Radio frequency superconducting resonant cavity based on high heat conduction material and high radio frequency performance superconducting material composite board and preparation method thereof

A technology of superconducting resonant cavity and superconducting material, applied in the field of radio frequency superconducting resonant cavity and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

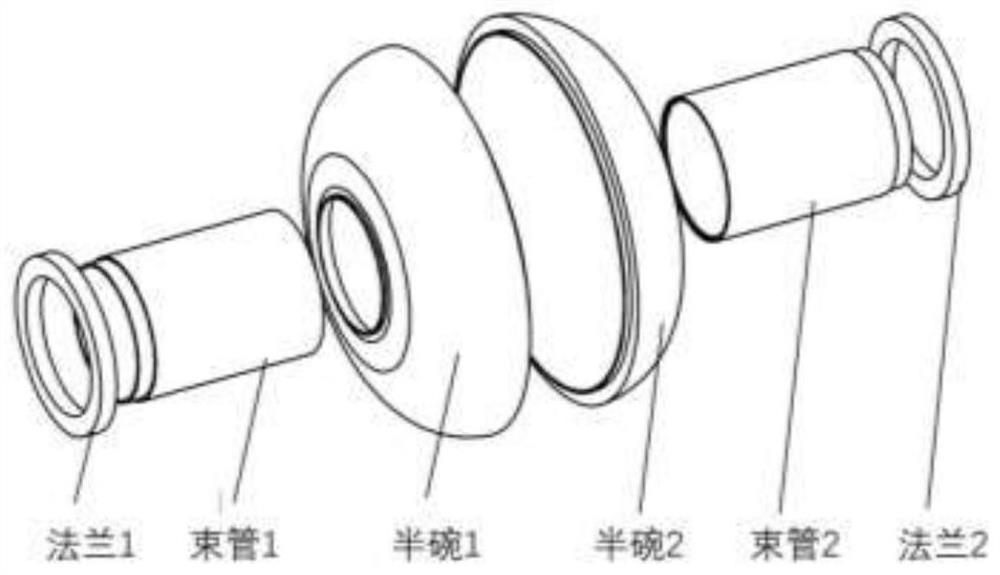

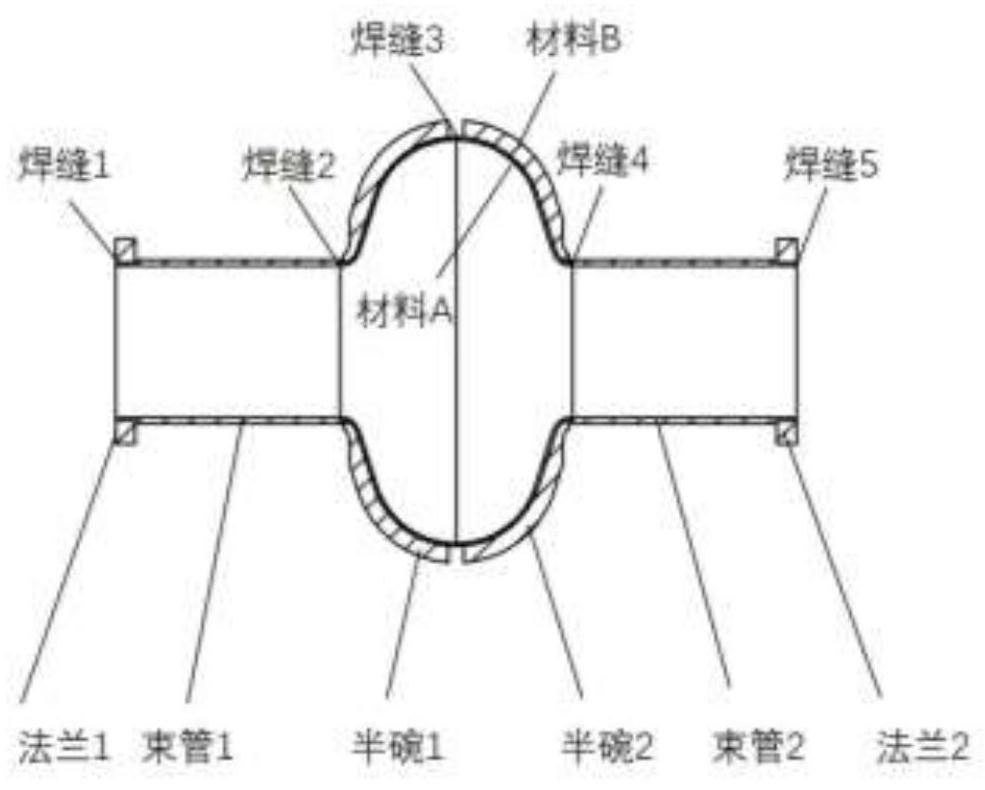

[0028] Taking a 1.3GHz single-unit ellipsoidal cavity as an example, the high-performance double-layer material composite superconducting cavity and its preparation method involved in the present invention are described. The exploded view of the components of the 1.3GHz single-unit ellipsoid composite superconducting cavity is shown in figure 1 As shown, the cross-sectional view is shown as figure 2shown. Material A is selected as high-purity niobium with high radio-frequency superconductivity and RRR>300. High-purity niobium has low radio-frequency surface resistance, a critical temperature of 9.25K, and a thermodynamic critical magnetic field of 240mT; material B is TU0 with high thermal conductivity. Copper oxide has a thermal conductivity of about 600W / m·K at 4.2K, which is an order of magnitude higher than that of high-purity niobium. The following steps were used to develop a 1.3GHz single-unit ellipsoidal TU0 oxygen-free copper and high-purity niobium double-layer ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com