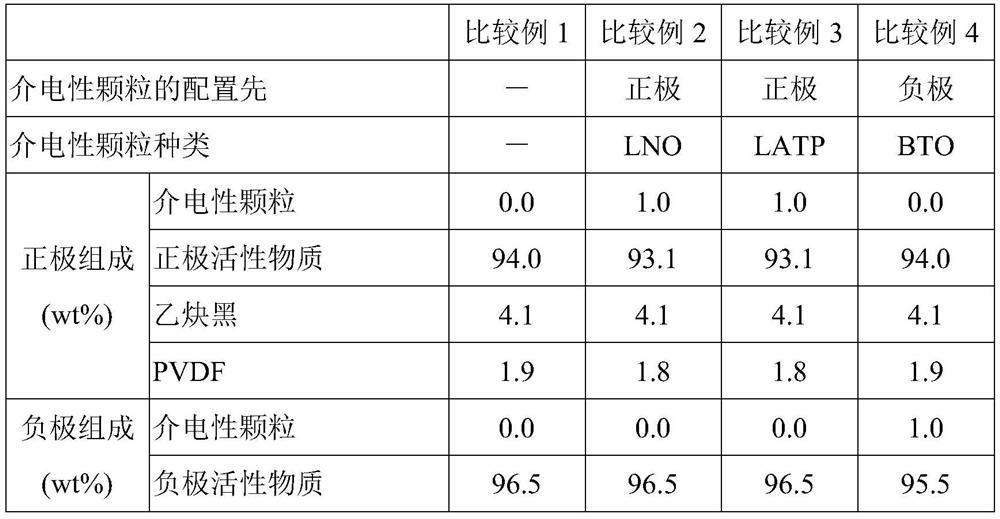

Embodiment 1~9、 comparative example 1~4

[0224] [making of positive electrode]

[0225] Mix porous dielectric particles or dielectric oxide particles, acetylene black (AB) as a conductive additive, and polyvinylidene fluoride as a binder with the composition shown in Table 1 to Table 3, using a self-rotating revolving mixer. Ethylene (PVDF), N-methyl-2-pyrrolidone (NMP) as a solvent, thereby obtaining a premixed slurry. Next, NCM622 as the positive electrode active material and the pre-mixed slurry were mixed so as to have the compositions shown in Tables 1 to 3, and dispersed using a planetary mixer to obtain a positive electrode paste.

[0226] The obtained positive electrode paste was coated on one side of an aluminum current collector with a thickness of 15 μm, and after drying in a vacuum at 120° C. for 10 minutes, it was pressed with a linear pressure of 1 t / cm by a roller press, and further , and dried in a vacuum at 120° C., thereby producing a positive electrode for a lithium ion secondary battery.

[0227...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com